Hoisting device for outdoor assembled electric equipment

A technology for electrical equipment and hoisting devices, applied in the direction of switchgear, electrical components, etc., can solve problems such as poor hoisting stability, achieve stable hoisting, ensure stability, and facilitate disassembly and replacement of suspenders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below by means of specific embodiments:

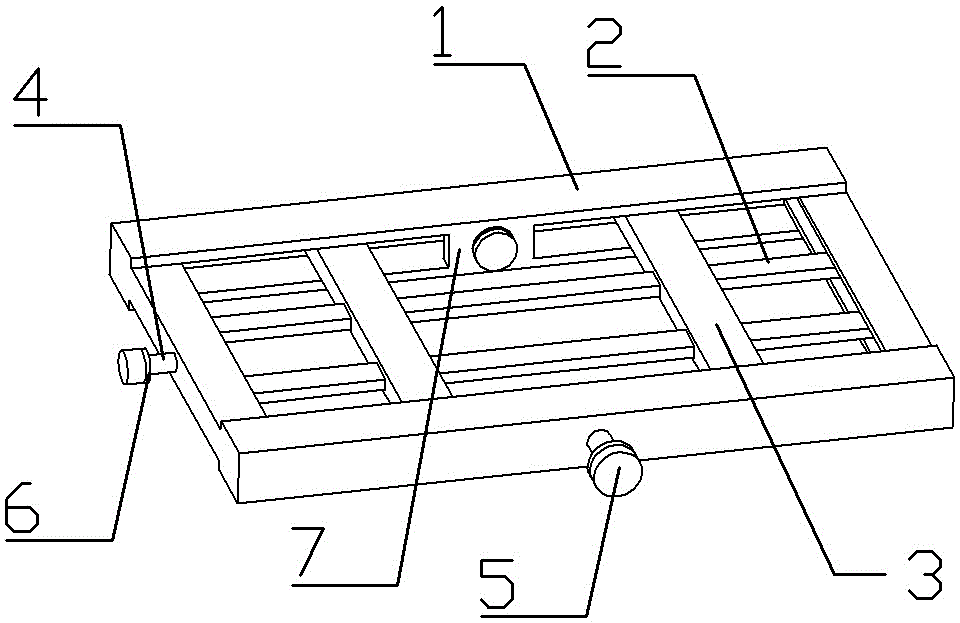

[0011] The reference signs in the accompanying drawings of the specification include: frame 1 , horizontal frame 2 , vertical frame 3 , rod portion 4 , limit plate 5 , spacer 6 , and reinforcing plate 7 .

[0012] as attached figure 1 As shown, the rectangular frame 1 is welded end to end by four channel steels in turn, and two horizontal frames 2 and two vertical frames 3 are respectively welded inside the frame 1, and the two horizontal frames 2 and two vertical frames 3 form the bottom frame structure.

[0013] The middle part of each side of the frame 1 is provided with a threaded through hole, and the four through holes are provided with horizontal suspenders perpendicular to the sides of the frame, so that the suspenders are evenly distributed around the frame. The boom includes a rod part 4 and a limit disc 5 which is threaded at both ends of the rod part. The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com