Decorative method for forming body

A technology for moldings and decorative layers, which can be used in decorative arts, devices for coating liquid on surfaces, special decorative structures, etc., and can solve problems such as deterioration of the working environment, impact, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0083] A thermoplastic IMC reagent (pragrass #8000 green) manufactured by Dainippon Paint Co., Ltd. was used as the resin composition. This reagent is a mixture of 100 parts (mass) base reagent and 2 parts (mass) curing agent. The basic reagent consists of 68% (mass) of urethane acrylate (containing cross-linked antioxidants and polymerized antioxidants), 30% (mass) of inorganic components (cobalt oxide) and 2% (mass) of additives (such as Pigment dispersant, internal model release agent, etc.). Described solidifying agent is by the organic peroxide of 50% (mass) (peroxydicarbonate two (4-tert-butyl cyclohexyl ester); the Perkadox 16 that chemical medicine AKZO Co., Ltd. produces) and the plasticizing solvent of 50% (mass) (dibutyl phthalate) composition. The viscosity of this mixture is 5 Pa·s.

[0084] On the other hand, a flat plate forming body 1, which measures 90 mm x 40 mm x 3.0 mm, is molded from ABS resin (manufactured by DAICEL Chemical Industry Co., Ltd.; Cevian ...

example 2

[0091] 5 parts (quality) of titanium dioxide pigment (Netherlands TOPFINE company system, Toifine R41), 0.05 part (quality) of magenta pigment (Netherlands CIBA-GEIGY company system, Irgalith Rubine4BP), 0.05 part (quality) of cyan pigment (Netherlands CIBA- GEIGY, Irgalith blueLGLD) was mixed with 0.05 parts (by mass) of a yellow pigment (Cromophal Yellow 6G, CIBA-GEIGY, Netherlands) to prepare a coloring material.

[0092] Then, by mixing 100 parts (mass) of the base reagent with 2 parts (mass) of the curing agent, a resin composition having a viscosity of 5 Pa·s was prepared. The basic reagent consists of 68% (mass) urethane acrylate (containing cross-linking antioxidant and polymerization antioxidant), 30% (mass) of the above-mentioned coloring material and 2% (mass) of additives (such as pigment dispersant, internal mold release agent, etc.). Described solidifying agent is by the organic peroxide of 50% (mass) (peroxydicarbonate two (4-tert-butyl cyclohexyl ester); the P...

example 3

[0103] A resin composition and a molded body 1 similar to those in Example 1 were used.

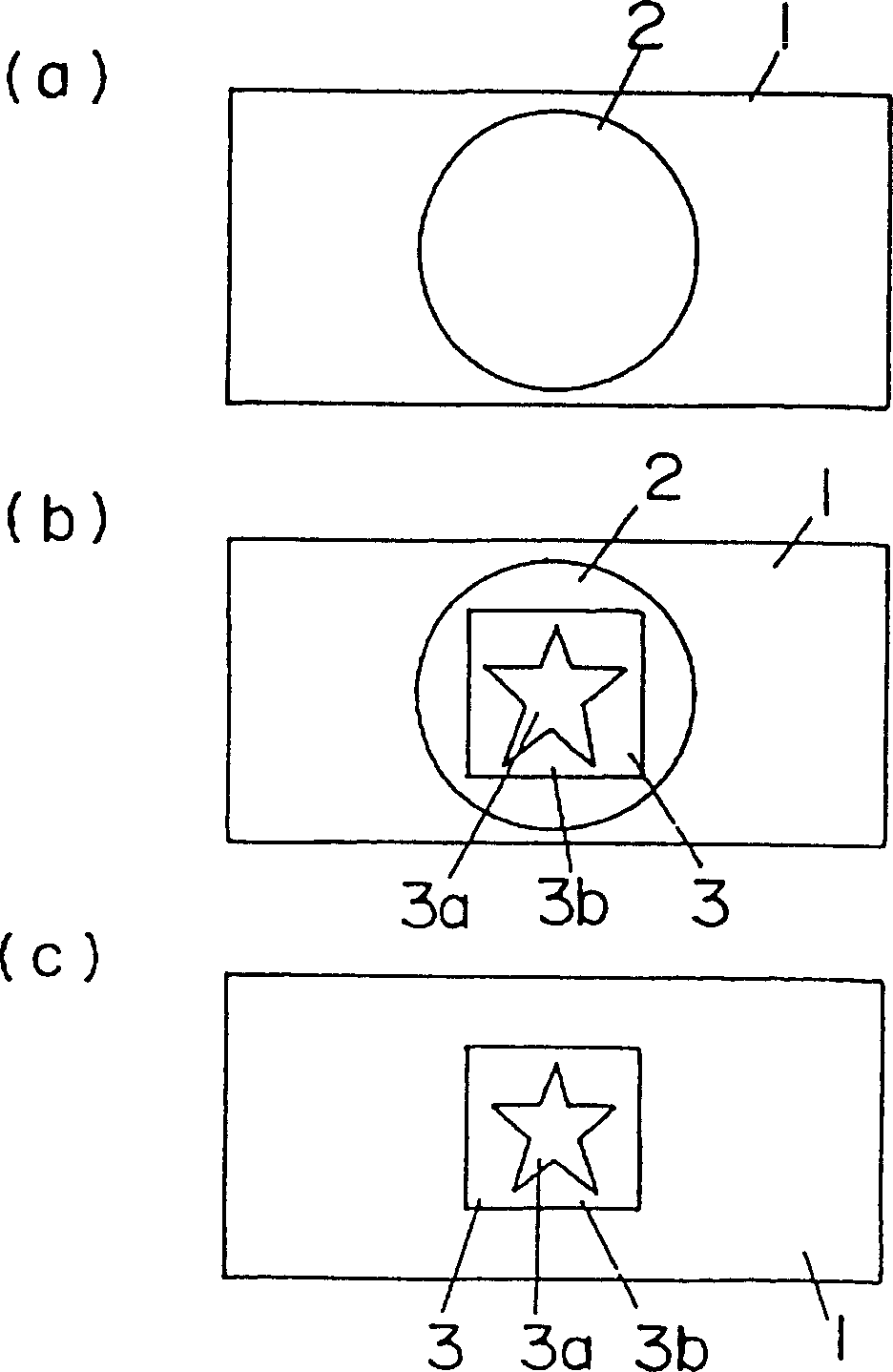

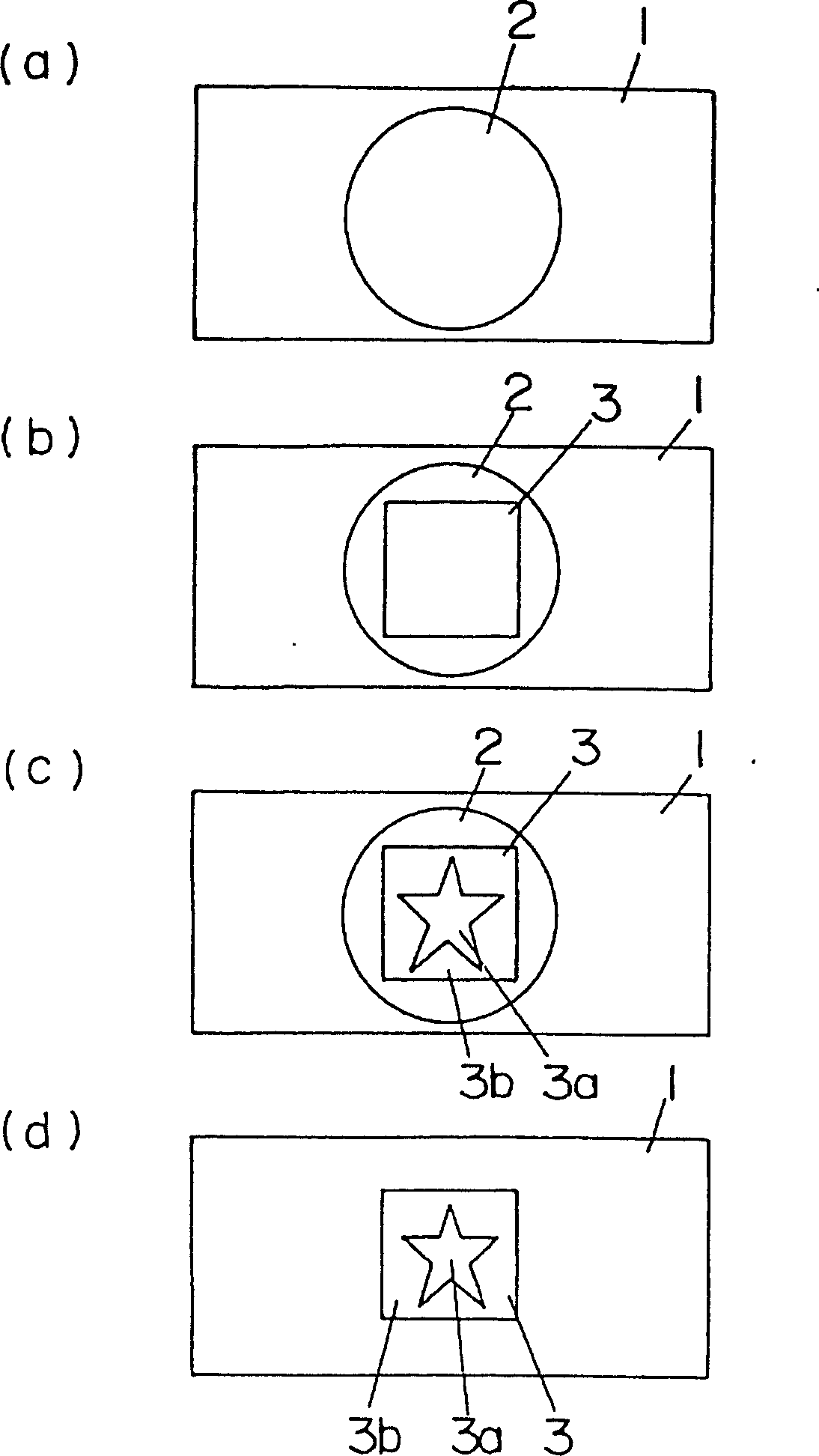

[0104] Such as figure 2 As shown in (a), a resin composition is used to form a circular coating layer 2 in plan view on the surface of a molded body 1 .

[0105] In this coating film layer 2, the entire area of 30 mm x 30 mm was irradiated with a laser beam under the following conditions. Thus, the coating film layer 2 is cured to form a figure 2 (b) The surface decoration layer 3 shown.

[0106] a. Using a semiconductor laser oscillator manufactured by Spectra-Physics, at a wavelength of 795nm, CW (continuous wave) oscillation, output 2.5w, spot diameter Φ1.5mm, scanning speed 2.5mm / sec, and irradiation time 0.6sec Irradiation of a laser beam is carried out.

[0107] Furthermore, in this surface decoration layer 3, further figure 2 The star-shaped area 3a shown in (c) is divided into a plurality of sub-areas, and each divided sub-area is irradiated with a laser beam under the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tackiness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com