Stitch skipping prevention device for textile use

An anti-jump, textile technology, applied in textiles and papermaking, transportation and packaging, transportation of filamentous materials, etc., can solve the problems of insignificant guiding effect and unreasonable structural design, and achieve reasonable structure, prevention of breakage, and accurate guidance. and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

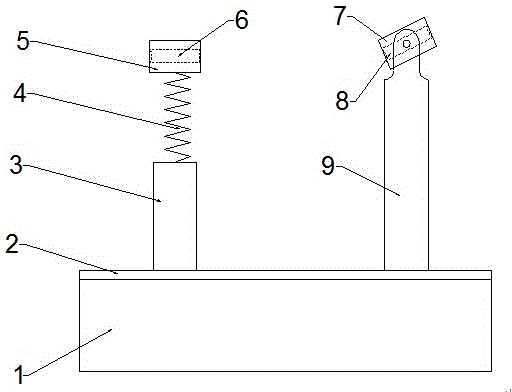

[0014] Such as figure 1 As shown, the present invention discloses an anti-jumping device for textiles, which includes a base 1, a traction device and a guide device arranged side by side on the upper end of the base 1 .

[0015] A pair of guide rails 2 are arranged in parallel on the base 1, and the two ends of the pair of guide rails 2 are embedded to cooperate with the traction device and the guide device.

[0016] The traction device includes a base A3, a tension spring 4 and a threader A5 arranged upwards on the base 1 in turn, and a through hole A6 for the yarn to pass is arranged on the threader A5, and the two ends of the through hole A6 are arc-shaped; The guide device includes a base B9 and a threader B7 which are arranged upwards on the base 1 in turn. A through hole B8 for the yarn to pass is arranged on the threader B7. The two ends of the through hole B8 are arc-shaped. At the same time, the threader B7 B7 is hinged on the upper end of base B9.

[0017] When usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com