A membrane module with a filler inside

A technology of filler and membrane module, which is applied in the field of water purification, can solve the problems of increasing energy consumption, membrane pollution, and reducing the service life of membranes, so as to achieve the effect of reducing pollution load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

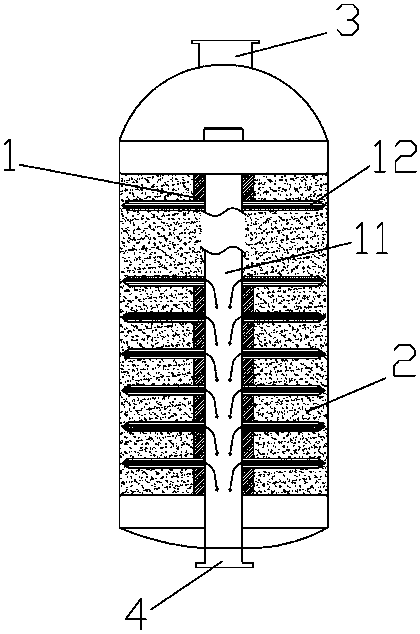

[0031] Embodiment 1: A membrane module with a filler inside, a membrane element 1 is arranged in the membrane module, a filling space is arranged in the membrane module, and activated carbon particle filler 2 is filled in the filling space.

[0032] The membrane module adopts a terminal filtration structure, and the membrane module is provided with a feed inlet 3 and a clean water outlet 4 .

[0033] The membrane element 1 is a plurality of membranes 12 fixed on the flow column 11. The membrane 12 includes an outer filter side and an inner permeate side. The permeate side communicates with the flow column 11, and the permeate flows out from the flow column 11. ; The filling space is the gap between the filter side of the membrane element and the shell of the membrane module, and the filling space is filled with activated carbon particles.

Embodiment 2

[0034] Embodiment 2: A membrane module with a filler inside, a membrane element 1 is arranged in the membrane module, a filling space is arranged in the membrane module, and a filler 2 mixed with activated carbon particles and porous resin particles is filled in the filling space .

[0035] The membrane module adopts a terminal filtration structure, and the membrane module is provided with a feed inlet 3 and a clean water outlet 4 .

[0036] The membrane element 1 is a plurality of membranes 12 fixed on the flow column 11. The membrane 12 includes an outer filter side and an inner permeate side. The permeate side communicates with the flow column 11, and the permeate flows out from the flow column 11. ; The filling space is the gap between the filter side of the membrane element and the housing of the membrane module, and the filling space is filled with fillers.

Embodiment 3

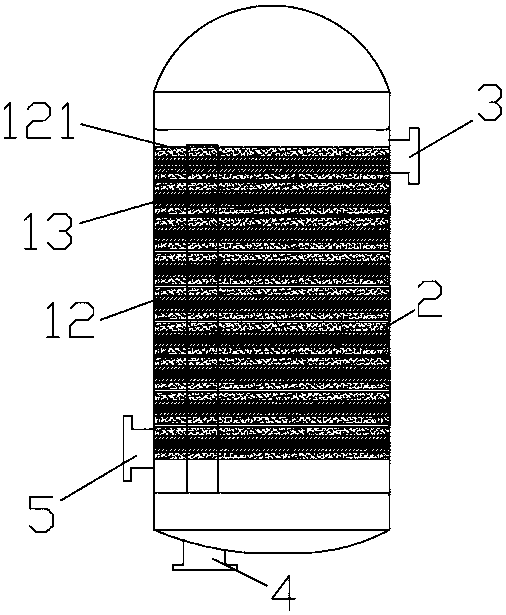

[0037] Embodiment 3: A membrane module with a filler inside. A membrane element 1 is arranged in the membrane module, a filling space is arranged in the membrane module, and a natural zeolite particle filler 2 is filled in the filling space.

[0038] The membrane module adopts a cross-flow filtration structure, and the membrane module is provided with a feed inlet 3 , a clean water outlet 4 and a discharge outlet 5 .

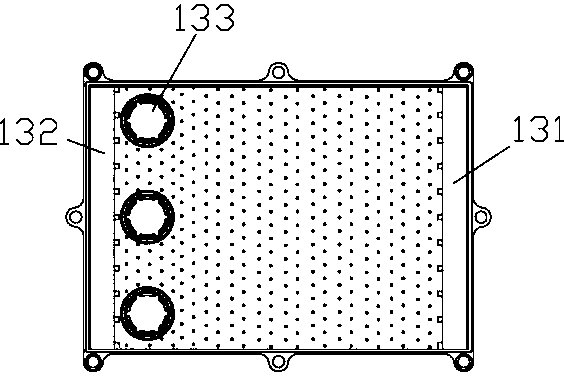

[0039] The membrane element is an assembly consisting of several sets of flow channel plates 13 and diaphragms 12 connected to the flow channel plates. The flow channel plates 13 are provided with raw material liquid inlets 131 and circulating liquid outlets 132. A permeate outlet 133 is provided.

[0040] The surface of the diaphragm 12 is provided with a filter screen 121, and there is no opening between the filter screen 121 and the surface of the diaphragm 12 except the pores of the filter screen 121. The filter screen 121 and the surface of the diaphragm 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com