The method of making a hollow layer with observable structural leakage in the wall and bottom plate of underground engineering

A technology for underground engineering and observation of structures, which is used in infrastructure engineering, protection devices, buildings, etc., and can solve the problems of underground engineering waterproofing without a specified warranty period and waterproofing principle defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

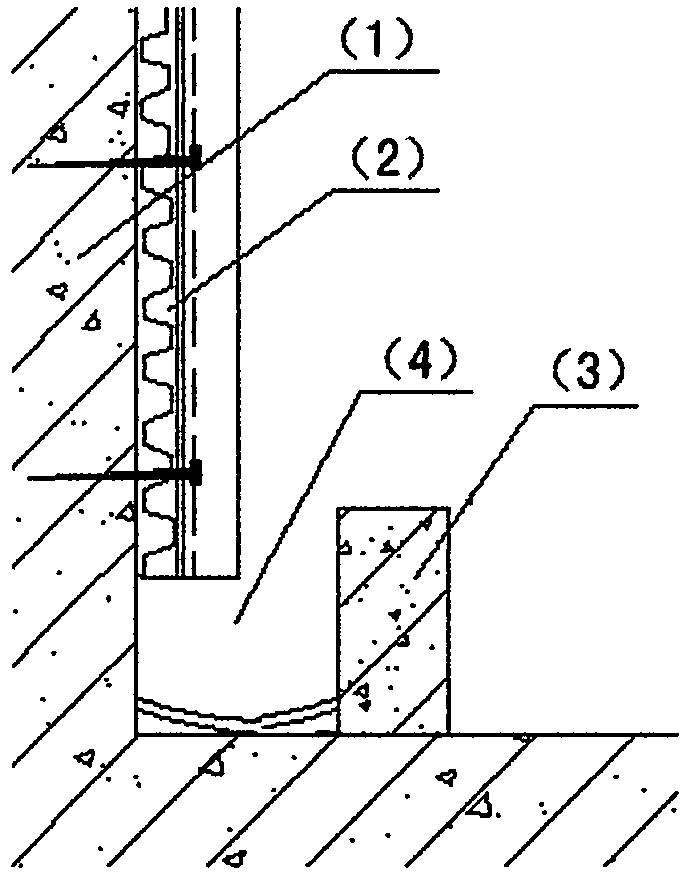

[0019] figure 1 1. The interior of the structural wall 1 is the hollow wall surface 2 of the drainage board, and there is a drainage ditch guide wall 3 on the ground. From the open wall surface seepage drainage ditch 4, the specific position where the wall seepage water flows out from the hollow layer can be seen.

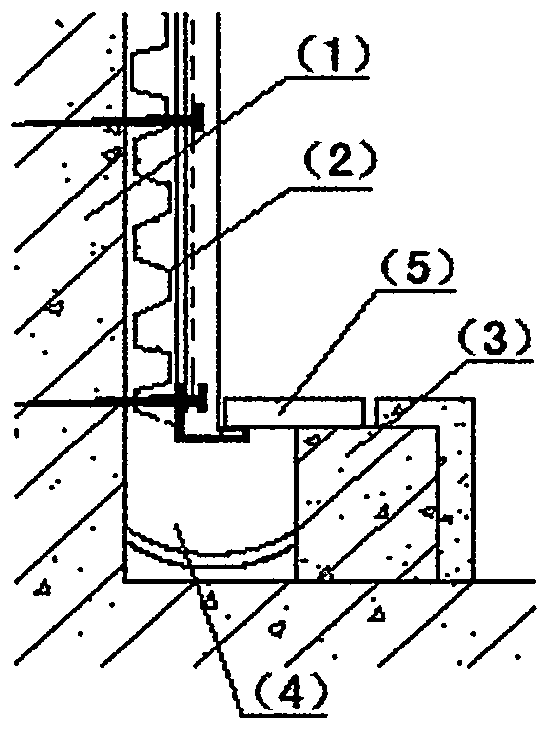

[0020] figure 2 ,and figure 1 The structure is the same, except that there is a horizontally placed wall observation cover plate 5 above the open wall seepage drain 4.

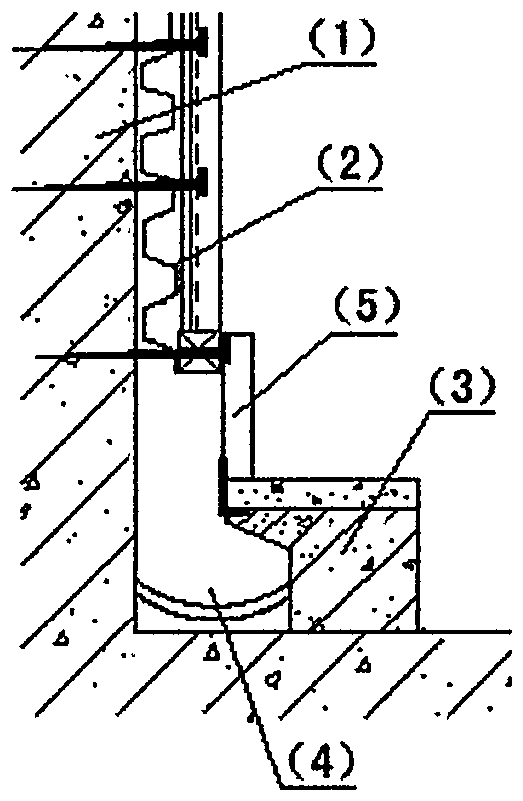

[0021] image 3 ,and figure 1 The structure is the same, but there is a vertically installed wall observation cover plate 5 above the open wall seepage drain 4.

[0022] Figure 4 ,above figure 1 , figure 2 , image 3 The metope seepage water flows into ground sump well 6 from metope seepage drain ditch 4, and metope seepage water storage tank 7 is installed earlier at the sump well edge, and just flows into sump well 6 when metope seepage overflows from the water storage tank. Also can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com