An organic waste washing device and method

A technology of organic waste and washing equipment, which is applied in the field of organic waste washing and organic waste washing equipment, and can solve problems such as easy breeding of bacteria, difficulty in sorting or anaerobic treatment, and generation of landfill leachate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

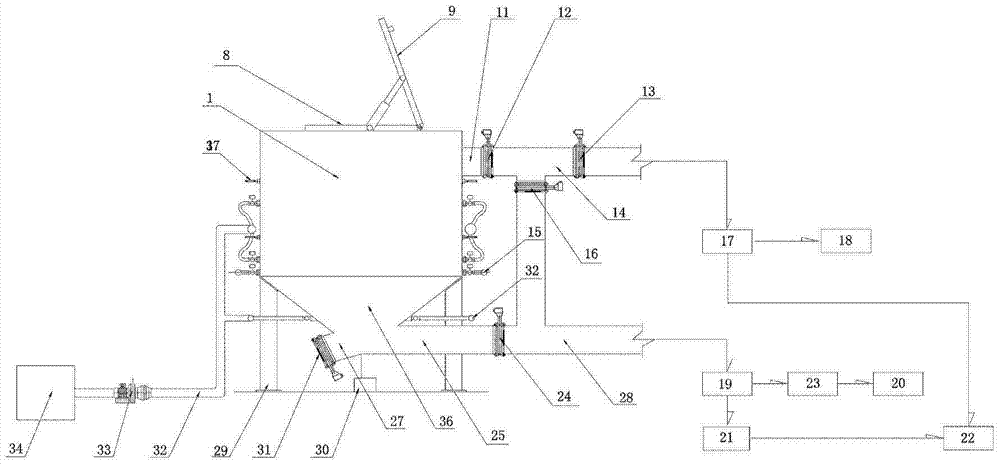

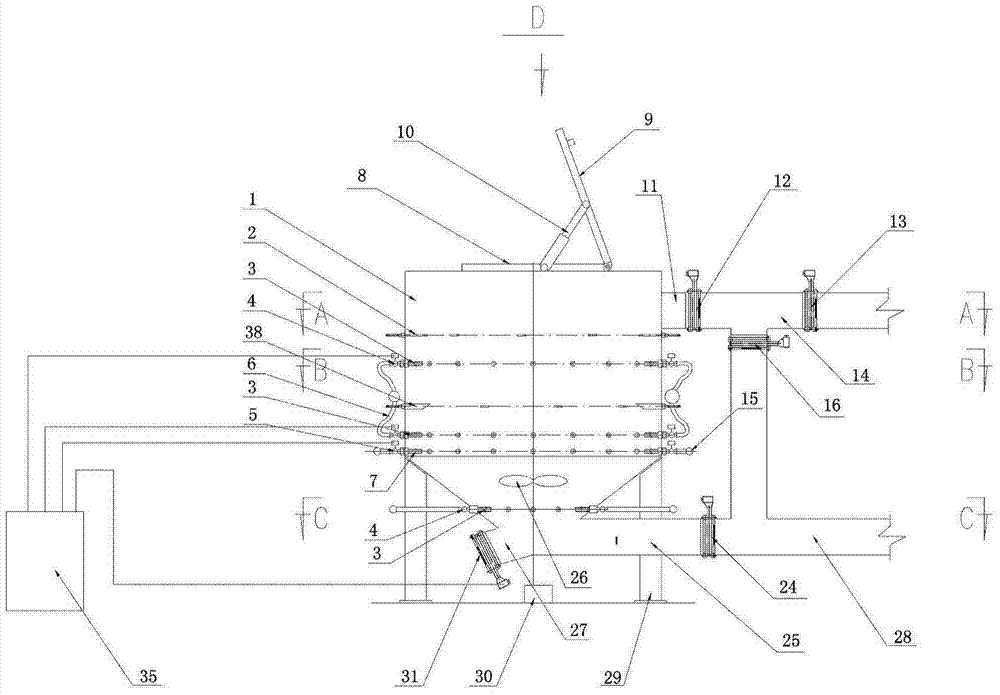

[0140] The organic waste washing device provided by the present invention is used to wash municipal solid waste.

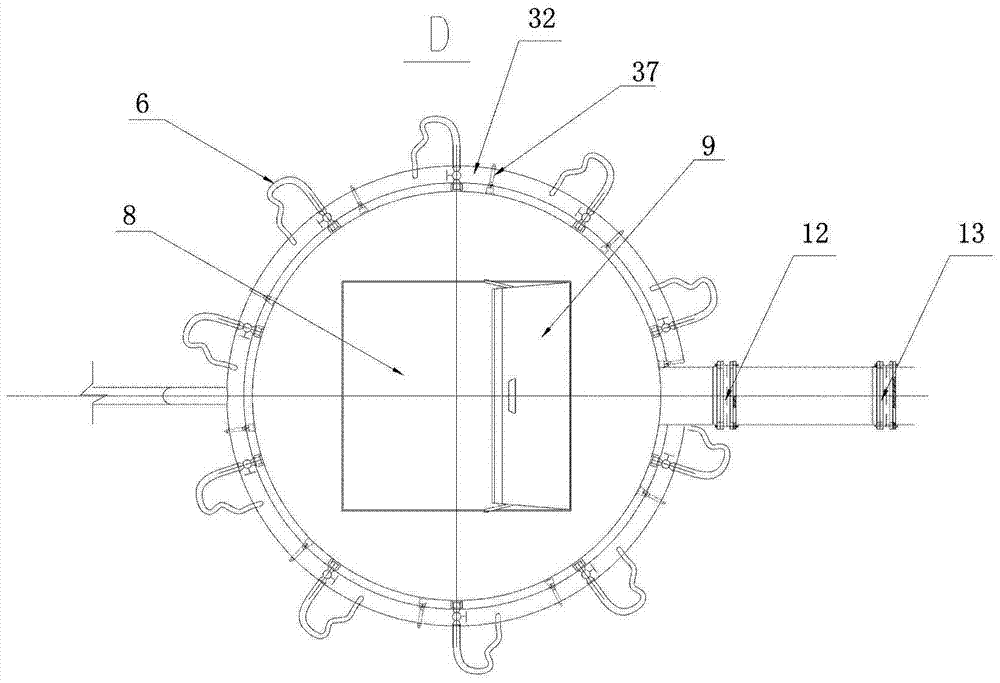

[0141] The organic waste washing device, the tank 1 has a diameter of 3.6 meters and a height of 4.7 meters, and is supported by four uprights 29 .

[0142] The top of the tank body 1 is provided with a feeding port 8 of 2 meters x 2 meters, and a sealing cover 9 is arranged on the feeding port 8. The sealing cover 9 is opened and closed by an actuating cylinder 10, and the second actuating cylinder 10 is pneumatic, which is a well-known product;

[0143] The bottom of the tank body 1 is a cone-shaped body 36, one side of the cone-shaped body 36 is the DN500 lower discharge port 25, and the other side of the cone-shaped body 36 is the DN600 inspection port 27; the inspection port 27 is installed with an automatic gate valve D31; There is a propeller 26 in the body 36; the propeller 26 is driven by the reducer 30; the side wall of the cone body 36 is 3.3 meters awa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com