Installation aligning method for shafting

A shafting and coaxial technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of low energy consumption, poor reliability of centrifugal fan operation, etc., to simplify steps and reduce shafting installation and alignment time, to ensure the effect of adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

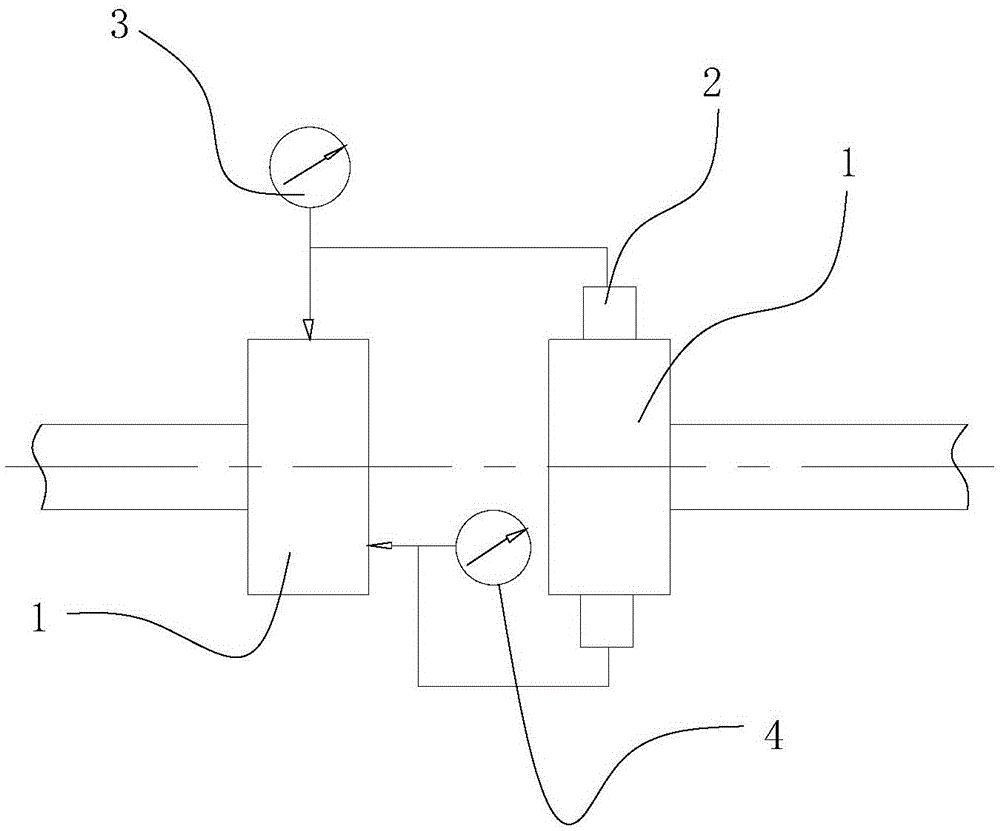

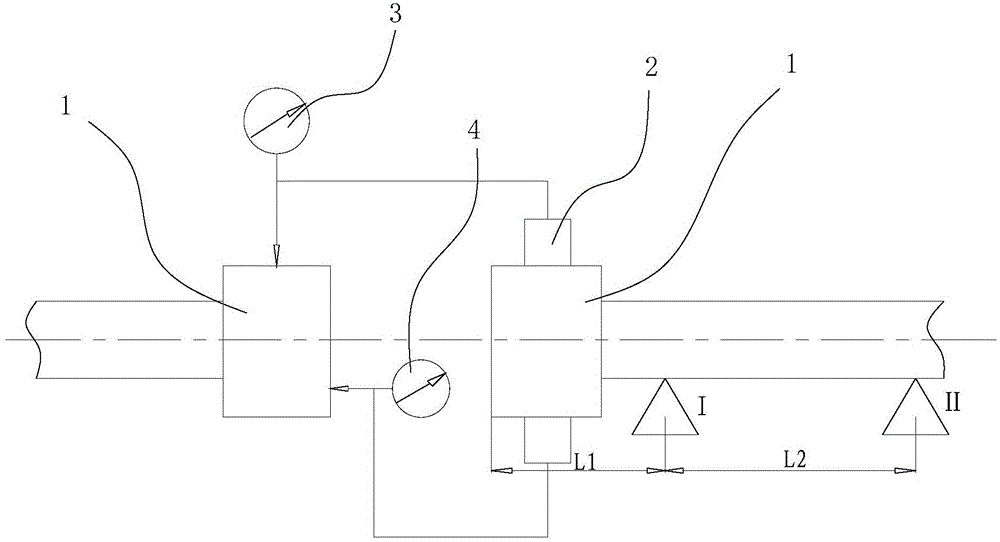

[0092] like figure 2 As shown, it is a schematic diagram of the alignment of the motor shaft and the transmission shaft. The shaft installation and alignment method of the present invention is used to align the rotating shaft of the motor and the transmission shaft.

[0093] like figure 2 As shown, first install the coupling 1 on the two connecting shafts that need to be connected; then realize the installation alignment through the following steps.

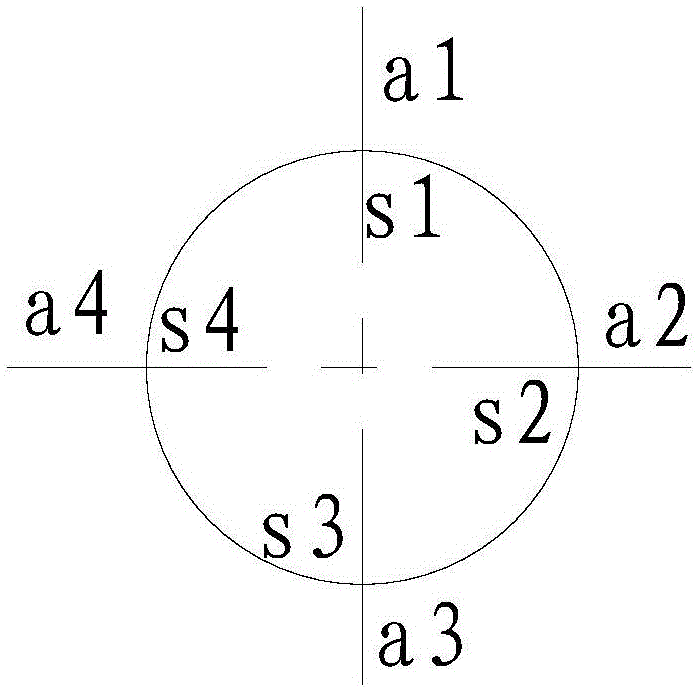

[0094] 1) Determine the transmission shaft as the reference shaft and the motor shaft as the adjustment shaft, and measure the radial deviation a in the vertical direction of the coupling 1 on the adjustment shaft relative to the coupling 1 on the reference shaft through the measuring device 竖 , the radial deviation a in the horizontal direction 水 , the end face deviation S in the vertical direction 竖 , the end face deviation S in the horizontal direction 水 ; the end face deviation S in the vertical direction 竖 Refers to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com