Fine-adjustment center water discharging eccentric boring cutter

A technology of eccentric boring tool and eccentric block with water outlet, applied to boring heads, accessories of tool holders, tools used in lathes, etc., can solve problems such as damage to tools and workpieces, prevent outflow, avoid excessive vibration, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

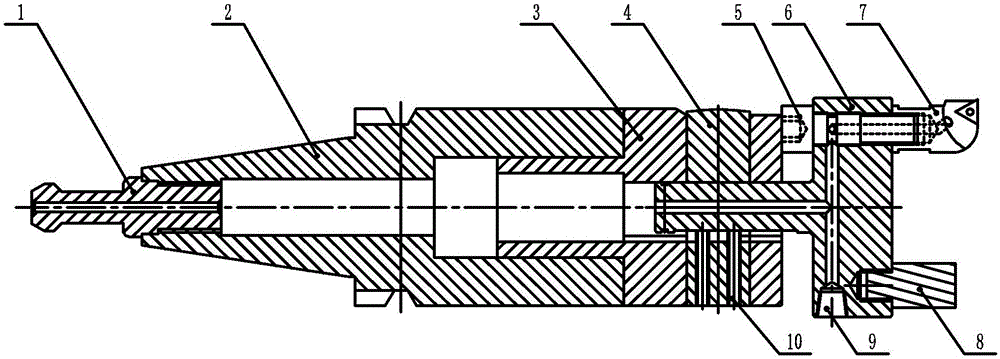

[0022] combined with figure 1 , an eccentric boring tool with fine-tuning center outlet, including pull stud 1, ST40 handle 2 and boring head body 3 installed in sequence, and also includes a blade seat 7 and eccentric block 6; the center of the boring head body 3 is provided with a through hole, and the eccentric block 6 is installed in the through hole of the boring head body 3, the hole diameter of the boring head body 3 is slightly larger than the eccentric block 6, and the eccentric block 6 and the boring head body 3 are connected together through the fine-tuning mechanism 4 and the set screw 10; the insert seat 7 is installed On one side of the eccentric block 6.

[0023] Wherein, there is scale on the outer cylindrical surface of fine-tuning mechanism 4, and its scale value f is

[0024] f = ( a + r ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com