Strain measuring method based on Moire fringe phase analysis

A moiré fringe and strain measurement technology, applied to measuring devices, instruments, optical devices, etc., can solve the problems of high working environment requirements, long measurement time, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings and theoretical derivation.

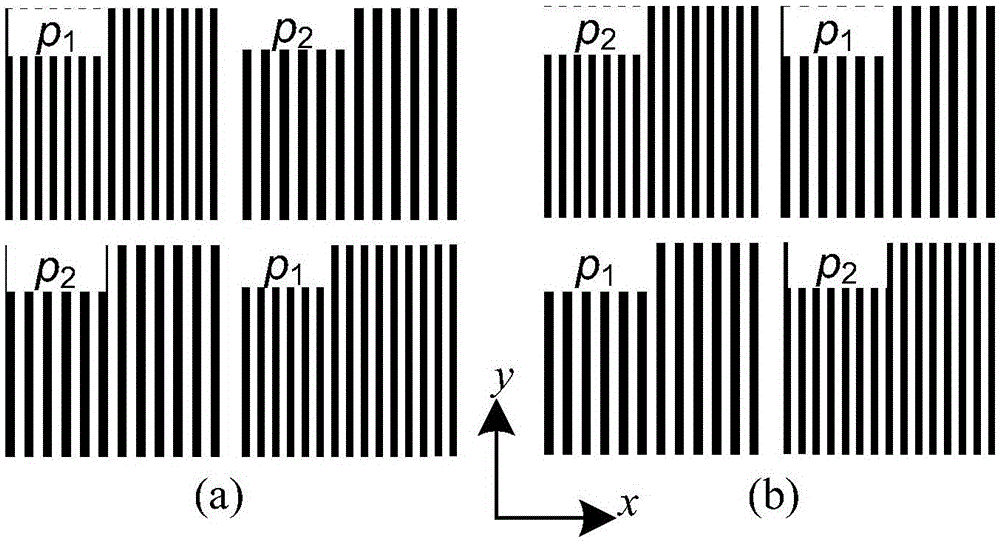

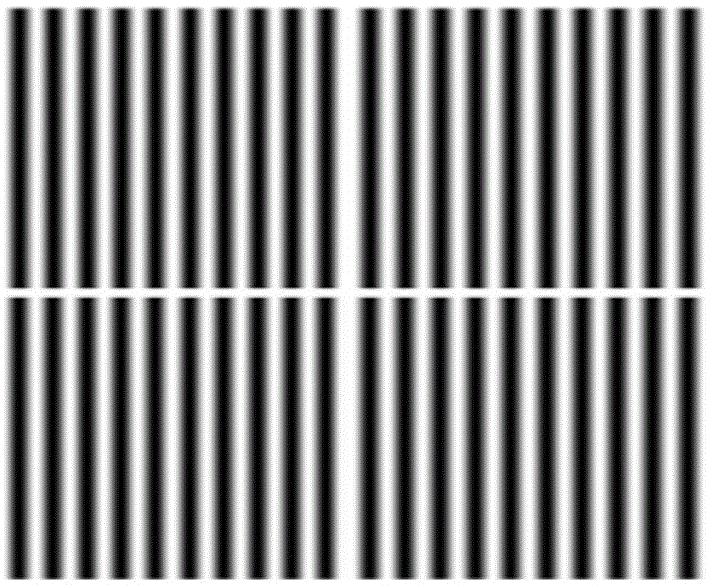

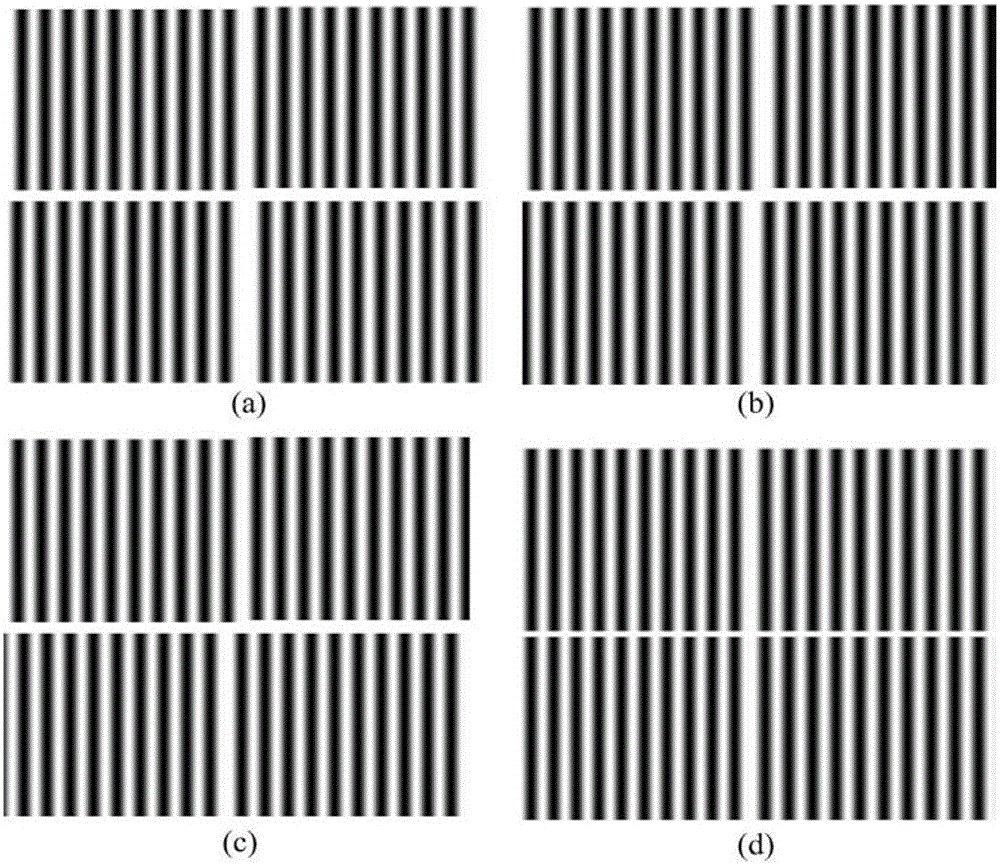

[0017] In the strain measurement method based on the phase analysis of moiré fringes, high detection accuracy can be obtained by detecting the relative displacement or phase shift of the upper and lower two groups of moiré fringes during measurement.

[0018] First, the 530nm illumination light is used, processed by the beam expander collimator, and then passed through the diaphragm, and then the 530nm illumination light is projected onto the object grating G1.

[0019] Assuming that the period size of the object grating G1 is P1, after the illumination light passes through the object grating G1, it passes through a double-telecentric system to reflect an inverted image in equal proportions, and reflects it to the surface of the object under test through the triangular mirror on the left, and then passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com