Buffering and energy dissipation device for slope protection

An energy dissipation device and slope protection technology, applied in excavation, construction, infrastructure engineering and other directions, can solve the problems of increased local force, damage, and reduced system protection ability of the system, and achieve the effect of easy disassembly and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

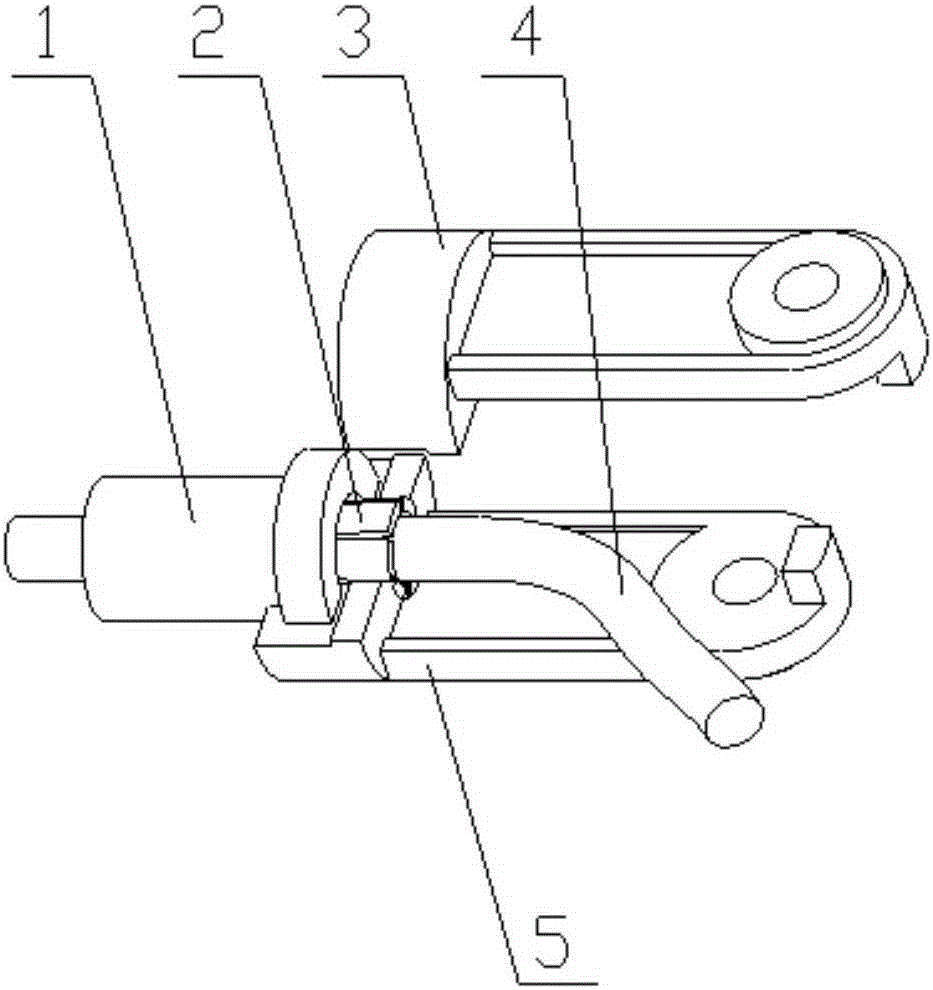

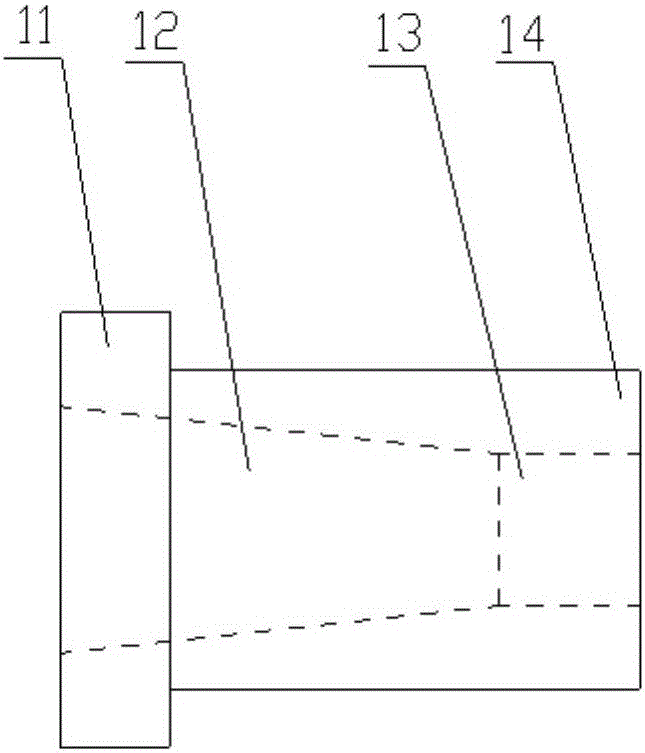

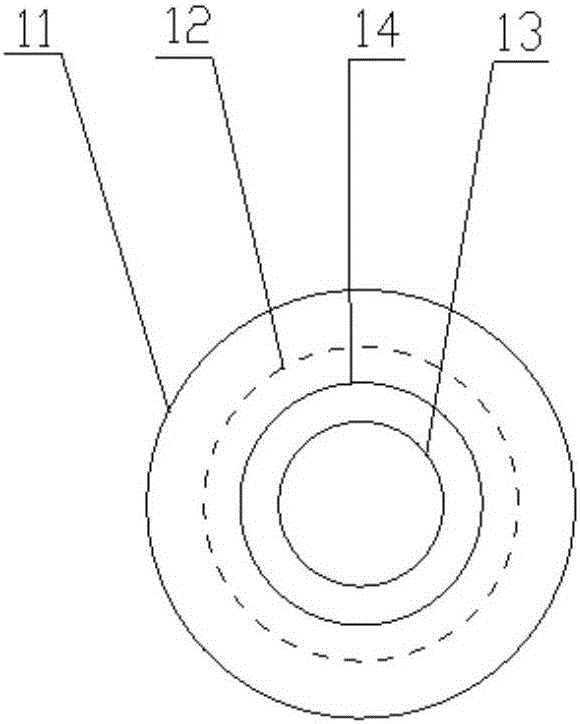

[0022] figure 1 shows the main structure of the present invention, Figure 2 to Figure 5 is the specific structure of casing 1, Figure 6 and Figure 7 is the specific structure of chuck 2, Figure 8 to Figure 10 The specific structures of the clamp and the upper clamp 3 are shown.

[0023] The structure of the present invention is as follows: it is mainly composed of chuck 2, casing 1 for accommodating chuck 2, and a clamp. One end of the internal through hole of casing 1 is large and the other end is small. The pipe body 14 makes the collet 2 can only be put in from the casing head 11. The collet 2 is a conical cylinder with shrinkage, and the size of its internal channel is equivalent to the size of the rope 4. The clamp is composed of an upper clamp 3 and a lower clamp 5. The structure and size of the upper fixture 3 and the lower fixture 5 are exactly the same. The upper fixture 3 is mainly composed of a strip plate 32 and a clamping part 33. One end of the strip plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com