A kind of acetic acid mixer structure

A mixer and acetic acid technology, applied in mixers, chemical instruments and methods, dissolution, etc., can solve problems such as incomplete reaction, deviation of predetermined value, and influence on normal process, so as to achieve sufficient mixing effect and small mixing ratio error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

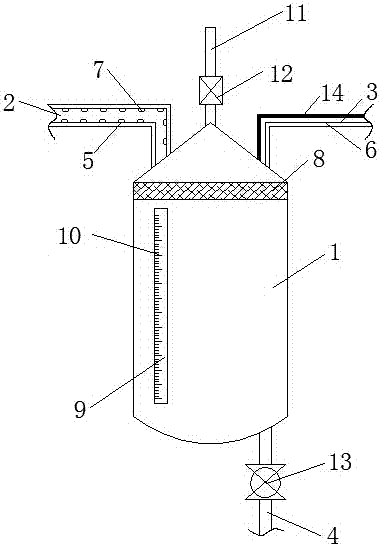

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, the embodiment of the present invention comprises mixer 1, and the upper end of mixer 1 is provided with the first feed pipeline 2 that is used for the 80% acetic acid feed of concentration and the second feed pipeline 2 that is used for the glacial acetic acid feed of 99% concentration. A material pipeline 3; the lower end is provided with an acetic acid discharge pipeline 4, and a ball valve 13 is provided on the acetic acid discharge pipeline 4. The outer side of the first feed pipe 2 is provided with a heat insulation layer 5, and the outer side of the second feed pipe 3 is provided with an insulating layer 6 which keeps the temperature of the material in the second feed pipe 3 above 16°C. The insulation layer 6 has a certain heating function to deal with the situation that the ambient temperature is too low, and the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com