Miniature broadband helical antenna

A helical antenna and broadband technology, which is applied in the field of miniaturized broadband helical antennas, can solve the problems of complex antenna structure and difficult processing, and achieve the effects of flexible array formation, good circular polarization characteristics, and easy processing and realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

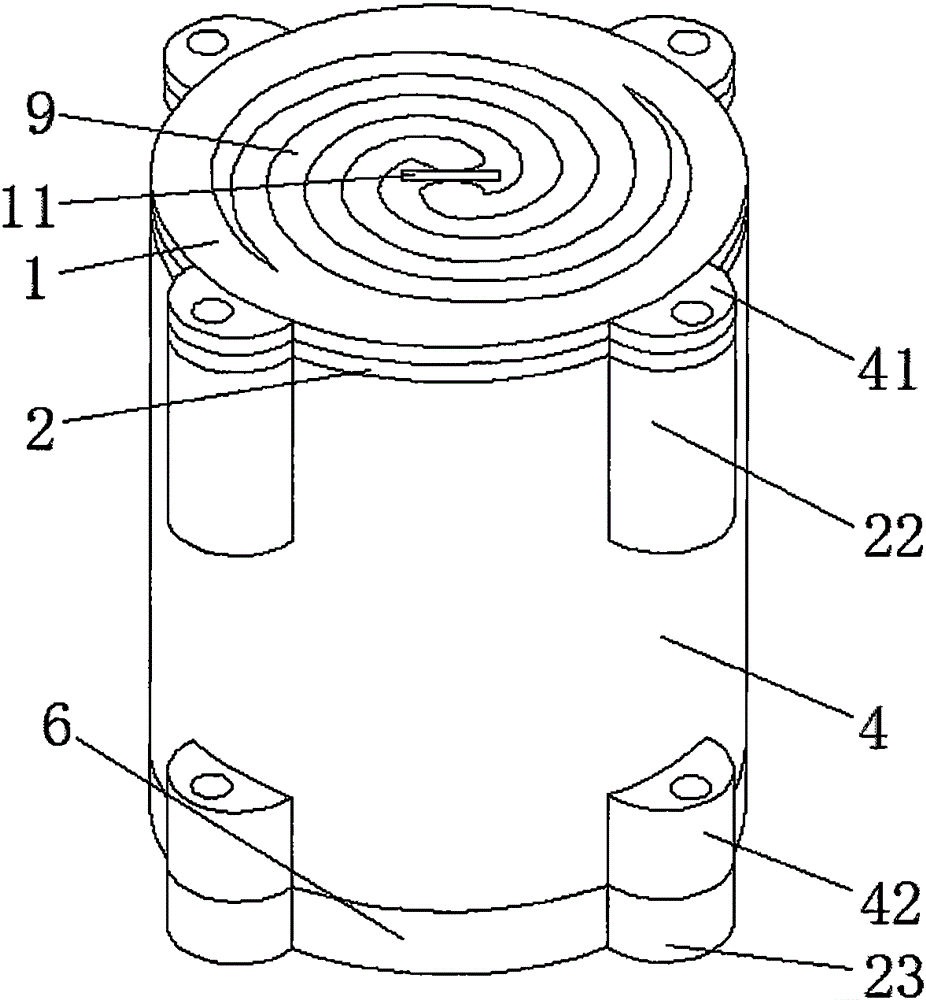

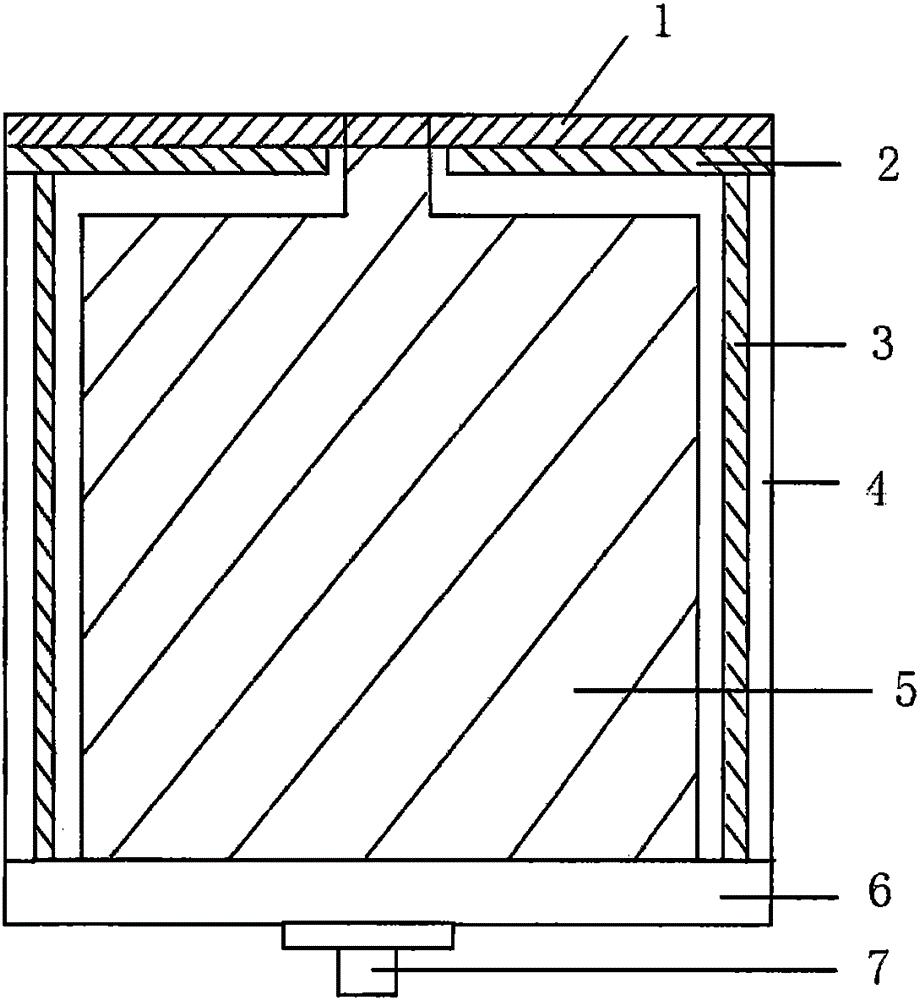

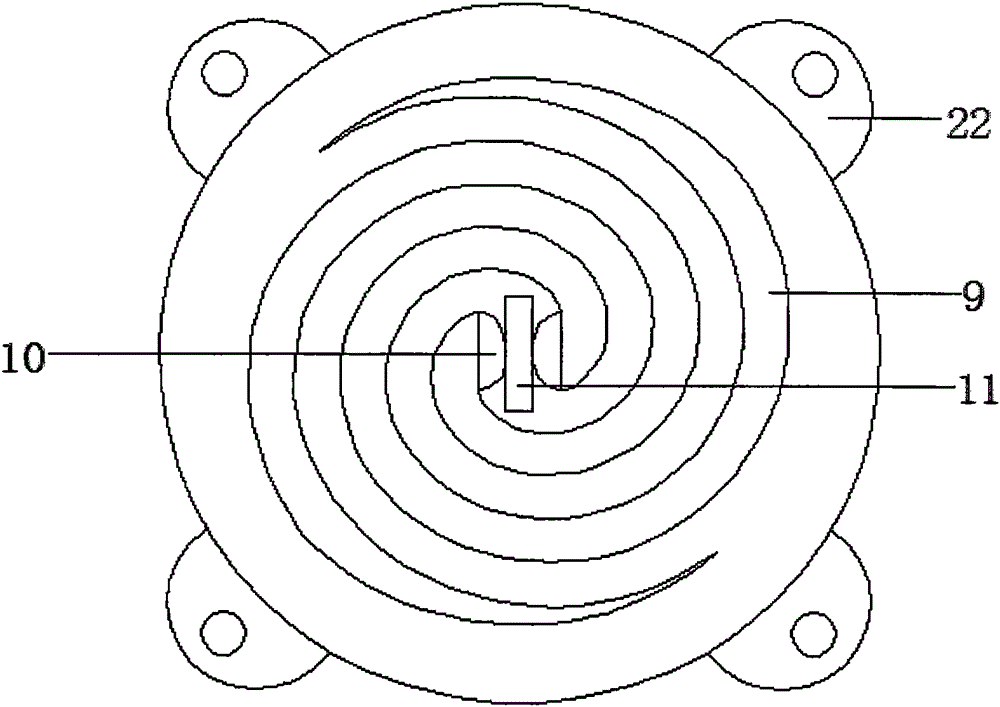

Embodiment 1

[0027] see Figure 1-9 , a miniaturized broadband helical antenna, which includes a metal cavity 4 with a hollow tubular structure as a whole, a first wave-absorbing material layer 3 is arranged on the inner wall of the metal cavity 4, and a feeding balun 5 is arranged inside it. An antenna layer 1 is fixed on the upper end surface of the metal cavity 4, and a metal back cover 6 is fixed on the lower end surface thereof. The bottom of the antenna layer 1 is provided with a second wave-absorbing material layer 2, and the feeding balun 5 The feeding slot 11 extending upwards from the top is in contact with the planar helical antenna 9, the bottom is provided with a feeding connector 7, and the other end of the feeding connector 7 extends out of a metal back cover 6, and the antenna layer 1 is entirely made of dielectric The material is processed and manufactured, and a planar helical antenna 9 is arranged inside it, and the described feeding slot 11 is located in the middle of t...

Embodiment 2

[0032] see Figure 1-6 , in this embodiment, the wall thickness of the metal cavity 4 described in Embodiment 1 is 1 mm, the diameter is 25 mm, the radius of the first connecting boss 41 and the second connecting boss 42 is 2.5 mm, and the antenna The whole layer 1 is made of dielectric material. The dielectric material adopts a dielectric material with a relative permittivity of 2.2 and a thickness of 0.787. The thickness of the second absorbing material layer 2 is 0.6mm; the feeding balun 5 adopts a relative permittivity 2.2 It is made of dielectric material with a thickness of 0.787. The feed balun 5 adopts an exponential gradient line microstrip structure. The feed balun 5 is connected to the feed connector 7 with a characteristic impedance of 50 ohms to realize the transition from unbalanced feed to balanced In the transition of feeding, at the balanced end, the widths of the exponentially changing structure 17 and the exponentially changing microstrip structure 18 are bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com