Sheet metal assembly device

A technology for assembling devices and sheets, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of visual correction process influence and high environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

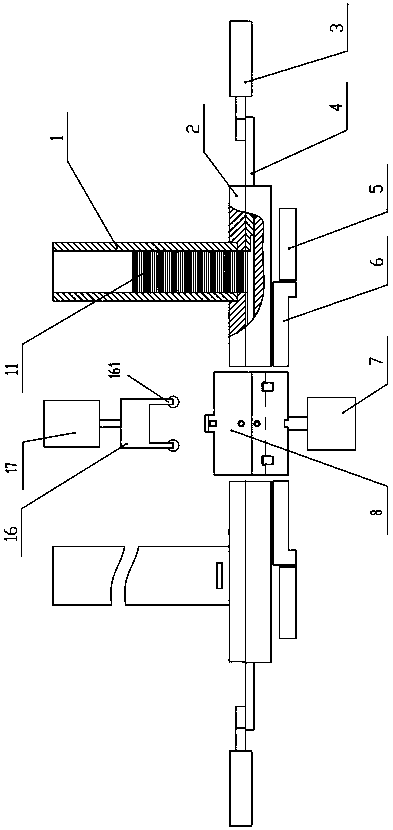

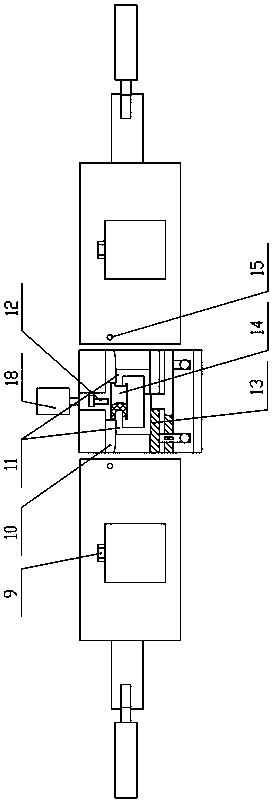

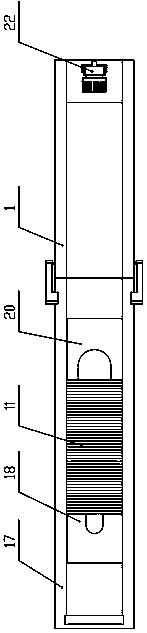

[0029] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

[0030] Sheet metal assembly devices such as figure 1 , figure 2 As shown in the figure, 1 is the feed bin, 2 is the base, 3 is the feeding cylinder for pushing the sheet metal, 4 is the push rod, 5 is the secondary forming assembly cylinder, 6 is the secondary forming push rod, 7 is the servo motor, 8 is the assembly carrier, 9 is the material detection sensor, 10 is the positioning block, 11 is the sheet metal, 12 is the pressing block, 13 is the guide flow channel, 14 is the parts to be assembled, 15 is the discharge detection sensor, 16 is the pressing Block, 17 is a compression cylinder, and 18 is an assembly carrier to promote the cylinder.

[0031] In the middle of the sheet metal assembly device is an assembly carrier 8 for placing assembly parts 14 .

[0032] The pressing block 16 is provided with an indenter 161 corresponding to the thin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com