Self-calibrating pressure sensor system with pressure sensor and reference sensor that share common sealed chamber

A pressure sensor and reference sensor technology, which is applied in elastic deformation meter fluid pressure measurement, fluid pressure measurement, TV system components, etc., can solve the problems of adding reference sensors, increasing manufacturing costs, and reducing drift compensation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Exemplary embodiments are now described. Other embodiments may additionally or alternatively be used. Details that may be obvious or unnecessary may be omitted to save space or for more effective presentation. Some embodiments may be practiced with additional components or steps and / or without all of the described components or steps.

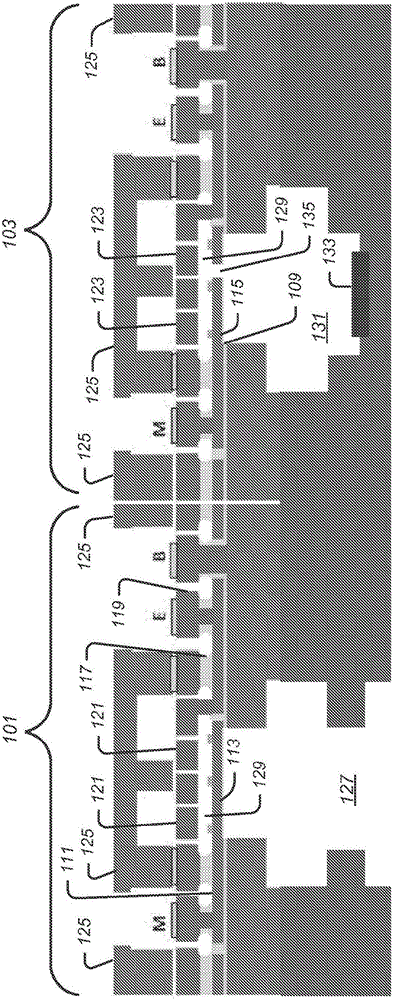

[0032] figure 1 An example is shown of a pressure sensor 101 and a matching reference sensor 103 that can all be fabricated using microelectromechanical systems (MEMS) deposition, patterning and etching techniques at the same time. More specifically, each of the corresponding components of the pressure sensor 101 and the matched reference sensor 103 may be fabricated layer by layer at the same time. Each layer may be deposited and / or grown, and may be made of any material such as silicon, silicon dioxide, silicon nitride, or metal. After deposition, each layer can be patterned to identify portions of the layer to be removed, and an e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com