Washing and/or dewatering plants for cellulose pulp

一种纤维素纸浆、纸浆的技术,应用在纸浆脱水、纸浆打浆/精浆方法、纤维原料处理等方向,能够解决孔堵塞等问题,达到高能力、好洗涤的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the drawings, similar or corresponding elements are marked with the same reference signs.

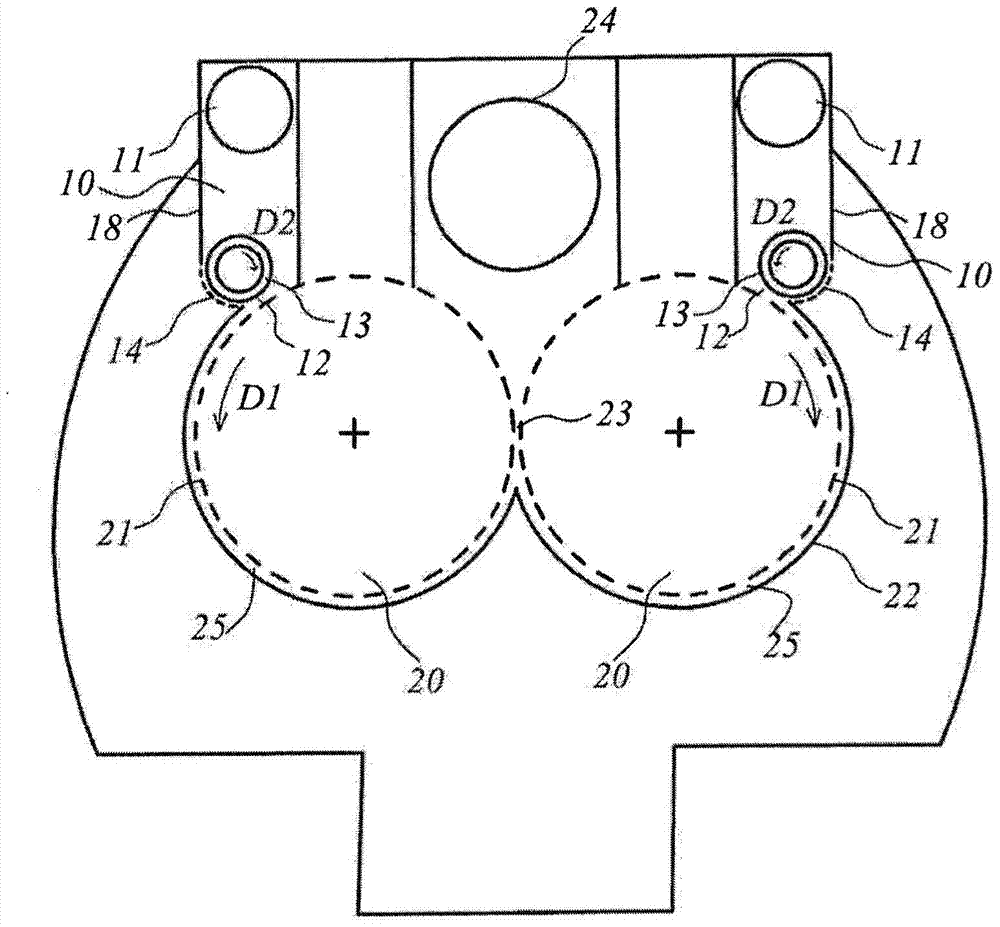

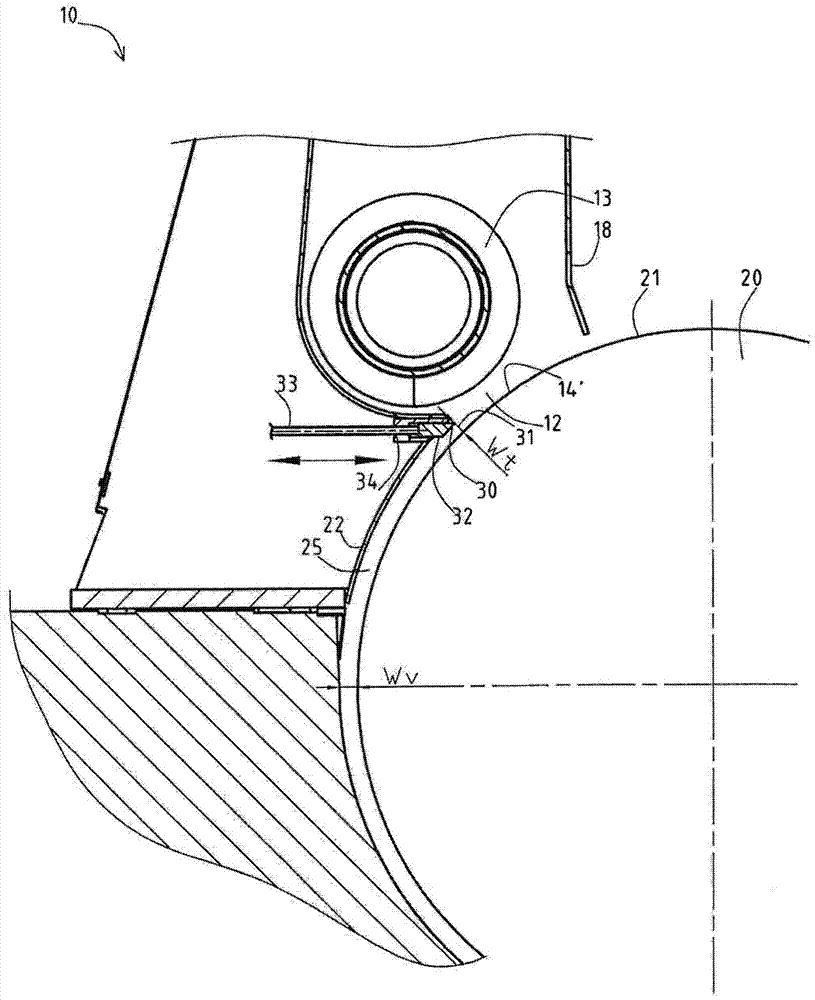

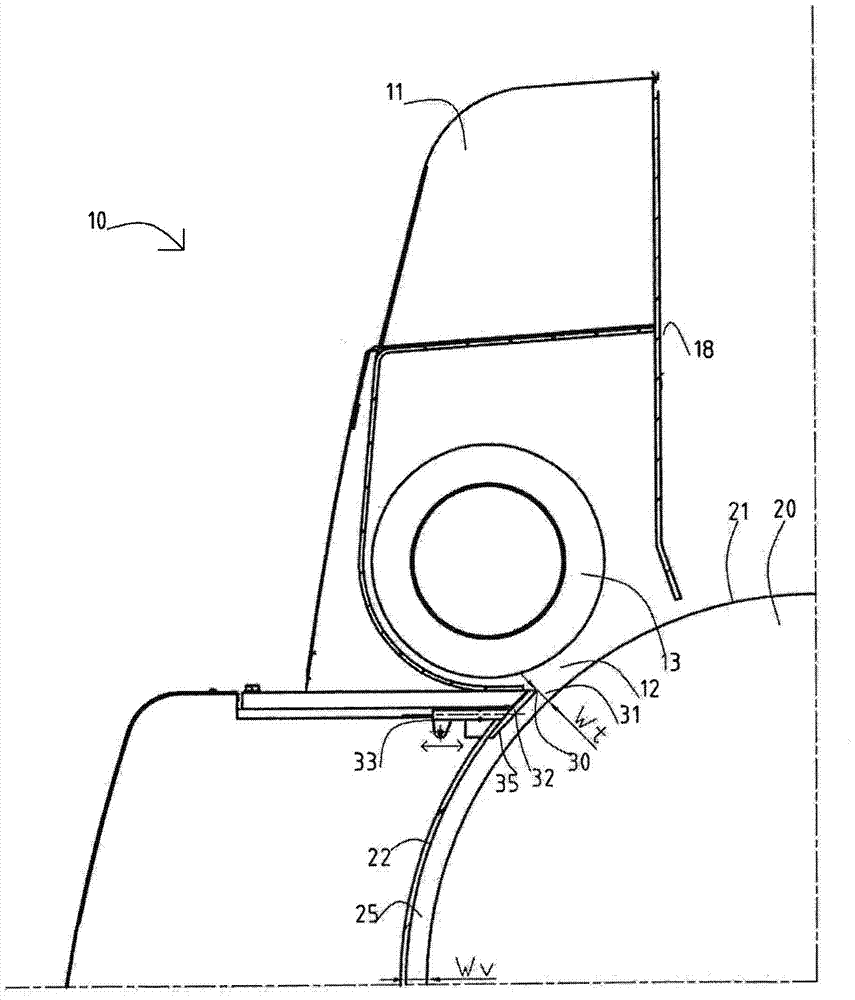

[0017] figure 1 A washing and / or dewatering device 100 for cellulose pulp is shown. The device 100 is in the form of a two-roll press 100 in this example. The device 100 includes two cylindrical press rolls 20 cooperating. The two press rolls 20 are arranged to rotate in opposite directions (as indicated by the arrows) during operation, and each have a first rotatable permeable surface 21, more specifically, a perforated metal plate or the like. The press roll 20 is partially circumferentially surrounded by grooves (also called grooves). The groove includes a groove wall 22 and a groove chamber 25 formed by a guide surface.

[0018] A pulp distribution device 10 is associated with each press roll 20. The pulp distribution device 10 is arranged at the upper part of the press roll 20 for distributing the pulp onto the perforated roll surface 21. The pulp distribution device 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com