Precise temperature control system for friction testing machine

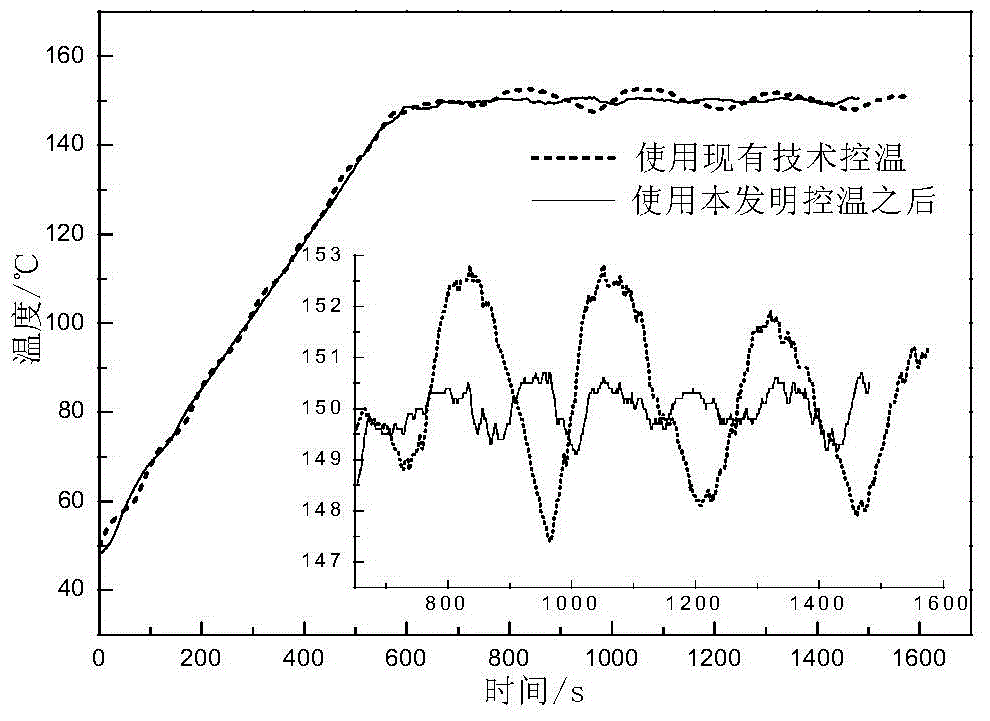

A friction testing machine and temperature control system technology, which is applied in the direction of using electric mode for temperature control, wear resistance test, measuring device, etc., can solve the problem of long and large test cycle, and the general temperature fluctuation is ±3℃~±5℃ , The friction testing machine has no problems such as rapid cooling device, which can shorten the test period, stabilize the constant temperature process, and optimize the temperature control conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

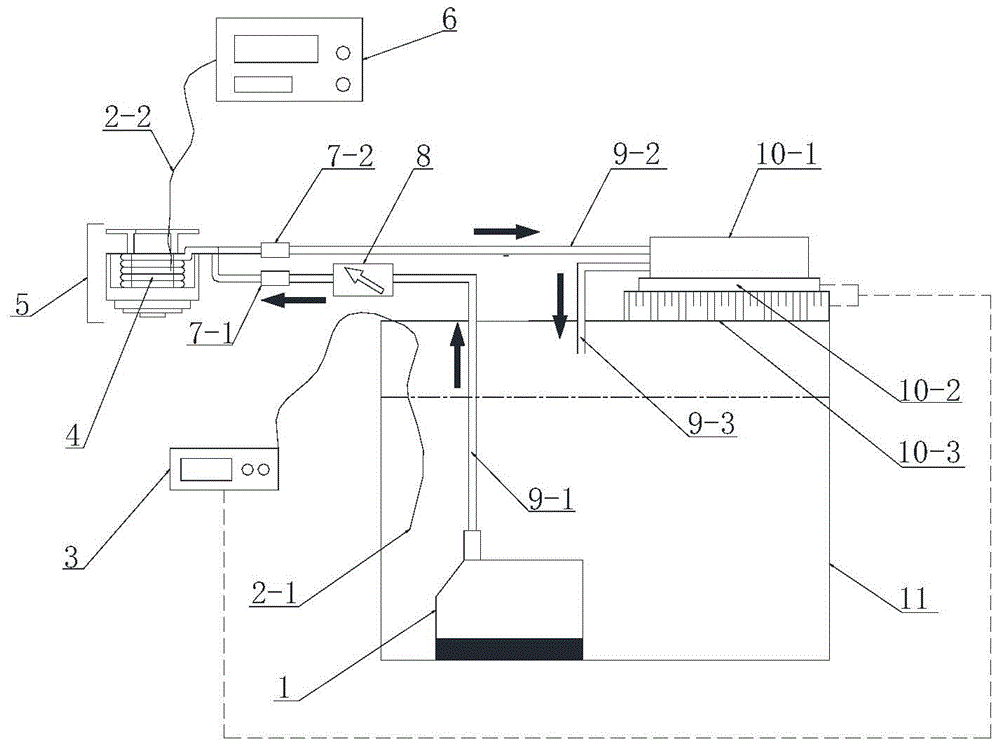

[0015] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings

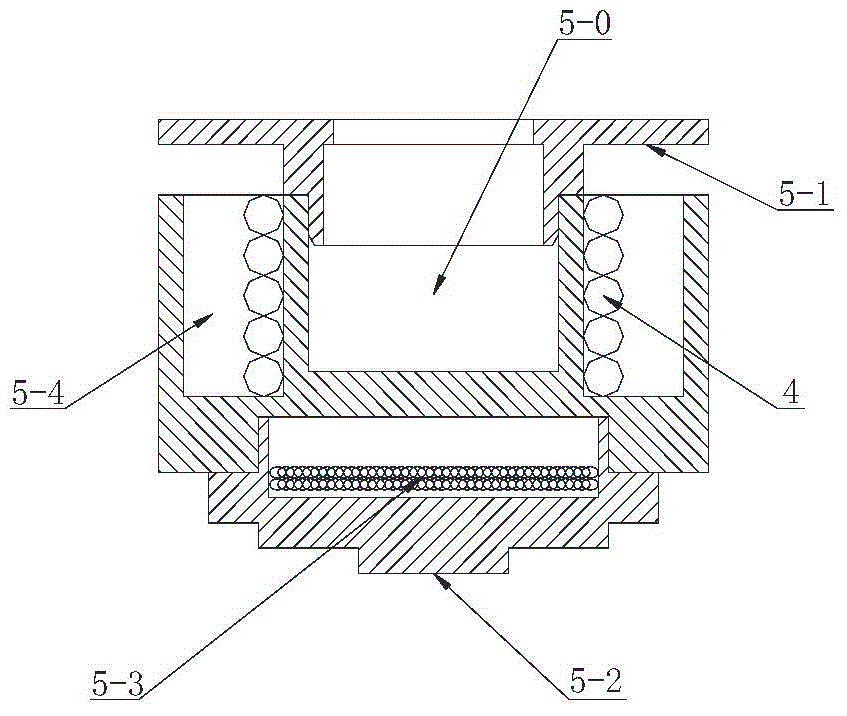

[0016] The precise temperature control system of the friction testing machine of the present invention includes a friction test piece container, a circulating water constant temperature device and a thyristor temperature controller, and is characterized in that the friction test piece container consists of an inner cavity 5-0, an outer cavity 5-4, and a base 5 -2 and the top cover 5-1, the friction test piece and the lubricating medium are set in the inner cavity 5-0; the circulating water constant temperature device is composed of a constant temperature water circulation pipeline and a constant temperature water temperature control mechanism, and the constant temperature water circulation pipeline The heat exchange pipe 4 is tightly set in the outer cavity 5-4 of the friction test piece container, and the constant temperature of the friction test piece container o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com