Organic waste deodorizer and preparation method thereof

A technology for organic waste and deodorant, applied in deodorization, disinfection and other directions, can solve the problems of complex and diverse components, large discharge, weight reduction, and difficulty in deodorization, and achieves high treatment efficiency, low production cost, and production investment. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

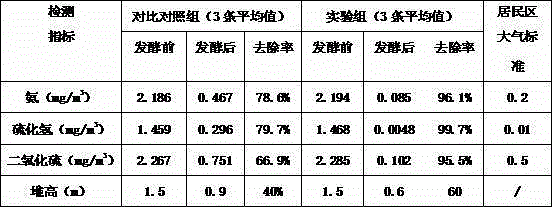

Image

Examples

Embodiment 1

[0022] An organic garbage deodorant, the raw materials in parts by weight are: 40 parts of mushroom leftovers, 2 parts of Bacillus subtilis, 2 parts of nitrous bacteria, 2 parts of sulfur bacteria, and 2 parts of Thiobacillus denitrification.

[0023] The preparation method of described organic garbage deodorant, concrete steps are:

[0024] (1) Activate and culture Bacillus subtilis, nitrous bacteria, sulfur bacteria and Thiobacillus denitrificans respectively;

[0025] (2) First prepare the mushroom waste into a fermentation medium with a mass concentration of 200g / L, and place it in a fermentation tank with stirring and temperature control functions;

[0026] (3) Inoculate the Bacillus subtilis, nitrous bacteria, sulfur bacteria, and Thiobacillus denitrifica that have been activated and cultured in step (1) into the fermentation medium prepared in step (2), and expand the culture at a speed of 180rpm for 72 Hours, culture temperature is 28 ℃;

[0027] (4) The filtrate is ...

Embodiment 2

[0029] An organic garbage deodorant, the raw materials in parts by weight are: 50 parts of mushroom leftovers, 1.5 parts of Bacillus subtilis, 1.5 parts of nitrous bacteria, 1.5 parts of sulfur bacteria, and 1.5 parts of Thiobacillus denitrification.

[0030] The preparation method of described organic garbage deodorant, concrete steps are:

[0031] (1) Activate and culture Bacillus subtilis, nitrous bacteria, sulfur bacteria and Thiobacillus denitrificans respectively;

[0032] (2) First prepare the mushroom waste into a fermentation medium with a mass concentration of 150g / L, and place it in a fermentation tank with stirring and temperature control functions;

[0033] (3) Inoculate the Bacillus subtilis, nitrous bacteria, sulfur bacteria, and Thiobacillus denitrificans that have been activated and cultured in step (1) into the fermentation medium prepared in step (2), and expand the culture at a speed of 200rpm for 48 Hours, culture temperature is 32 ℃;

[0034] (4) The fi...

Embodiment 3

[0036] An organic garbage deodorant, the raw materials in parts by weight are: 60 parts of mushroom leftovers, 1 part of Bacillus subtilis, 1 part of nitrous bacteria, 1 part of sulfur bacteria, and 1 part of Thiobacillus denitrification.

[0037] The preparation method of described organic garbage deodorant, concrete steps are:

[0038] (1) Activate and culture Bacillus subtilis, nitrous bacteria, sulfur bacteria and Thiobacillus denitrificans respectively;

[0039] (2) First prepare the mushroom waste into a fermentation medium with a mass concentration of 100g / L, and place it in a fermentation tank with stirring and temperature control functions;

[0040] (3) Inoculate the Bacillus subtilis, nitrous bacteria, sulfur bacteria and Thiobacillus denitrifica that have been activated and cultured in step (1) into the fermentation medium prepared in step (2), and expand the culture at 220rpm for 24 Hours, culture temperature is 38 ℃;

[0041] (4) The filtrate is obtained by filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com