System for automatically monitoring and controlling mechanical agitating fuel oil and water mixing device

A technology of mechanical stirring and control system, which is applied in the direction of combustion method, liquid fuel supply/distribution, etc. It can solve the problems of uncontrollable water mixing ratio, low degree of automation, uneven dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be specifically described below with reference to the examples.

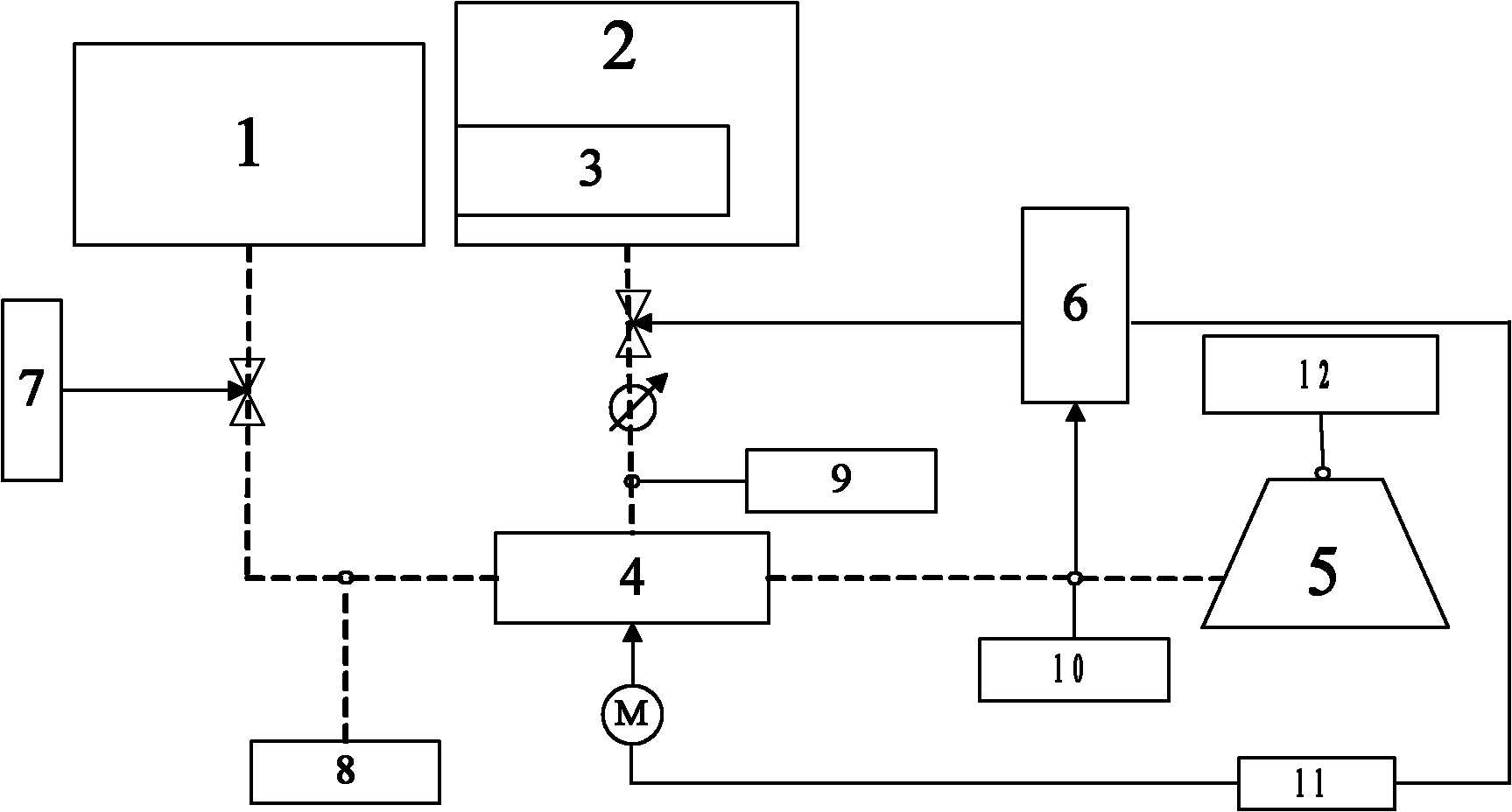

[0027] (1) The frequency control circuit of the fuel metering pump and the water metering pump at the inlet of the fuel water mixing device

[0028] Control task: By adjusting the frequency of the inlet fuel metering pump and water metering pump, the fuel oil mixed with water can meet the combustion requirements of the boiler;

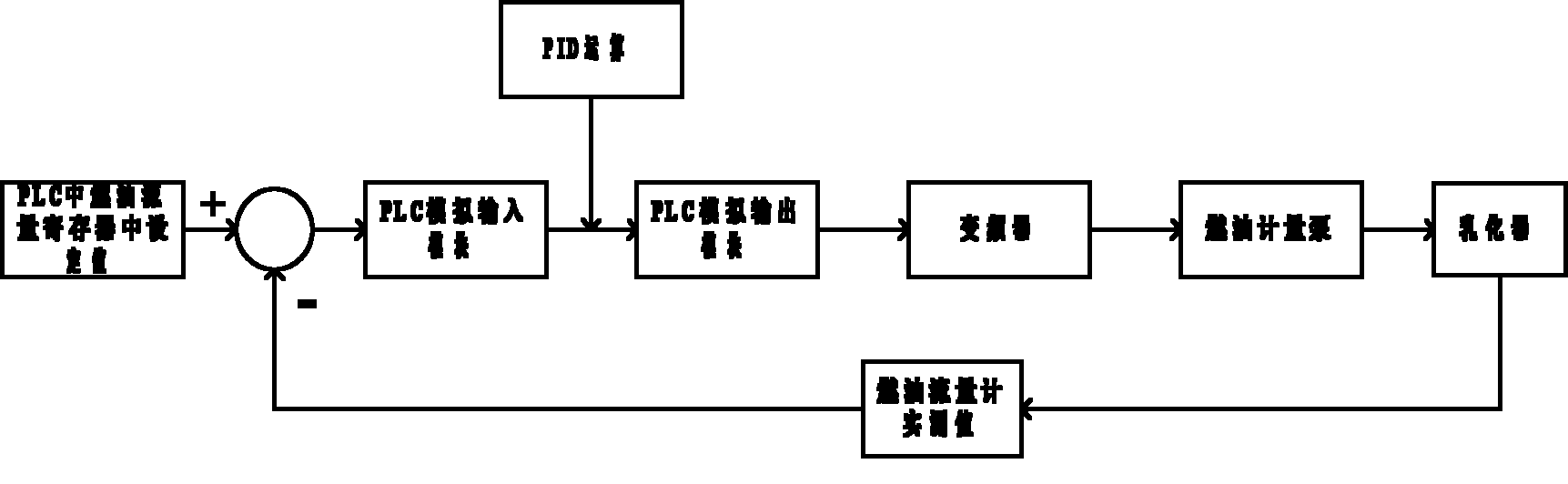

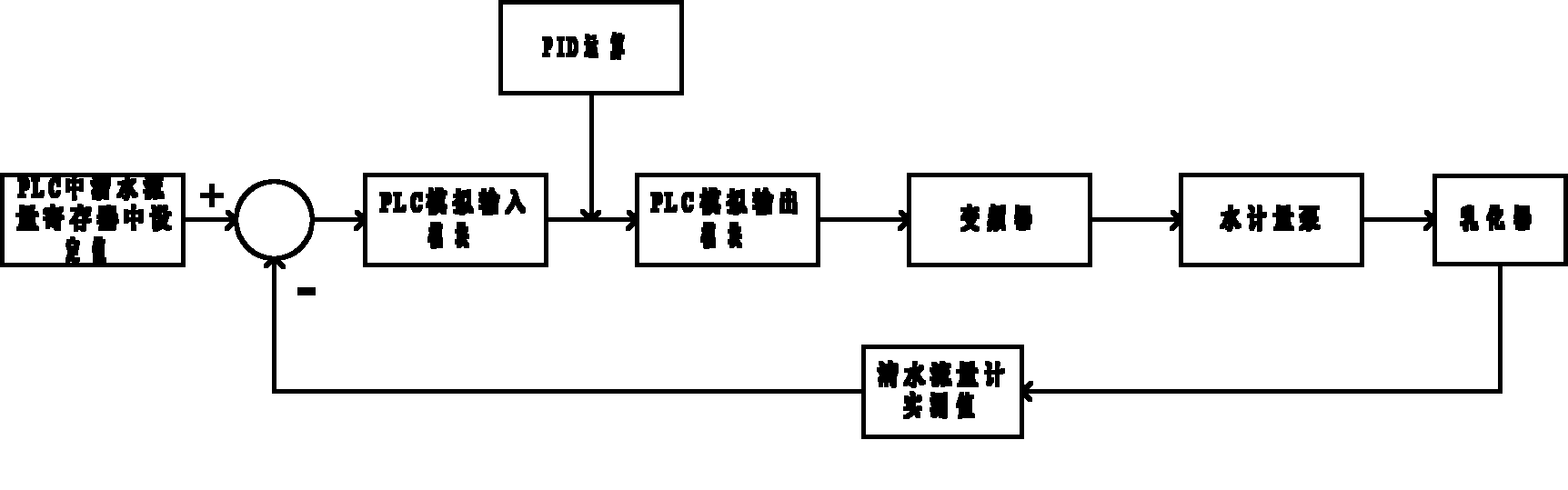

[0029] Control scheme: Inlet fuel metering pump frequency control loop, see figure 2 , the water metering pump frequency control loop, see image 3 . The clean water passes through the water metering pump, and the fuel oil is simultaneously added to the water mixing device through the fuel metering pump, that is, the oil delivery pump. The system first measures the flow of clean water and inlet fuel, converts it into a 4-20mA signal and sends it to the PLC analog input module. After PID (proportional, integral and derivative) calculation, the generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com