Four-head surfacing machine

A technology of surfacing welding machine and welding torch, which is applied in the field of surfacing welding machines, which can solve the problems of low surfacing welding efficiency, damage, and unstable structure of the whole machine, and achieve the effect of improving efficiency and high-efficiency surfacing welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

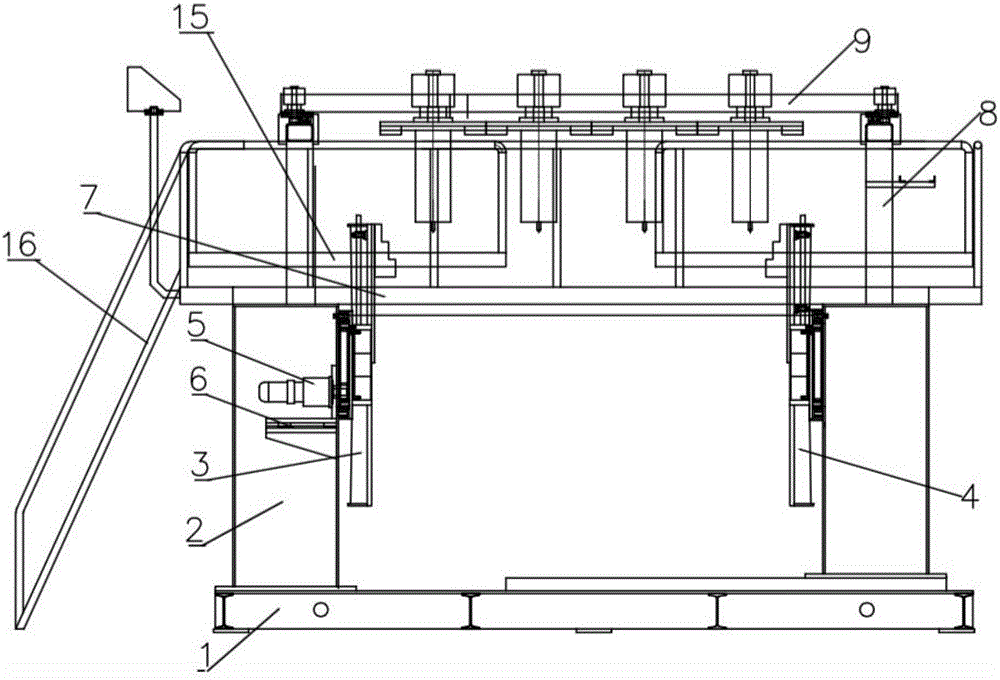

[0018] combine Figure 1-3 , the present invention proposes a four-head surfacing welding machine, including a machine base 1, a fixing seat 2 located on the machine base 1, and a first chuck 3 and a second chuck 4 are arranged oppositely on the fixing base 2 , the first chuck 3 is connected to the output end of the motor 5, the fixed seat 2 is provided with a first chute 6, the motor 5 is installed on the first chute 6, and the motor 5 is placed on the The first chute 6 is far away from or close to the first chuck 3, when the motor 5 moves away from the first chuck 3 on the first chute 6, the output end of the motor 5 is separated from the chuck, and the chuck stops Rotation is easy to disassemble, which solves the problem that the chuck is not easy to disassemble due to its heavy weight.

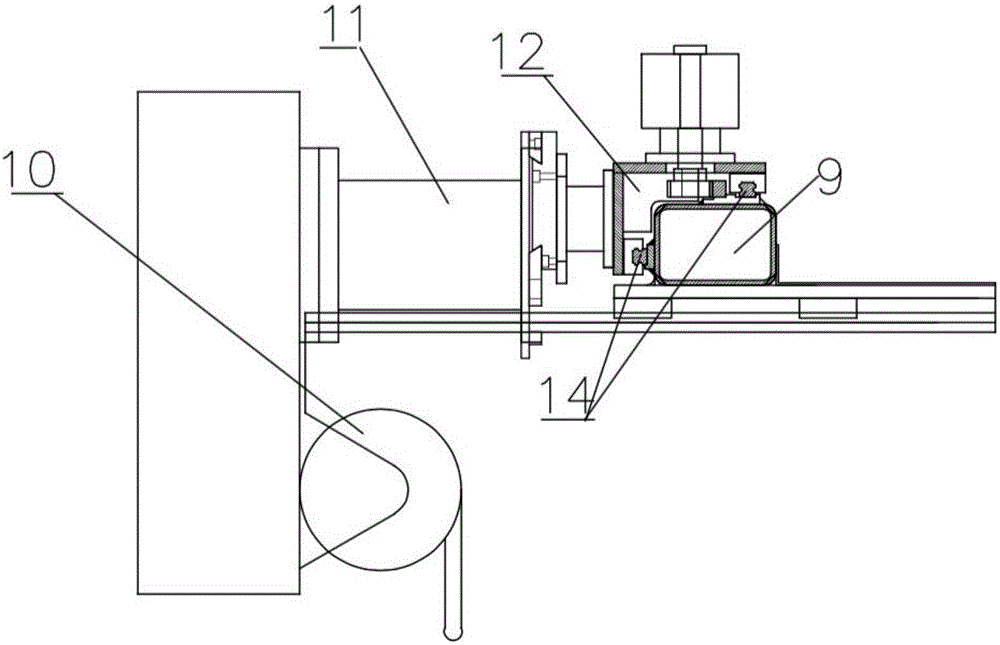

[0019] The fixed seat 2 is provided with a fixed platform 7, the upper part of the fixed platform 7 is provided with a bracket 8, and the bracket 8 is provided with a slide rail 9, and fo...

Embodiment 2

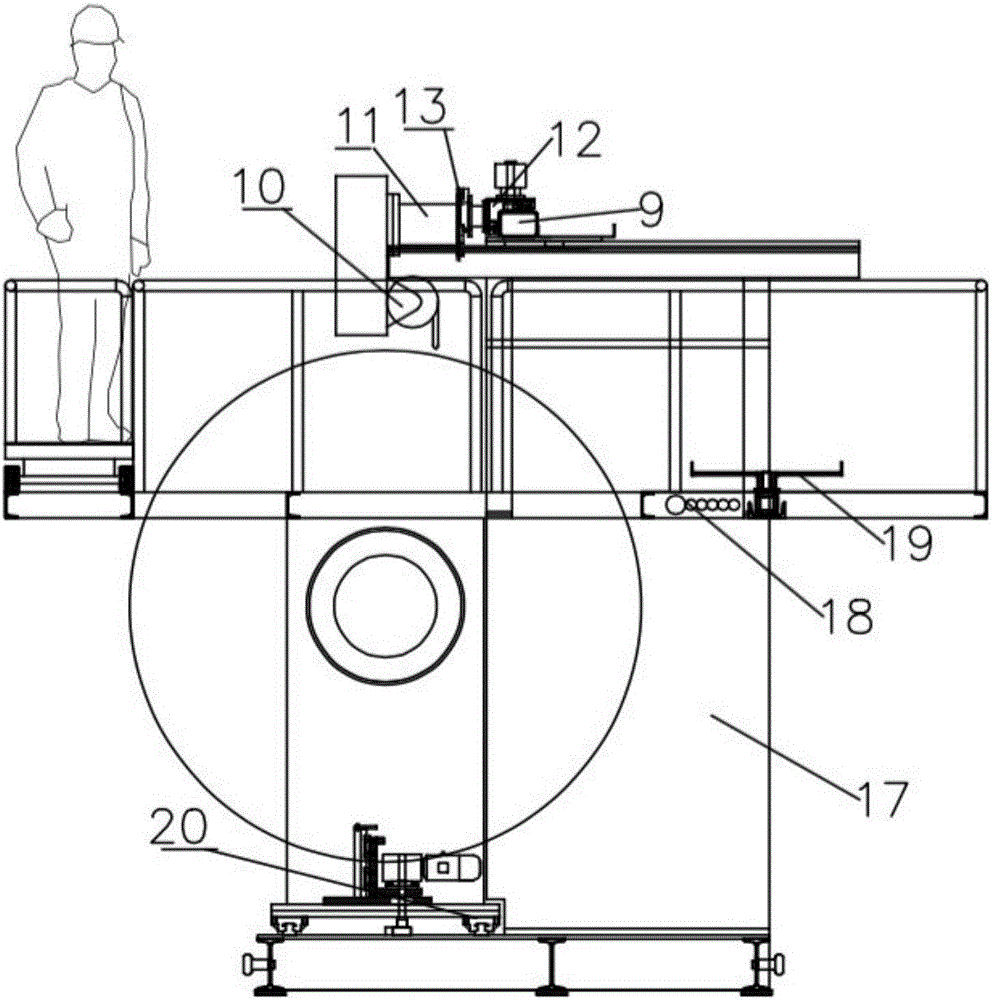

[0021] In this embodiment, on the basis of Embodiment 1, a welding machine room 17 is provided at the lower part of the fixed platform 7, and the welding machine room 17 is used to place a power supply or a spare welding machine. At the same time, the fixed platform 7 on the upper part of the welding machine room 17 Inside is inserted with some steel pipes 18 for routing, and the lines in the welding machine room 17 are connected to the upper welding device by the steel pipes 18, effectively placing the lines around the fixed platform 7, which affects the work.

[0022] In addition, a tray 19 is provided on the side of the fixed platform 7, and the tray 19 is movably connected to the side of the fixed platform 7 through a steel channel. The tray 19 can slide on the side of the fixed platform 7, and the welding wire is placed on the tray 19. .

Embodiment 3

[0024] On the basis of Embodiment 1 or 2, an additional movable platform 15 is provided on the fixed platform 7, and the movable platform 15 includes a stand plate positioned on the fixed platform 7, and handrails are provided on both sides of the stand plate, so One side of the movable platform 15 is provided with a ladder 16, the movable platform 15 is a frame structure, placed on the fixed platform 7, the position can be adjusted according to the needs for the operator to stand, it can be removed when not in use, it is very convenient to use, and it can also be used For carrying heavier objects, the staff stands on the fixed platform 7 to promote the activities and the platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com