Oppositely-impacting quantitative atomization drug delivery apparatus

A drug delivery device and quantitative drug delivery technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of drug solution residue at the connection, drug concentration error, and influence on experiments, so as to prevent settlement, reduce settlement, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

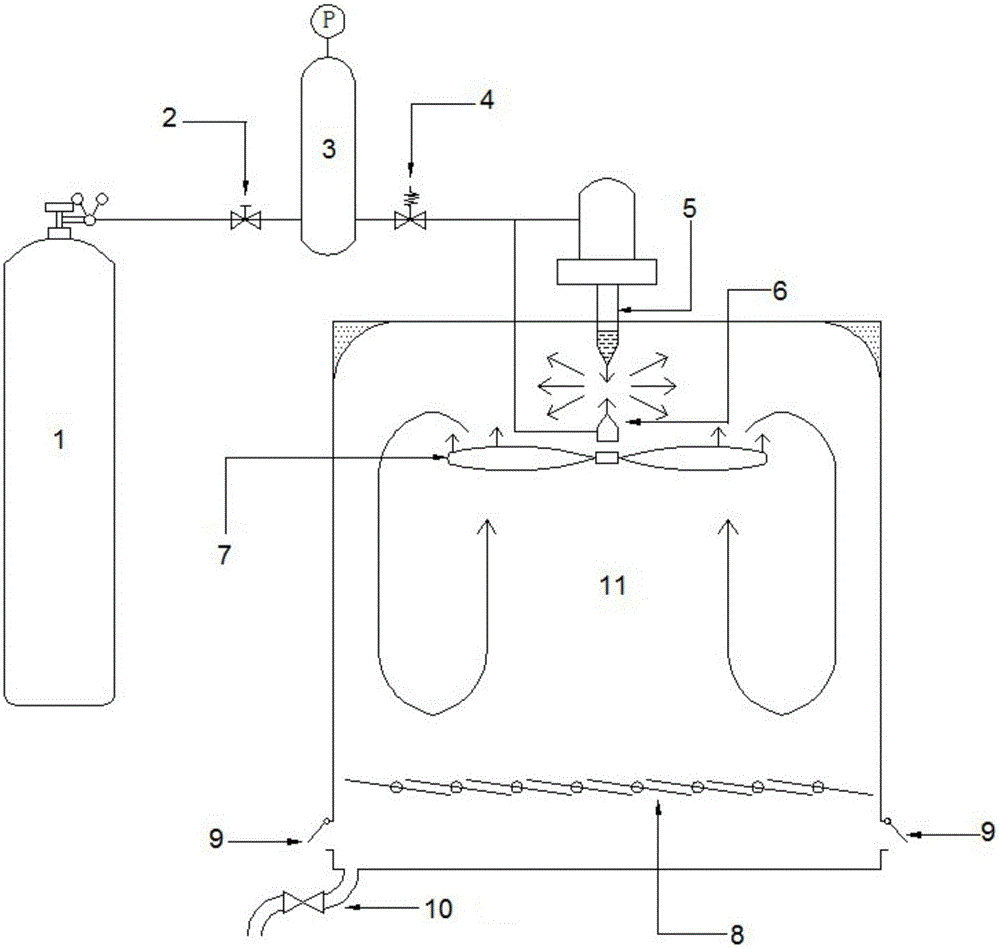

[0030] A hedging type quantitative atomization drug delivery device, its structure is as follows: figure 1 As shown, it includes: a high-pressure gas generating component, a quantitative drug delivery tube 5: the upper part is connected to the high-pressure gas generating component, and the bottom nozzle is provided with injection micro-holes, and the gas nozzle component 6 located in the poisoning cabinet 11 is connected to the high-pressure gas generating component, Set opposite to the nozzle of the dosing pipe 5, the top is provided with spray microholes, the low-speed fan 7 located in the poisoning cabinet 11, the dosing pipe 5 and the gas nozzle assembly 6 are provided with one or more spray microholes The liquid medicine ejected from the quantitative dosing tube 5 collides with the high-speed gas ejected from the gas nozzle assembly 6 to rapidly atomize the liquid medicine, and is evenly distributed in the poisoning cabinet under the agitation of the low-speed fan 7 . In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com