A UHP Abrasive Jet Downhole Cutting Tool

An abrasive jet, cutting machine technology, applied in abrasive jet machine tools, abrasives, used abrasive processing devices, etc., can solve the problems of easy damage to cutting knives and marine environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

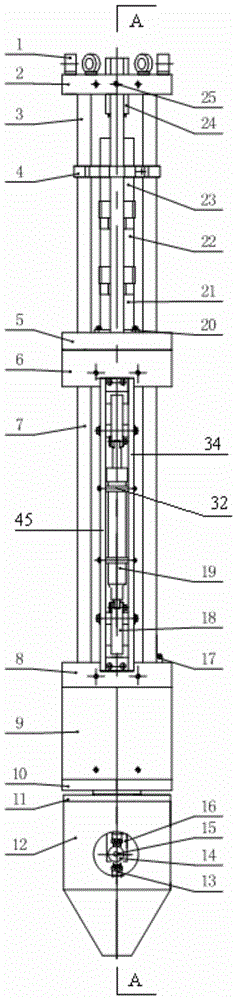

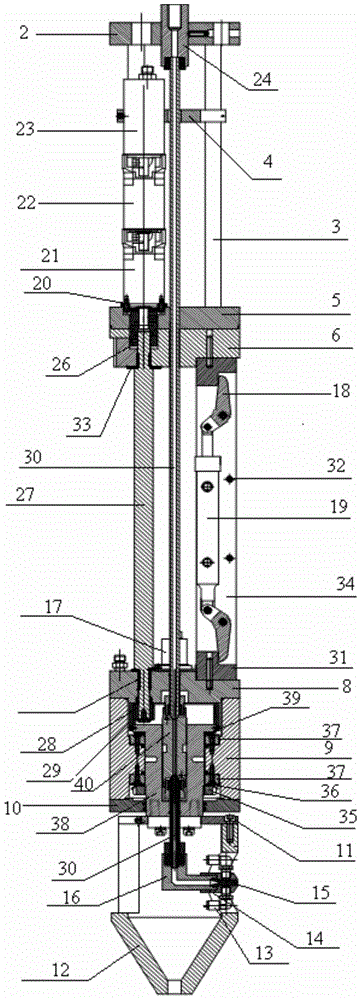

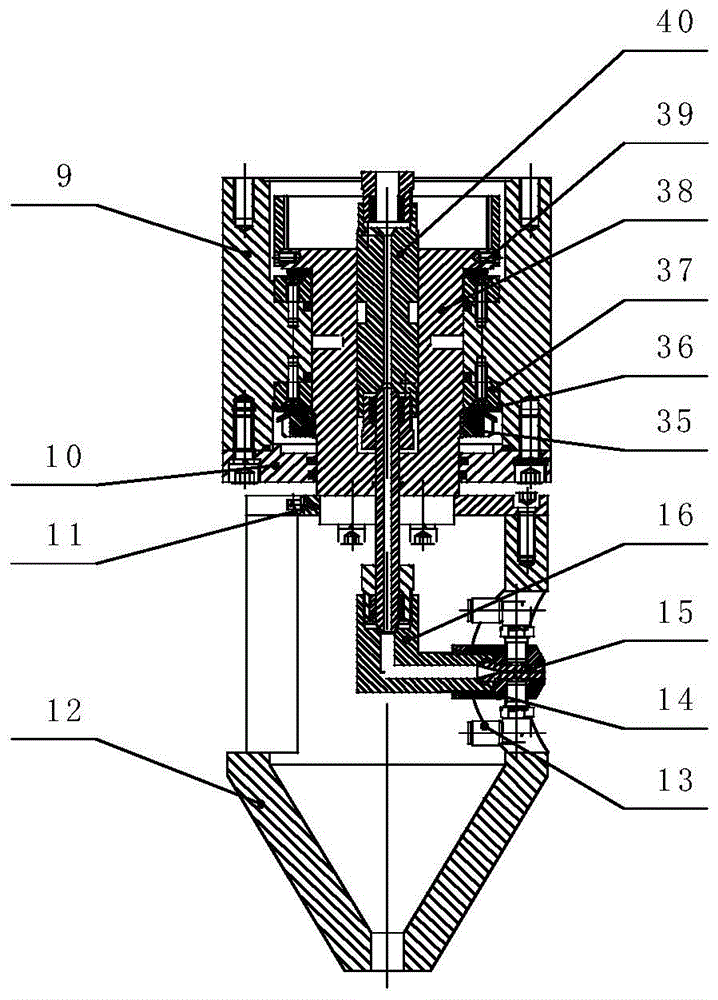

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] The ultra-high pressure abrasive jet downhole cutting tool of the present invention includes an external support module, a hydraulic drive module, a centering module, an ultra-high pressure rotary cutting head module and a cutting speed monitoring module connected to each other.

[0030] The external support module includes a first flange 2 with a high-pressure pipeline connector 24 in the middle, lifting lugs 1 can be evenly arranged on the upper part of the first flange 2, and the side wall of the first flange 2 Flat-head screws 25 for fixing high-pressure pipeline joints 24 are provided, and the lower part of the first flange 2 is connected with a second flange 5 through four uniformly vertically arranged upper support columns 3, and the upper support columns 3 Perpendicular to between the first flange 2 and the second flange 5, the second flange 5 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com