Wall-mount installation base

A mounting seat and mounting hole technology, applied in electrical components, electrical switches, circuits, etc., can solve the problems of large processing volume and complex structure, and achieve the effects of good manufacturability, simple structure, and safe and reliable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The detailed structure of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

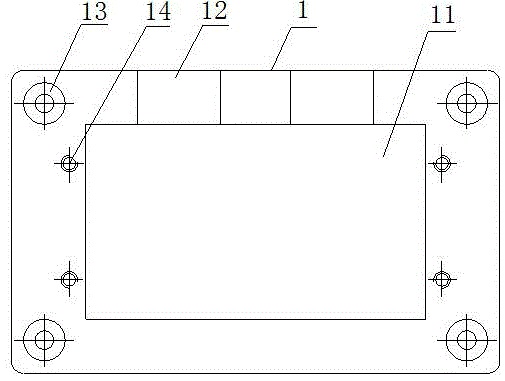

[0021] Such as figure 1 Shown: a wall plug mounting seat, including a seat body 1 and a switch body (not shown in the figure), the seat body 1 is installed on the outer surface of the shelter plate, and the middle part of the seat body 1 is equipped with a switch body A through hole 11 is provided; one side of the seat body 1 is provided with an outlet slot 12; the peripheral edge of the seat body 1 is provided with wall installation holes 13; two switch body installation holes 14 are respectively provided on both sides of the through hole 11. In this embodiment, the switch body is installed on the seat body 1, and the wires are routed from the outlet slot 12 of the seat body 1, and the seat body 1 is installed on the outer surface of the shelter plate. On the one hand, it saves time and effort, and it is very convenie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com