Efficient soil breaking drill bit

A drill bit, high-efficiency technology, applied in the direction of drill bits, earthwork drilling, drilling equipment, etc., can solve the problems of hard-to-break soil and poor soil-breaking effect, and achieve good soil-breaking effect, not easy to stall, and low power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

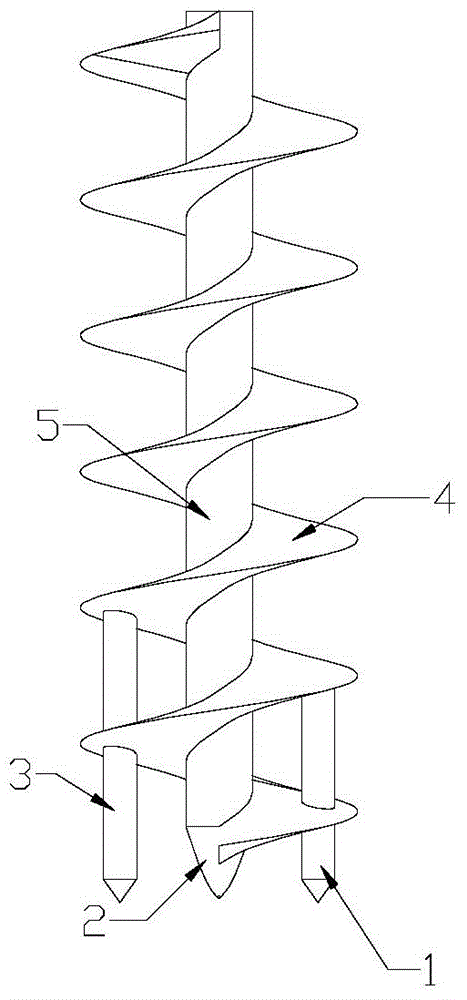

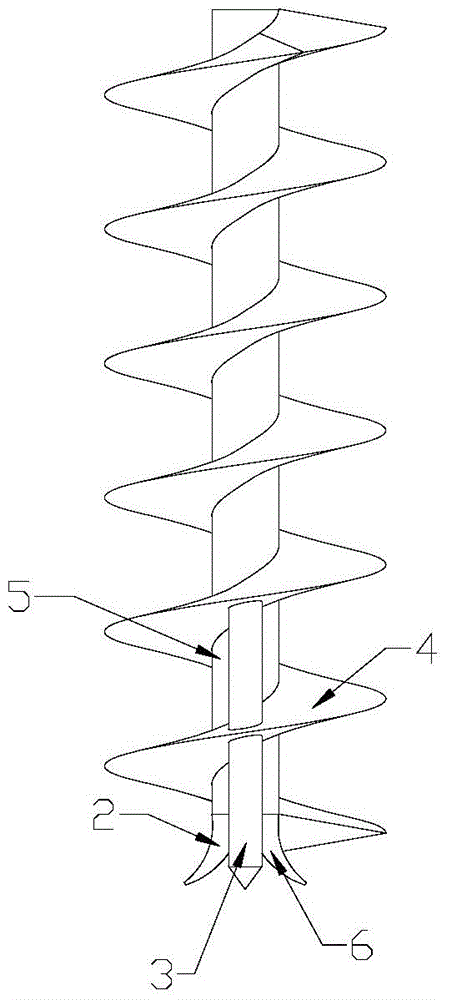

[0023] The high-efficiency ground-breaking bit includes a main shaft 5, a spiral guide vane 4 connected to the main shaft, and a ground-breaking end; the ground-breaking end includes an outer ground-breaking end 1, an outer ground-breaking end 3, a central ground-breaking end 2, and a central soil-breaking end 6; the outer ground-breaking ends 1 and 3 are fixed At the symmetrical position of the spiral guide vane 4, the central soil-breaking ends 2 and 6 are connected to the end of the drill bit main shaft 5, the connection line of the outer soil-breaking ends 1 and 3 is perpendicular to the connection line of the central soil-breaking ends 2 and 6, and the work of the outer soil-breaking ends The radius is larger than the working radius of the central ground-breaking end, and the space distribution of the four ground-breaking ends is even in the working range, increasing the ground-breaking area. The central soil-breaking ends 2 and 6 are bifurcated structures with a central a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com