Soft measurement method for overflow particle size of hydrocyclone

A hydrocyclone and soft measurement technology, applied in instruments, special data processing applications, electrical digital data processing, etc., can solve problems such as troublesome, expensive particle size analyzers, and long testing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

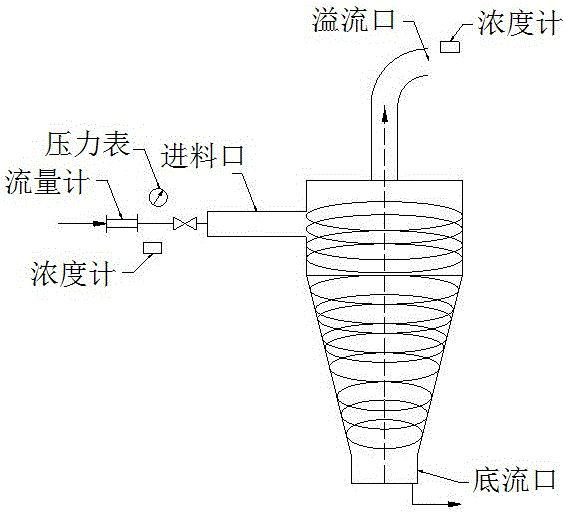

[0048] Such as figure 1 As shown, an embodiment of the present invention includes the following steps:

[0049] A. Separately collect the historical operation data of the ore concentration x i1 、Historical operating data of mine flow rate x i2 , historical operating data of working pressure at feed inlet x i3 , overflow concentration historical operating data x i4 , overflow granularity historical operating data y i , where i=1,2,...,n, n is the number of samples used to train the model;

[0050] B. Respectively for x ik (k=1,2,3,4) and y i After normalization, the processed values are with Get the sample set as in x ‾ i = x ‾ i 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com