High speed shaft pin machine

A shaft pin machine, high-speed technology, applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve the problems of unguaranteed product quality, poor length consistency, unreasonable design, etc., to improve production efficiency, The effect of small length error and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

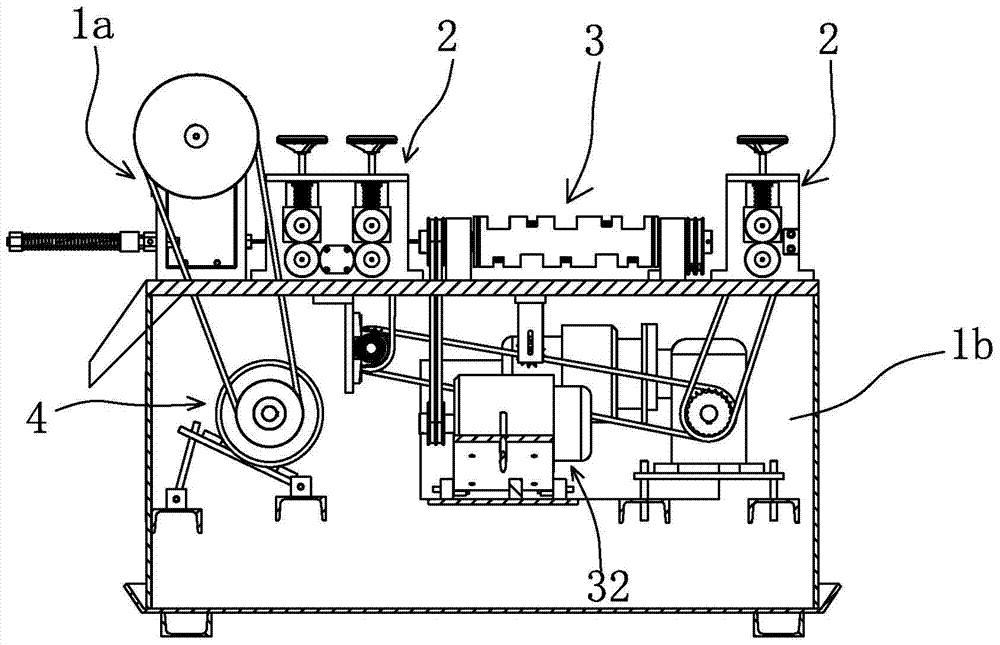

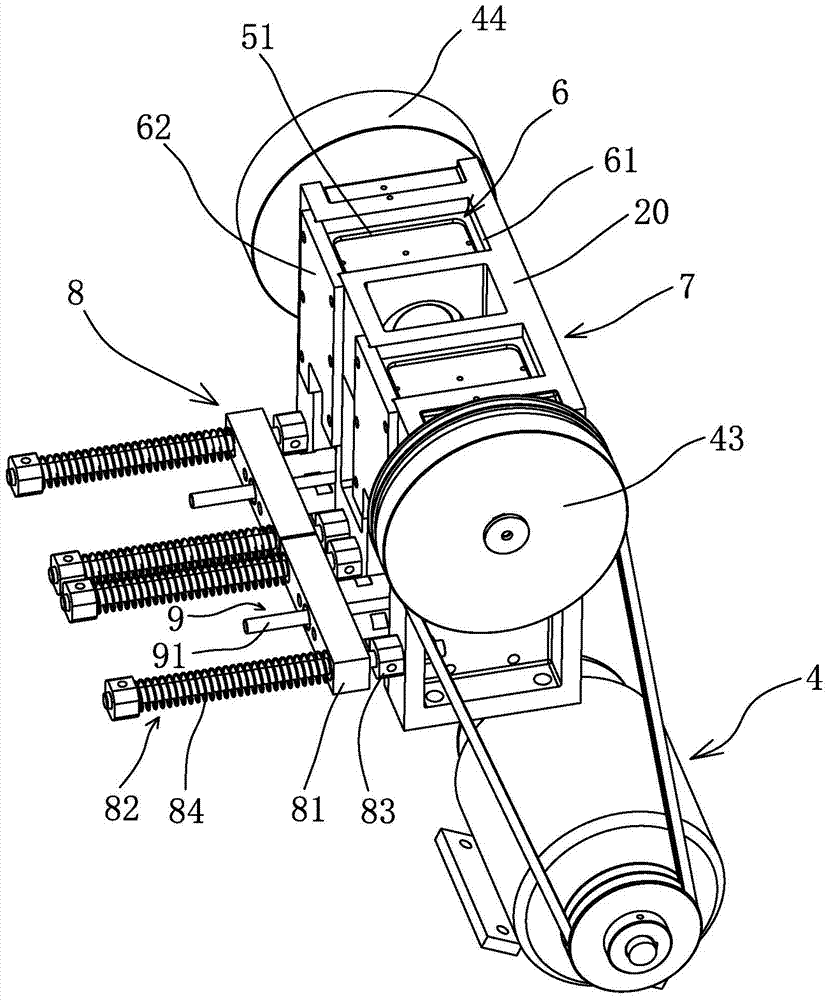

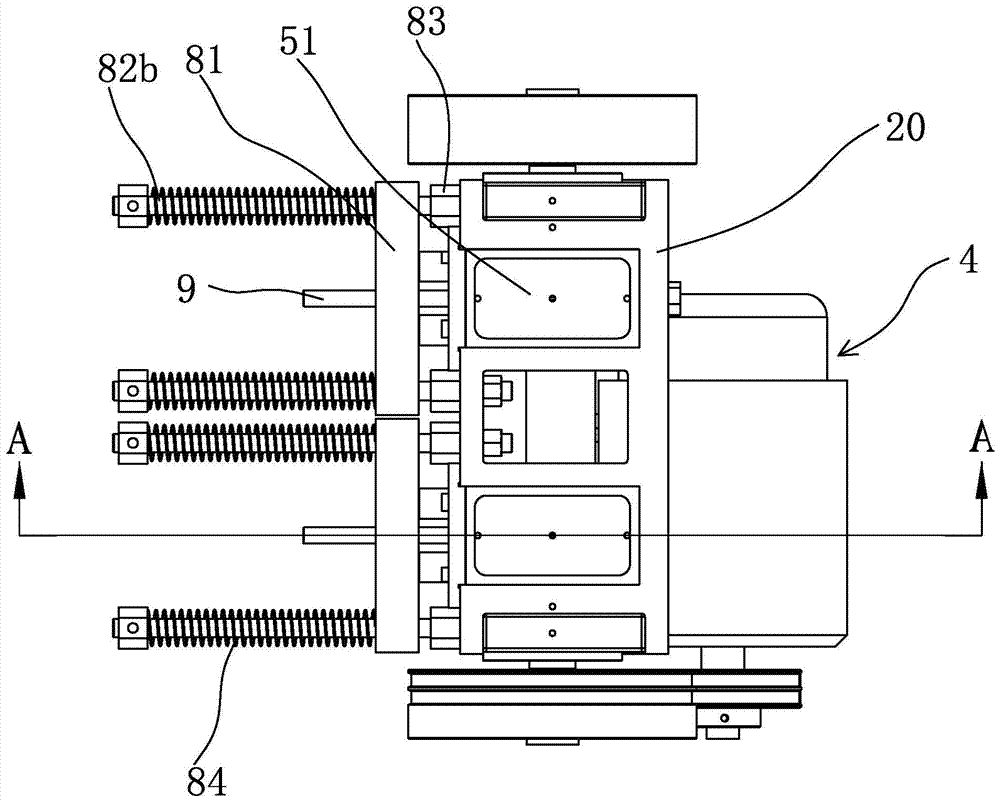

[0035] Such as figure 1 , figure 2 As shown, the high-speed shaft pin machine includes a frame 1b, and the frame 1b is provided with a feeding mechanism 2 for conveying the strip material and a cutting device 1a capable of cutting the strip material, and the cutting device 1a It includes a base 20 on which a fixed knife 10 and a moving knife 1 arranged end-to-end are arranged. The fixed knife 10 and the moving knife 1 are both cylindrical and the strip-shaped material output from the feeding mechanism 2 can be It is installed in the fixed knife 10 and the moving knife 1. The moving knife 1 is fixed in the horizontal direction and movable in the vertical direction. The moving knife driving mechanism 7 is characterized in that the base 20 is provided with a translational sliding fixed-length mechanism 8, and the translational sliding fixed-length mechanism 8 is arranged at the discharge end of the movable knife 1 and can be installed in the The ends of the strip material in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com