An all-in-one machine for tillage, ridge and film covering, and a tillage, ridge and film covering system

An all-in-one machine and film-covering technology, which is applied in the field of farming ridge film-covering machine and tillage film-covering system, can solve problems such as weak film pressure, pollution of film laying costs, and fragility of ridge piles, etc., to achieve Improve applicability, good soil-breaking effect, good soil-breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

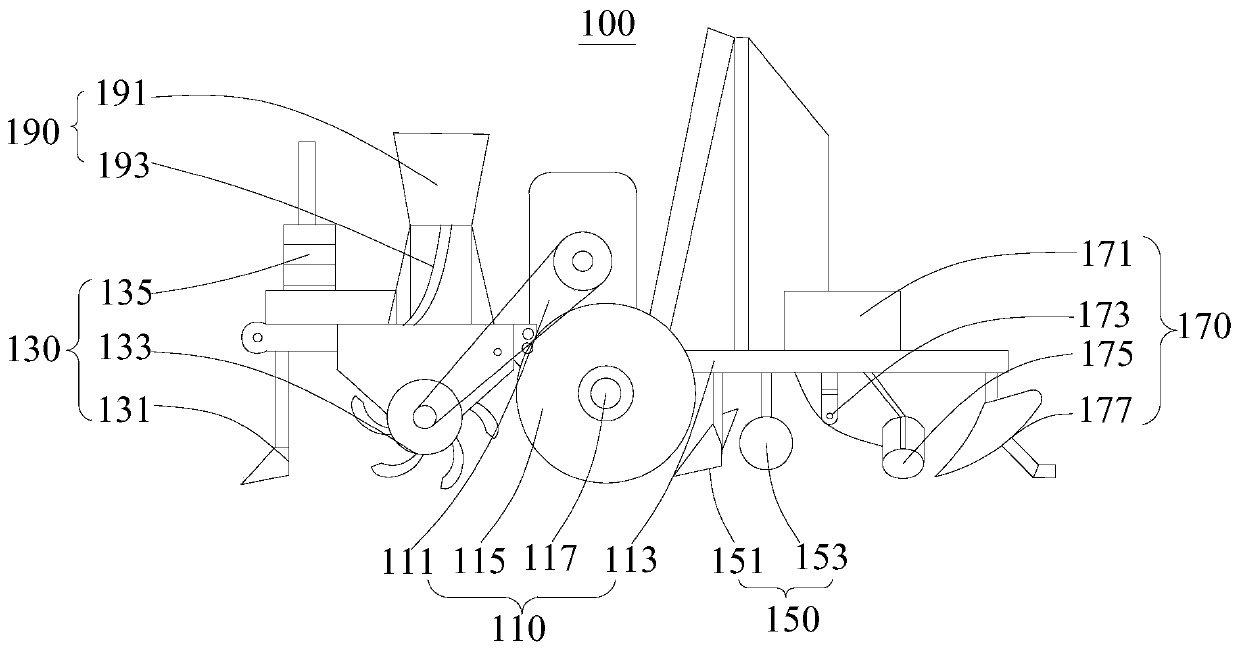

[0035] refer to figure 1 , this embodiment provides a tillage ridge filming system (not shown), including a tractor (not shown), a driving device (not shown) and a tillage ridge filming integrated machine 100, the tractor and tillage The all-in-one ridge forming and film covering machine 100 is connected, and the driving device is detachably installed on the tractor and connected with the all-in-one tillage and film covering machine 100 to provide power for the all-in-one tillage and film-covering machine 100 .

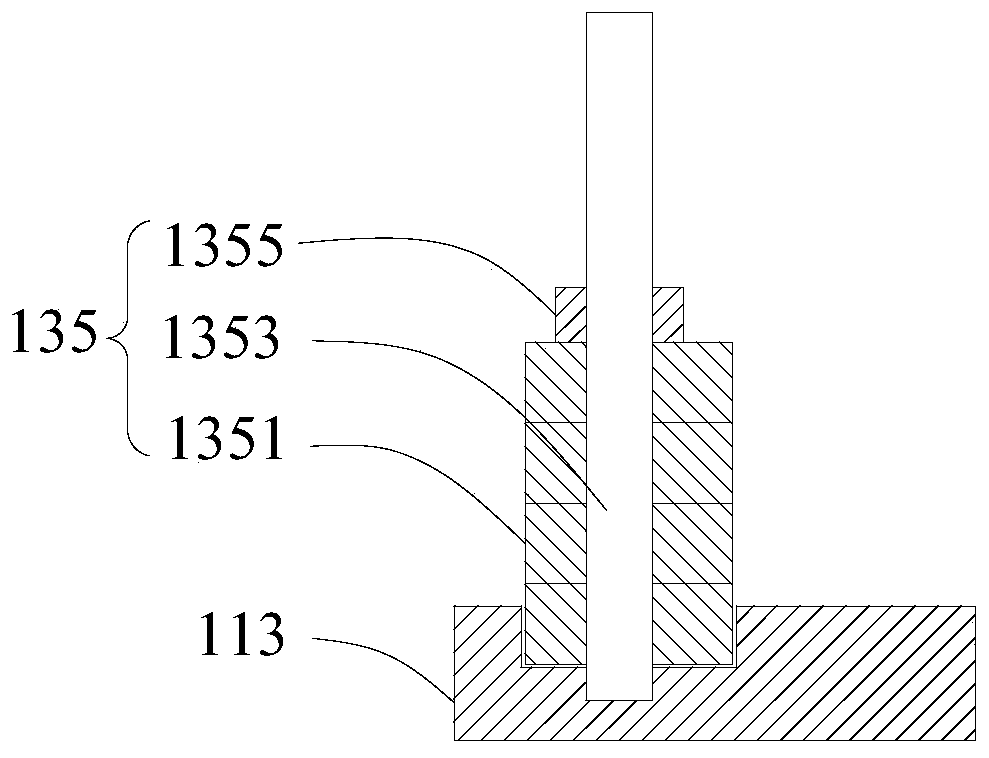

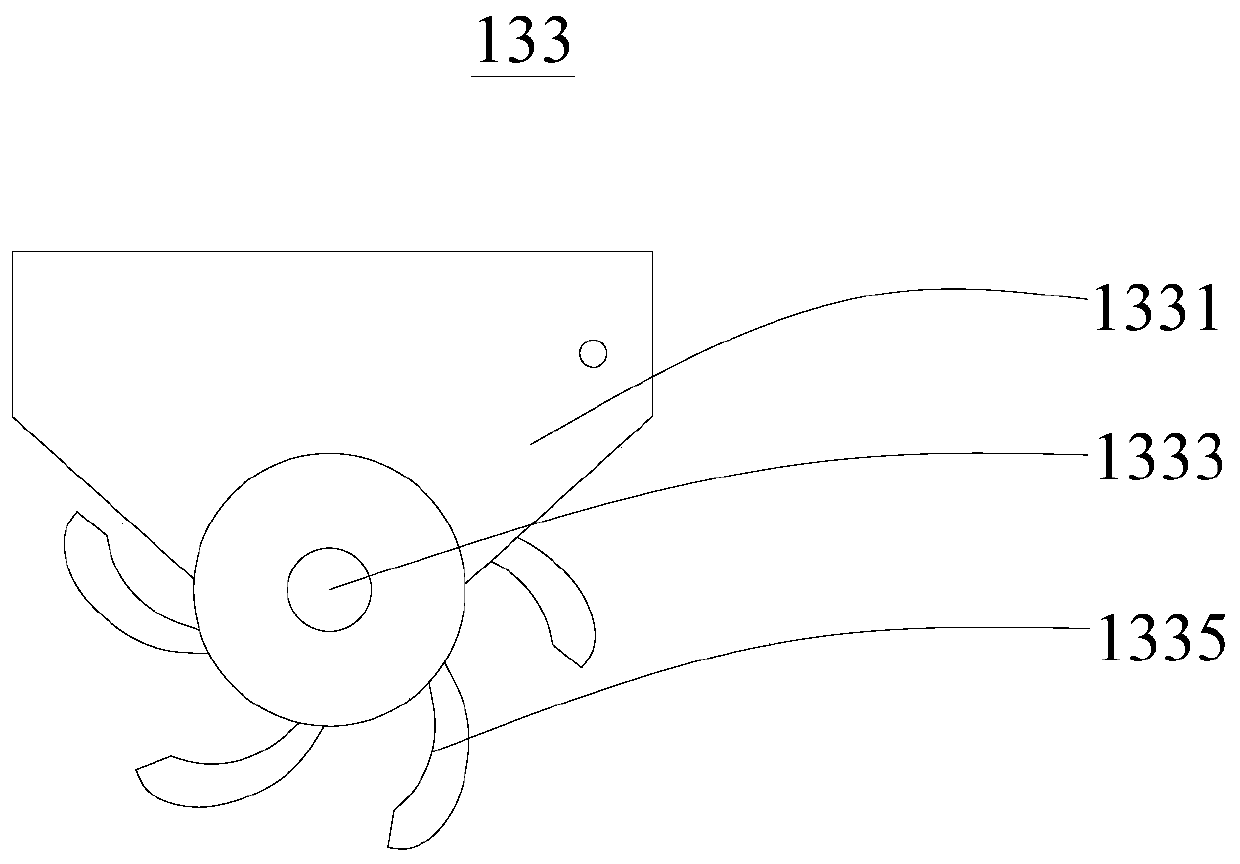

[0036] The all-in-one tillage, ridge and film covering machine 100 includes a load-bearing vehicle body 110, a soil loosening device 130, a ridging device 150, a film covering device 170, and a fertilization device 190, and the soil loosening device 130, the fertilization device 190, a ridging device 150, and a film covering device 170 is sequentially connected to the carrying vehicle body 110 and is driven forward by the carrying vehicle body 110 .

[0037] The carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com