A gear early fault detection method

A technology of early failure and detection method, applied in the direction of machine gear/transmission mechanism testing, special data processing applications, instruments, etc., can solve the problems of no established condition monitoring method, lack of analysis, and no proposed rotating machinery condition assessment criteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

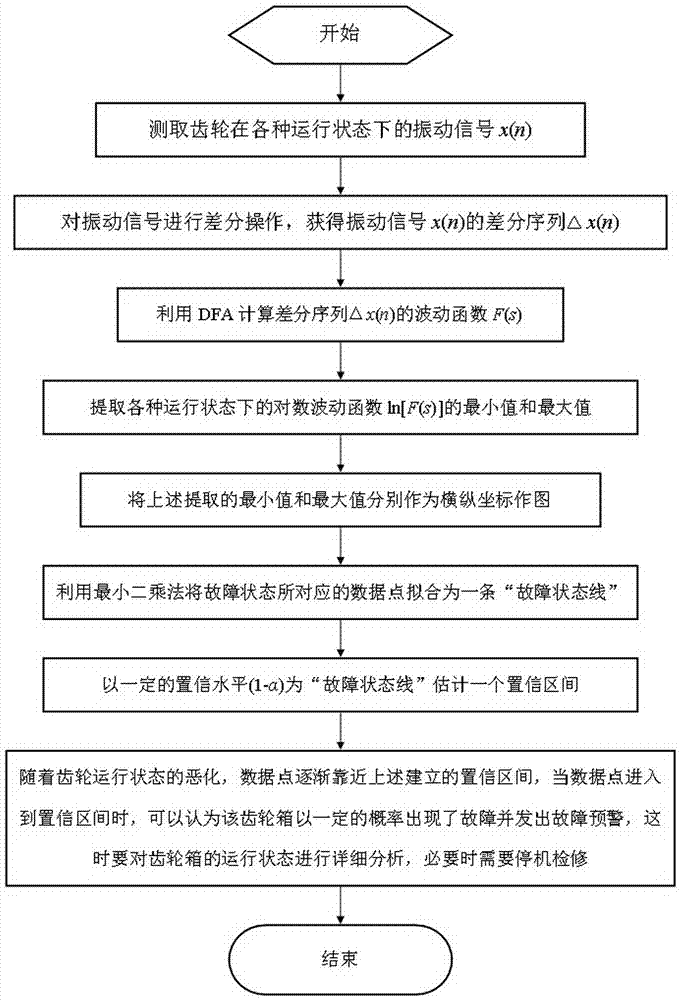

Method used

Image

Examples

Embodiment example 1

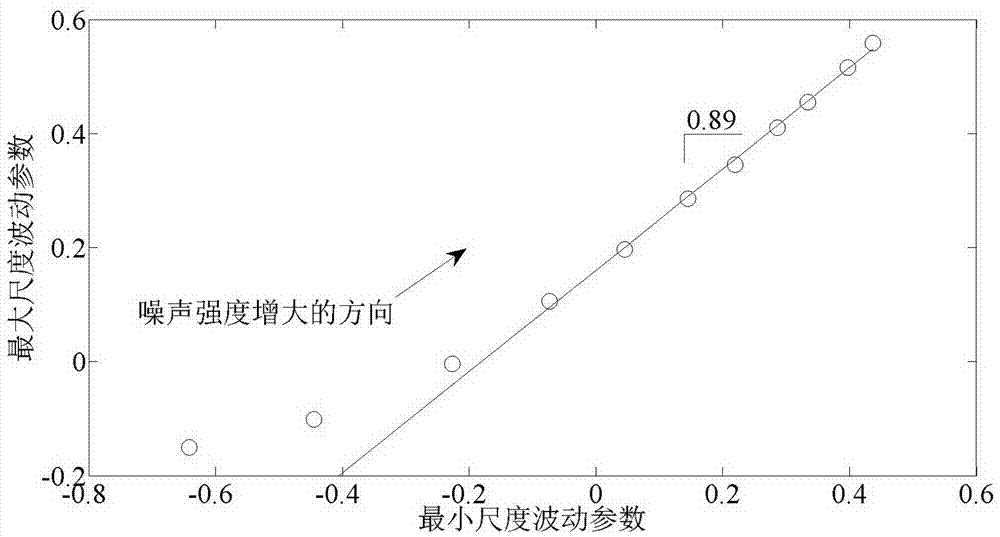

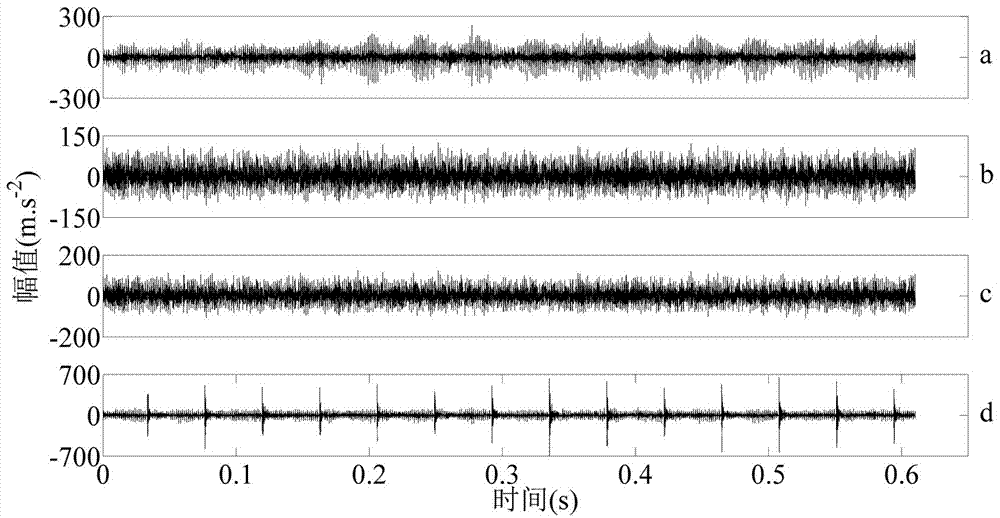

[0038] The practicability of the method of the present invention is verified by using the gear failure data measured from the gearbox test bench. The tooth numbers of the active and passive gears of the gearbox are 24 and 29 respectively, the rotational speed of the active gear is 1420RPM, and the sampling frequency is 16384Hz. Slight wear, moderate wear and broken tooth faults were simulated on the gearbox respectively. Utilize the method described in the present invention to analyze the gear box vibration signal under normal state and above-mentioned three kinds of failure states, the result is as follows Figure 4 shown. From Figure 4 It can be seen that the data points corresponding to the three fault states can be approximately fitted as a "fault state line", while the data points corresponding to the normal state obviously deviate from this straight line. In addition, since the operating state of the gear has a close relationship with the signal-to-noise ratio, gener...

Embodiment example 2

[0040] Gear faults of different severity are manufactured on the experimental gearbox to simulate the evolution process of gear faults. The practicability of the method of the present invention is verified by using the gear fault data collected. The number of teeth of the active and passive gears of the gearbox is 25 and 40 respectively, and a fault is produced on the active gear, and the rotational speed of the active gear is 1600RPM. Slightly scratched, moderately scratched and severely scratched faults were simulated on the gear. Utilize the method described in the present invention to analyze the gear vibration signal under normal state and above-mentioned three kinds of failure states, the result is as follows Figure 6 shown. From Figure 6 It can be seen that the data points corresponding to the three fault states can be approximately fitted as a "fault state line", while the data points corresponding to the normal state obviously deviate from this straight line. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com