Vehicle flexible drive plate with torsion damper

A technology of torsional shock absorber and shock absorber, which is applied in the direction of vibration suppression adjustment, spring/shock absorber, and components with teeth, etc., which can solve the problems of costly and low-cost goals, and achieve performance without sacrificing performance. Small material and assembly cost, effect of avoiding resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the drawings, the same reference numerals are used to describe the same components. In the following description, various operating parameters and components are described for differently constructed embodiments. These specific parameters and components are included in this specification as examples and not meant to be limiting.

[0025] In general, the present invention is a flexible driving disc composed of a driving disc and a driven disc connected by springs and riveted to each other. This spring arrangement forms a shock absorber.

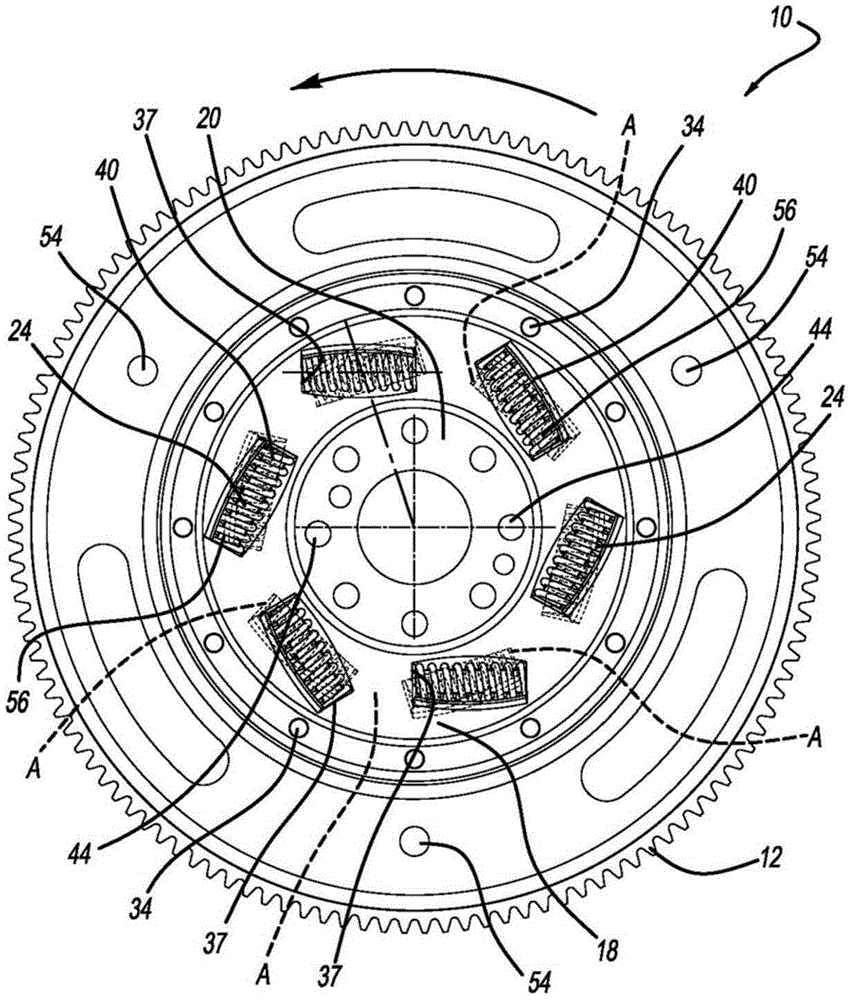

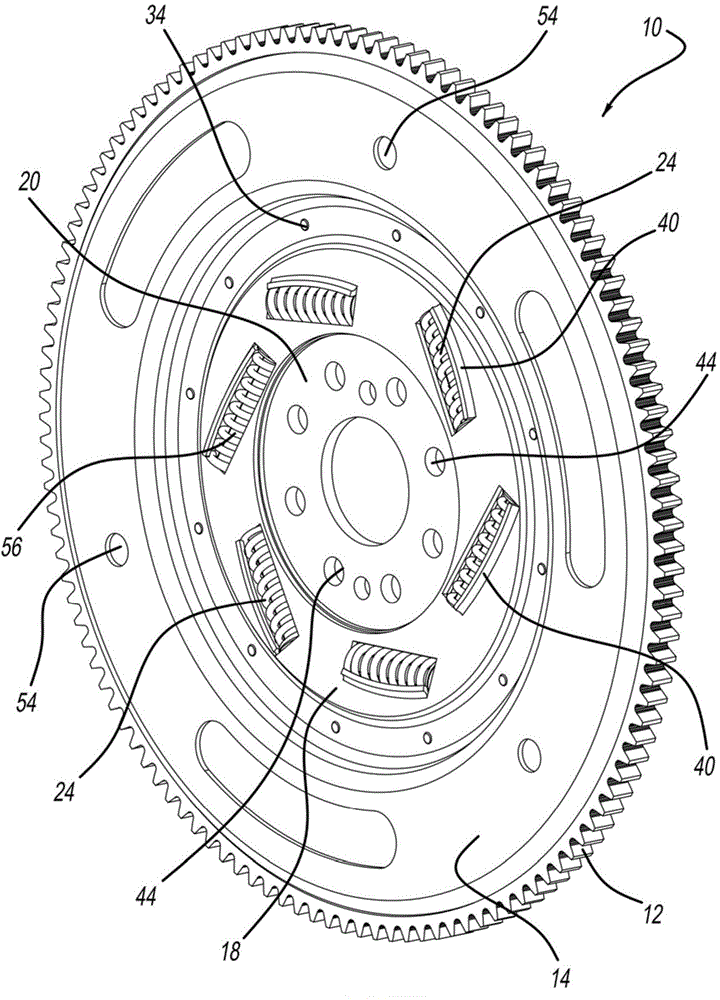

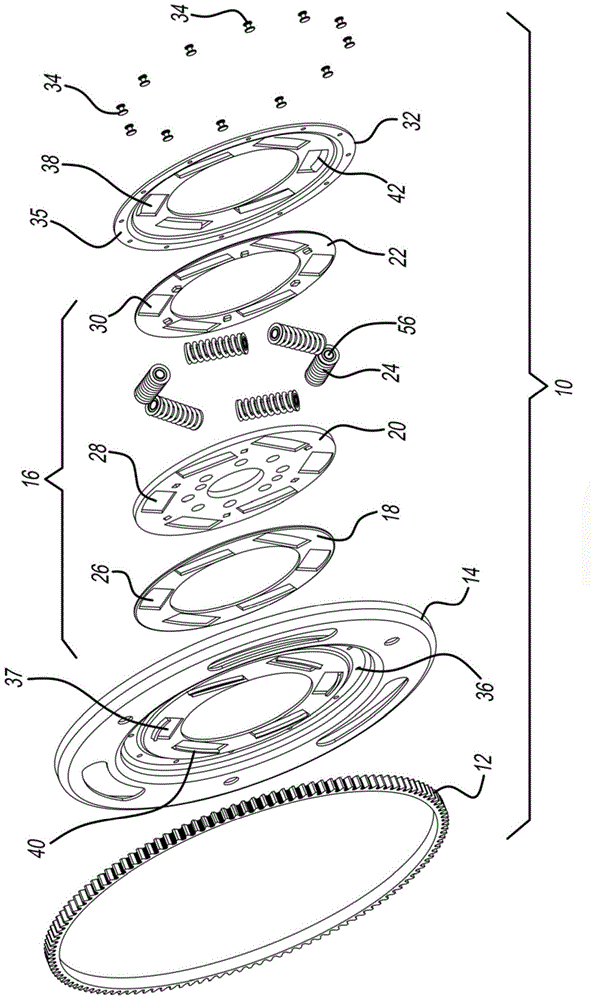

[0026] More specifically, refer to Figures 1 to 4 , show end and perspective views, respectively, of the flexible drive disk assembly, generally illustrated at 10 . The flexible drive plate assembly 10 includes a ring gear 12 mounted on a driven plate 14 for selective engagement with a starter motor (not shown).

[0027] Inside the flexible driving disc assembly 10 is a damping assembly 16 including a first friction disc 18 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com