Brake controller

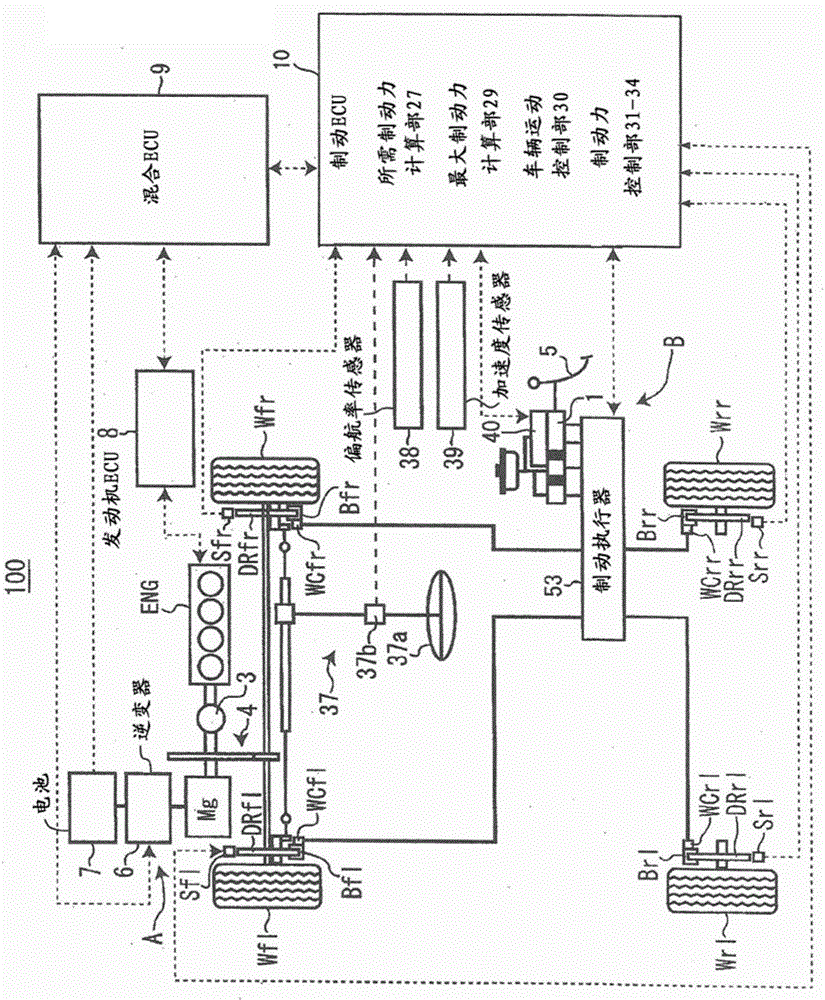

一种制动控制器、制动力的技术,应用在制动器、制动控制系统、制动组件等方向,能够解决摩擦制动力差等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

[0159] Next, a second embodiment will be described. According to the second embodiment, there is provided the same braking force control section 31 as the first embodiment (refer to figure 1 ) compared with the partially different braking force control unit 32. In addition to the control performed by the braking force control section 31, the braking force control section 32 sets the regenerative braking force Fcf to be generated at the left and right front wheels Wfl and Wfr to be equal to or smaller than The value obtained from the minimum frictional braking force generated at Wrl (hereinafter referred to as "rear wheel minimum braking force Frmin"). The rear wheel minimum braking force Frmin is set by the vehicle motion control section 30 so that the posture of the vehicle 100 is stabilized during the braking operation. The rear wheel minimum braking force Frmin is set based on the required braking force Fd, steering angle, vehicle speed V, forward / rearward acceleration, l...

no. 3 approach

[0167] Next, a third embodiment will be described. According to the third embodiment, there is provided the same braking force control section 31 of the first embodiment and the braking force control section 32 of the second embodiment (see figure 1 ) compared with the braking force control unit 33 which is partially different. The braking force control section 33 sets the left-right distribution ratio of the braking force Fr to the right rear wheel Wrr / left rear wheel Wrl so that the vehicle attitude is in a steady state. When the braking force control section 33 sets the left-right distribution ratio of the braking force, the friction brake device B is operated based on the left-right distribution ratio to generate the friction braking forces Fmrr and Fmrl.

[0168]At this time, as will be described in detail later, when the frictional braking force Fmrr to be generated at one of the right rear wheel Wrr / left rear wheel Wrl (for example, at the right rear wheel Wrr) exceeds...

no. 4 approach

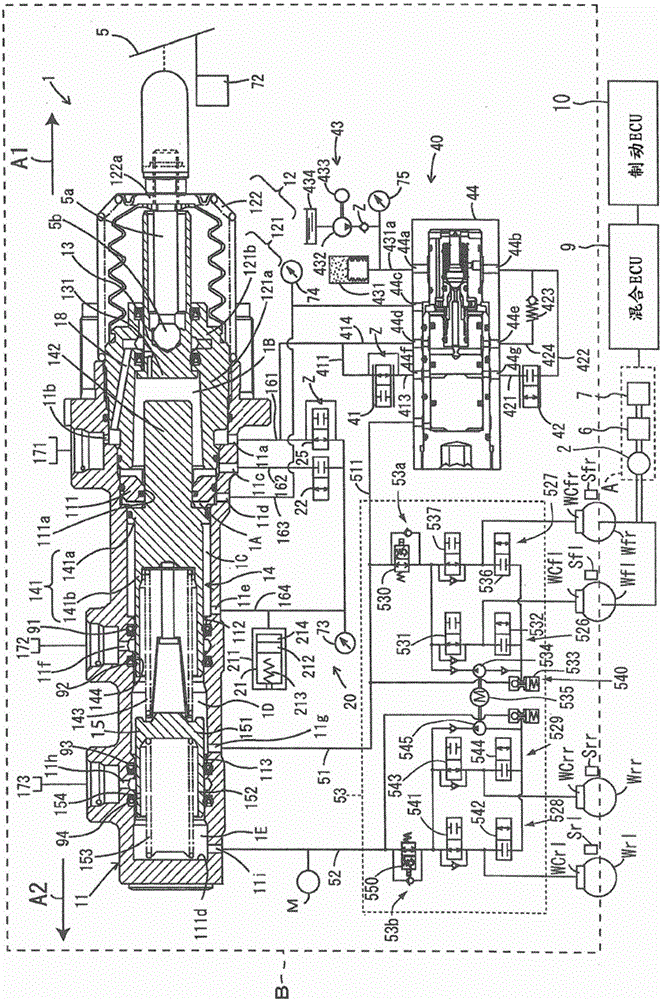

[0181] Next, a fourth embodiment will be described. According to the fourth embodiment, the operation of the friction brake device B is different from that of the corresponding friction brake devices B of the first to third embodiments. Specifically, in the friction brake device B, when the brake actuator 53 is not operated and the brake pedal 5 is depressed, the respective wheel cylinders WCfl, WCfr, WCrl and WCrl of the corresponding wheels Wfl, Wfr, Wrl and Wrr are WCrr provides uniform hydraulic pressure. Friction braking forces Fmfl, Fmfr, Fmrl, and Fmrr corresponding to the uniform hydraulic pressure are generated at the respective wheels Wfl, Wfr, Wrl, and Wrr. This uniform hydraulic pressure is a hydraulic pressure corresponding to the depression of the brake pedal 5 by the operator of the vehicle, and is to be supplied from the master cylinder 1 to each of the wheel cylinders WCfl, WCfr, WCrl, and WCrr. In this fourth embodiment, such a case is assumed.

[0182] Fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com