Laser-Doppler-effect-based feed depth measuring system for drilling rod of coal mine gas drilling machine

A technology of Doppler effect and coal mine gas is applied in the field of drill pipe feed depth measurement system of coal mine gas drilling rig to achieve the effects of improving measurement reliability and accuracy, ensuring safety and avoiding interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained by specific examples below.

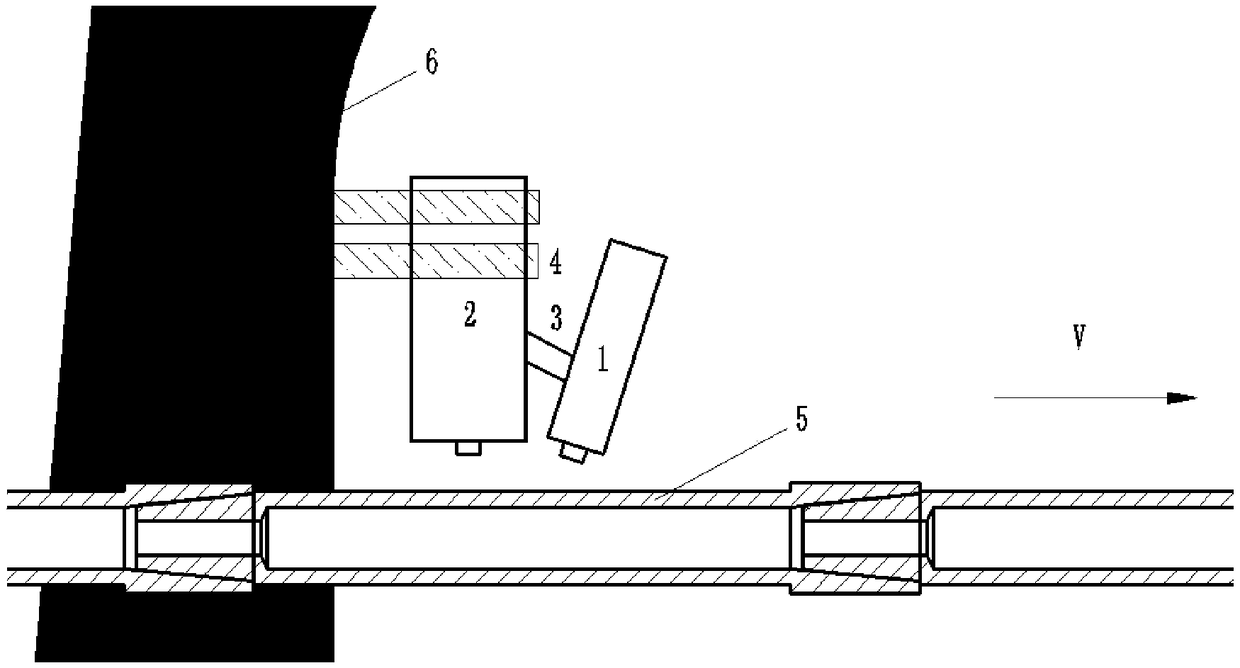

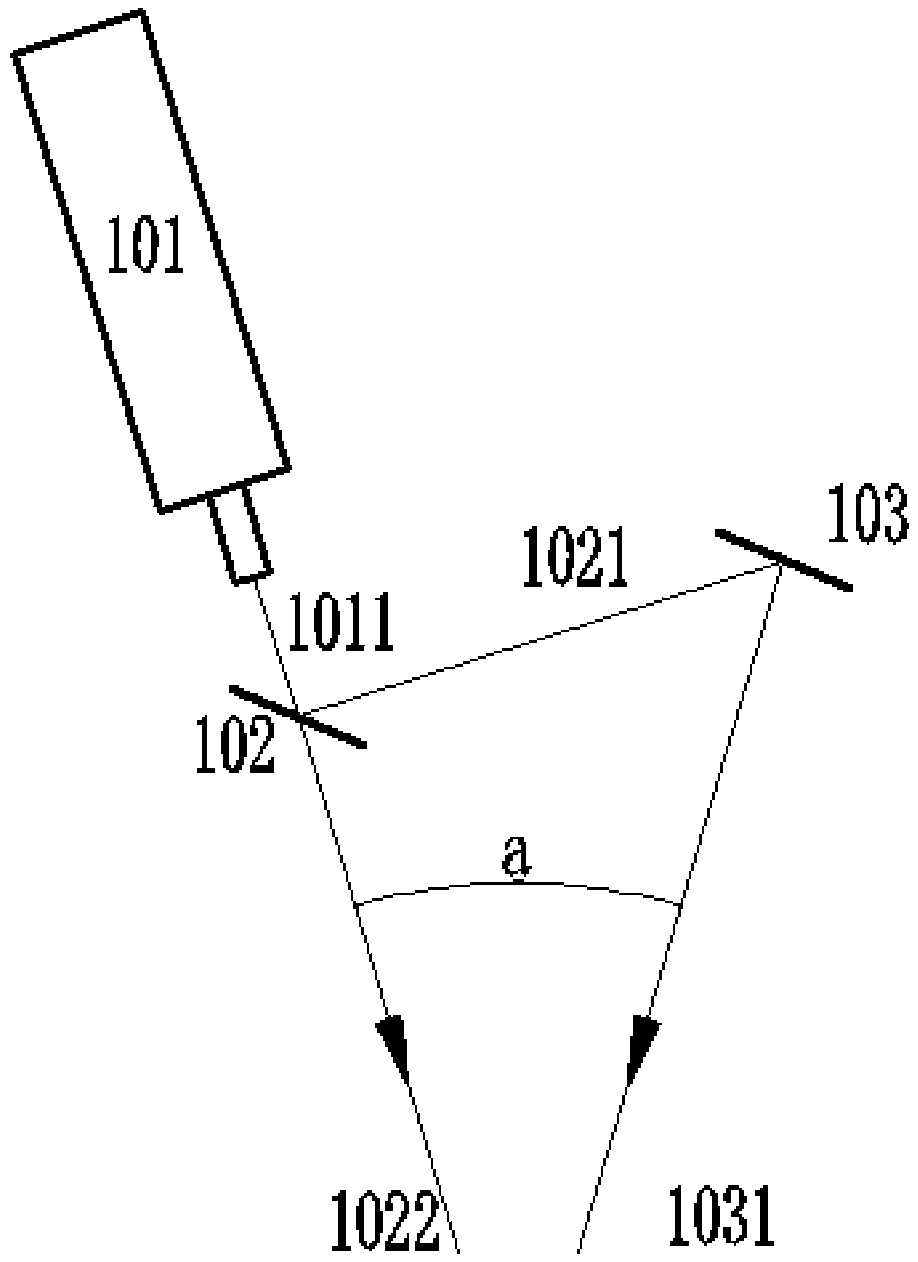

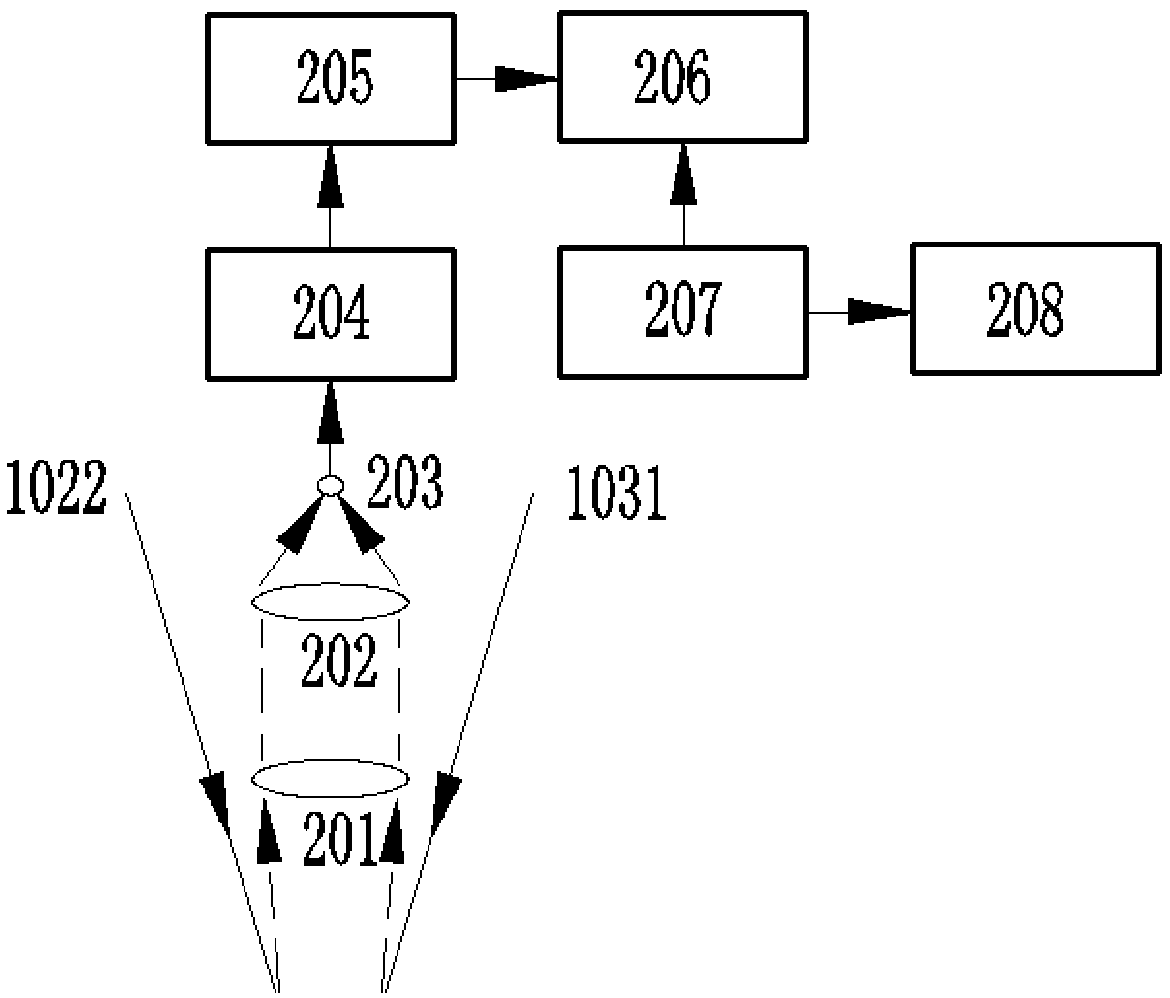

[0025] see figure 1 A coal mine gas drilling rig drill pipe feed depth measurement system based on the laser Doppler effect, including an optical path module 1, a frequency shift detection and processing module 2, a component connection module 3, and a coal and rock fixing module 4. The optical path module 1 is packaged in a cylindrical Inside the shell and on the outside of the system, it is used to provide two beams of laser beams at a fixed angle; the frequency shift detection processing module 2 is packaged in the cylindrical shell and aligned with the surface of the drill pipe, and is used to collect the laser beams irradiated on the moving drill pipe 5 to generate Scattered light, measure the Doppler frequency shift, and then automatically measure the real-time speed in the extraction process of the drill rod 5, and calculate the real-time length of the drill rod 5 after integration and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com