A Geological Drill Pipe Feed Depth Measurement System Based on Aberration Analysis of Drill Pipe Nodes

A technology of rod feeding and drilling rod, which is applied in the field of geological drill rod feeding depth measurement system, can solve the problems of data falsification, inability to accurately identify periodic jumps, etc., to improve accuracy, improve measurement reliability and accuracy, The effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained by specific examples below.

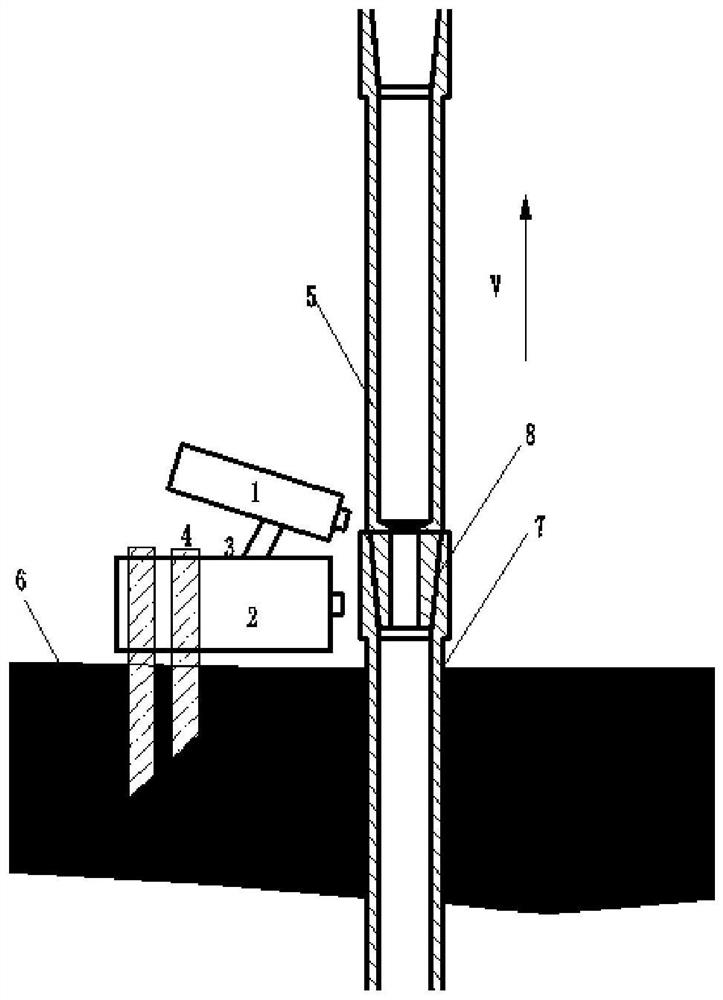

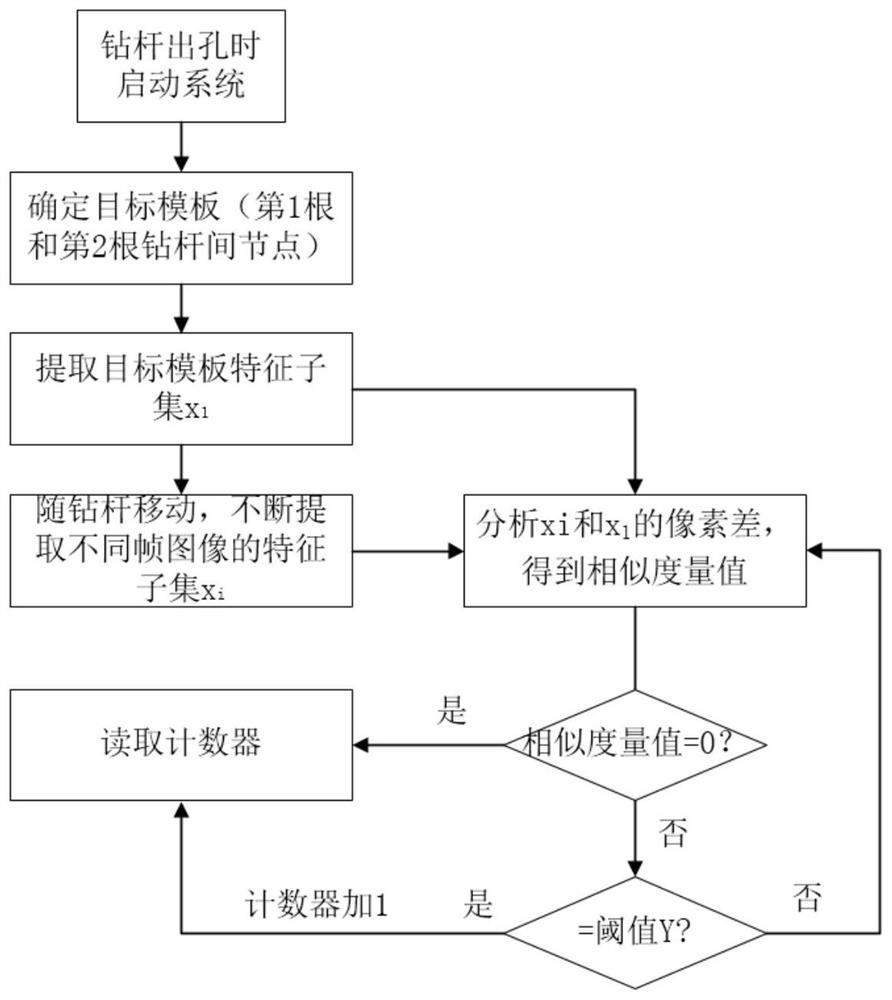

[0026] see figure 1 A geological drill pipe feed depth measurement system based on aberration analysis of drill pipe nodes, including an LED lamp 1, an image processing module 2, a component connection module 3, and a surface fixing module 4; the LED lamp 1 is packaged in a cylindrical shell And it is arranged on the outside of the system, and directly shines on the surface of the drill pipe 5; the image processing module 2 is packaged in a cylindrical shell and aligned with the surface of the drill pipe 5, and is used at the hole exit 7 during the drilling process after the drilling machine completes the drilling. A camera takes continuous pictures of the drill pipe 5, automatically compares and recognizes the changes of the two frames before and after the surface of the drill pipe 5, analyzes the node shape of the joint 8 of the drill pipe by aberration, completes the count of the drill pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com