Automatic assembly machine for expansion bolts

An automatic assembly machine and expansion bolt technology, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as complex positioning, failure of expansion sleeve rotation and fixation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

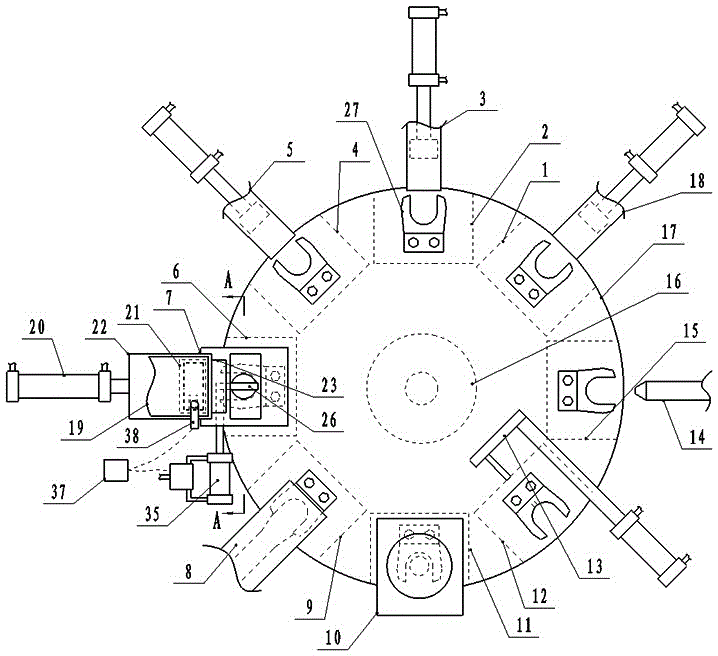

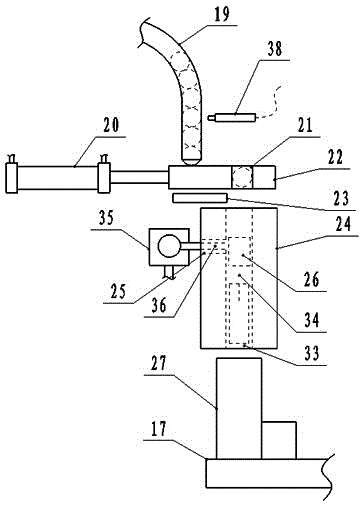

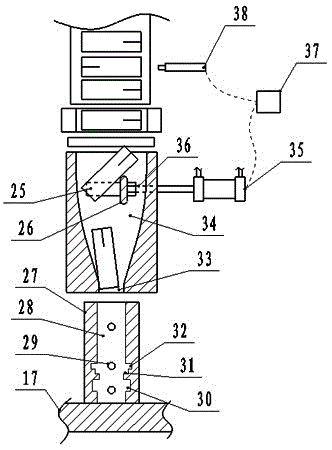

[0011] Example: such as figure 1 , figure 2 and image 3 As shown, the expansion bolt automatic assembly machine is equipped with a nut positioning station 1, a spring pad positioning station 2, a flat pad positioning station 4, an expansion sleeve positioning station 6, and a screw positioning station 9 on its indexing plate 17. , screw tightening station 11 and finished product demoulding station 12, each station is evenly distributed on the edge of the indexing plate 17, a fixed mold 27 with the same structure is installed on each station, and an expansion sleeve is designed on the fixed mold 27 Fixing groove 28, nut fixing groove 30, spring pad fixing groove 31 and flat pad fixing groove 32 have drop-off holes 29 on the back side of the fixed mold 27, and a nut feeding device 18 is installed on the outside of the nut positioning station 1, and is positioned on the spring pad. A spring pad feeding device 3 is installed outside station 2, a flat pad input device 5 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com