Push-pull type fluid connector

A connector, push-pull technology, applied in the field of push-pull fluid connectors, can solve the problems of slow separation operation, unstable connection, etc., and achieve the effects of rapid operation, improved flow capacity, and large contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

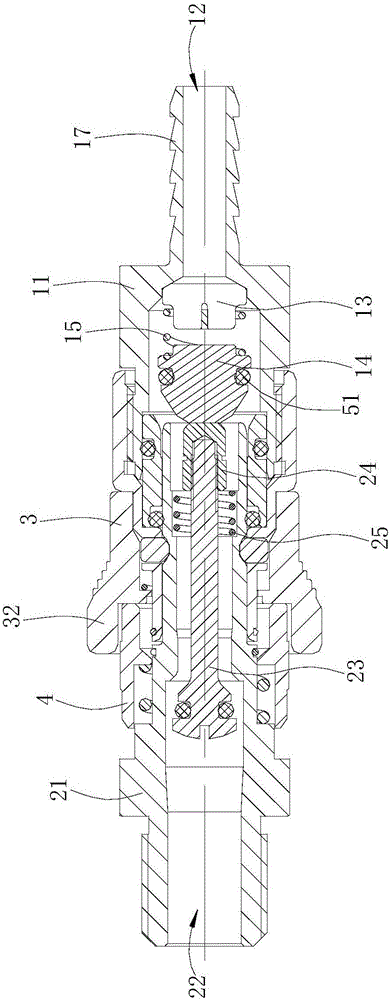

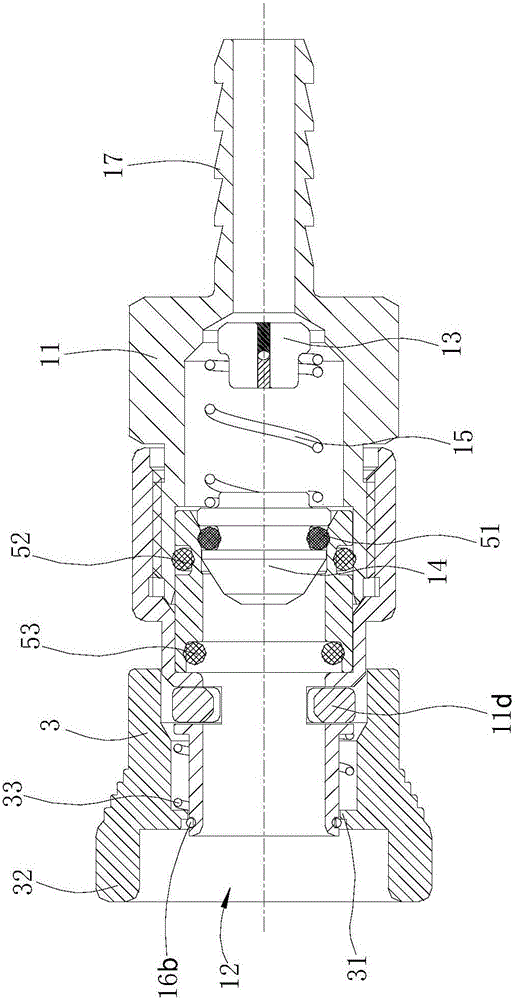

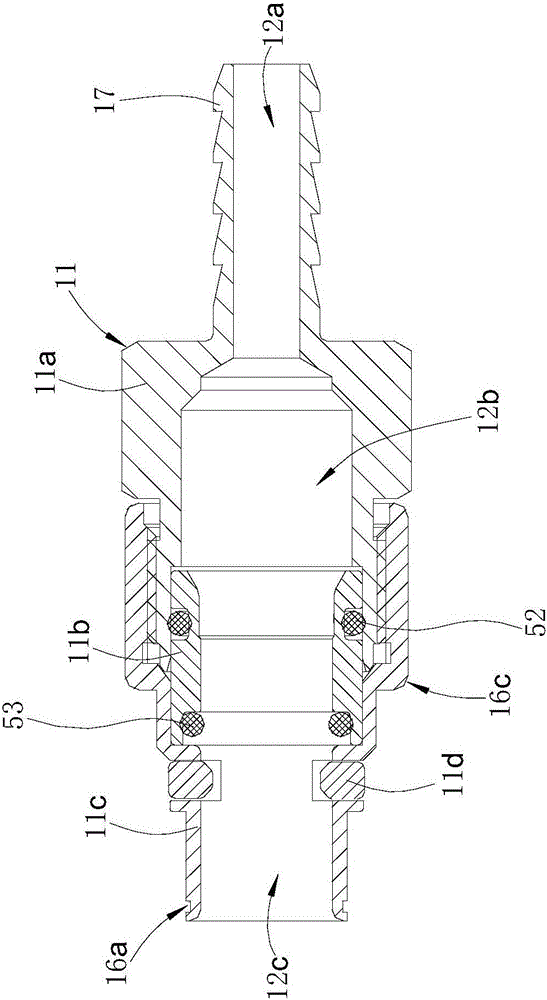

[0021] Such as Figures 1 to 5 shown

[0022] The fluid connector includes a receptacle and a plug mated with the receptacle.

[0023] The plug includes a housing 11, an annular support piece 13, a first valve core 14, a block 11d and a first return spring 15. The housing 11 is assembled from three sleeves, and the three sleeves are respectively the first sleeve 11a , the second casing 11b and the third casing 11c, the structure of three casings is used to make the casing 11 more convenient to assemble and reduce the difficulty of processing. The front part of the casing 11 is provided with a corrugated protrusion 17 that cooperates with the external hose;

[0024] The housing 11 has a first diversion hole 12 that runs through the front and rear end surfaces of the housing 11. The first diversion hole 12 is a three-stage stepped hole. The first diversion hole 12 is successively composed of the first stage hole 12a, The second-stage hole 12b and the third-stage hole 12c are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com