A special universal three-claw top drill for top tightening of drilling rig, boom, rock drill

A technology for rock drills and drilling rigs, which is applied in the field of universal three-claw top drilling for drilling rigs, booms, and rock drills. It can solve the problems of uneven drilling sections, low efficiency, and inability to position, so as to eliminate eccentric force and improve rigidity. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

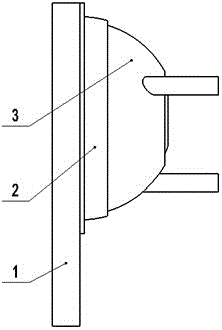

[0020] A special universal three-claw top drill for top-tightening drilling rig boom rock drill, consisting of a base 1, a fixer 2, and a positioner 3, wherein the base 1 is installed on the mechanical arm at the end of the drilling rig boom rock drill, and its center The position is hollow, which can be extended by the drill bit of the rock drill, and a semicircular locator 3 is buckled on the base 1, and the locator 3 is fixed on the base 1 by the fixer 2. The drill bit of the drilling rig passes through the center of the ball of the universal three-claw top drill, so that the tolerance of the three-claw top drill to the drill bit is realized.

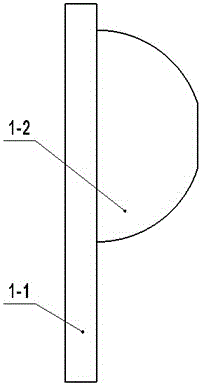

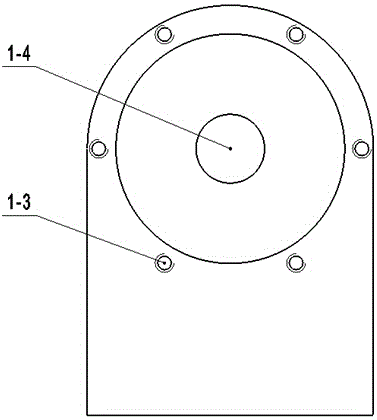

[0021] The base 1 is composed of a fixed seat 1-1, a support hemisphere 1-2, a base threaded hole 1-3, and a base drilling hole 1-4. Among them, the fixed seat 1-1 is mainly used to realize the connection between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com