Ladle bottom and ladle

A technology of casting ladles and refractory ceramics, which is applied in the field of metallurgical ladles and can solve unsolved problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

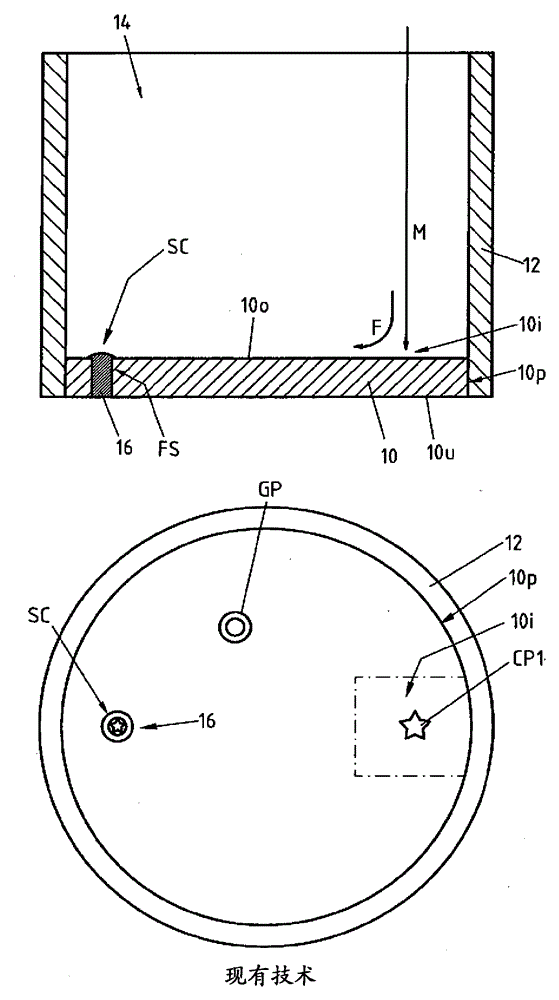

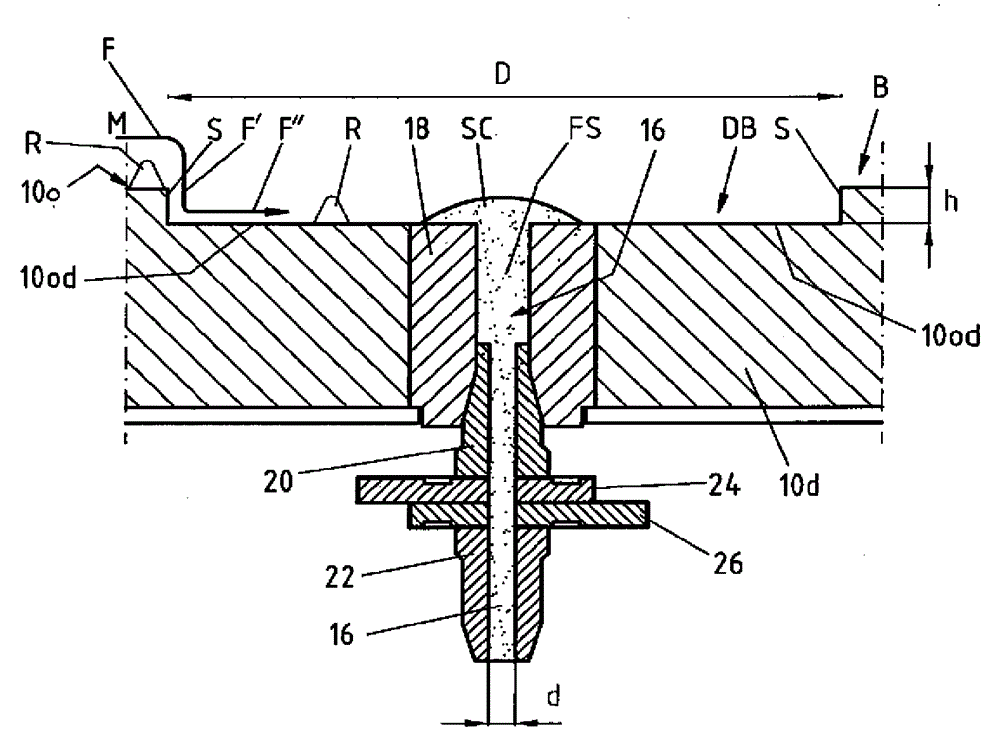

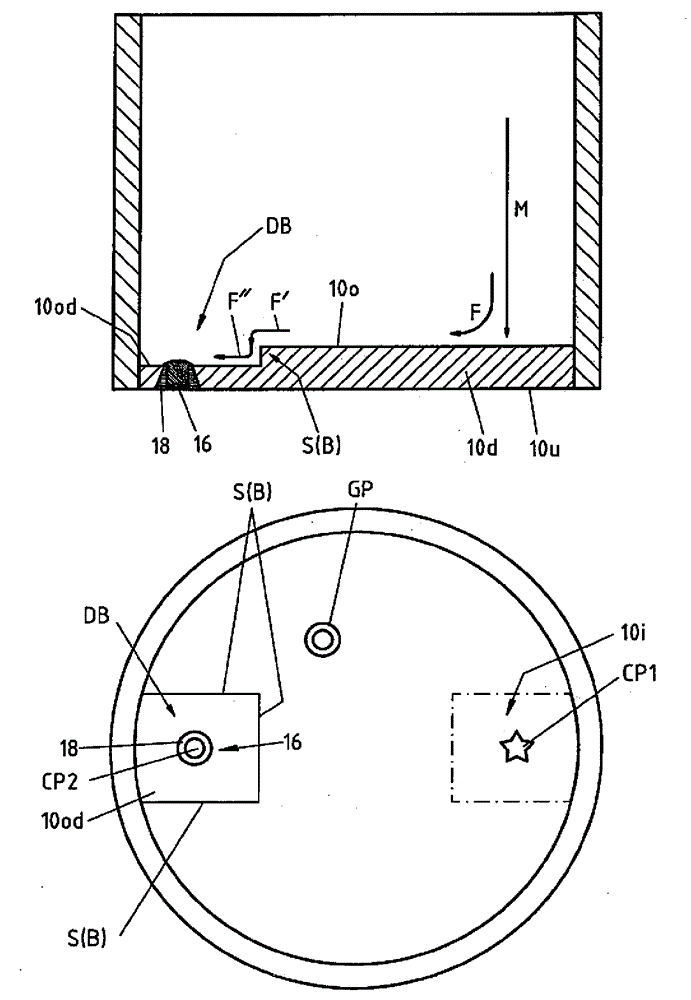

[0071] figure 1 The ladle has a circular horizontally extending bottom 10 with an upper horizontal surface 10o and a lower horizontal surface 10u. A generally cylindrical ladle wall 12 extends upwardly from the outer periphery 10 p of the ladle bottom 10 . The open upper end of the ladle is indicated by numeral 14 .

[0072] A stream of metal MS, shown by arrow M, enters the ladle through its open end 14 , flowing vertically downwards before hitting an impact zone 10i on the upper surface 10u of the ladle bottom 10 .

[0073] At least a part of the metal flow continues its flow (arrow F) towards a runner 16 arranged offset from said impingement zone 10i, which runner 16 extends from the upper surface 10u to the lower surface 10o.

[0074] Such as figure 1 As shown in , the runner 16 is filled with so-called filling sand FS, and a sand cone SC can be seen above the runner 16 . Filling material prevents molten metal from approaching the sprue during filling of the ladle. It...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap