Matrix type 3D printer and printing method thereof

A 3D printer, matrix technology, applied in the direction of additive processing, etc., can solve the problem that 3D printers cannot be mass-produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1, a matrix 3D printer.

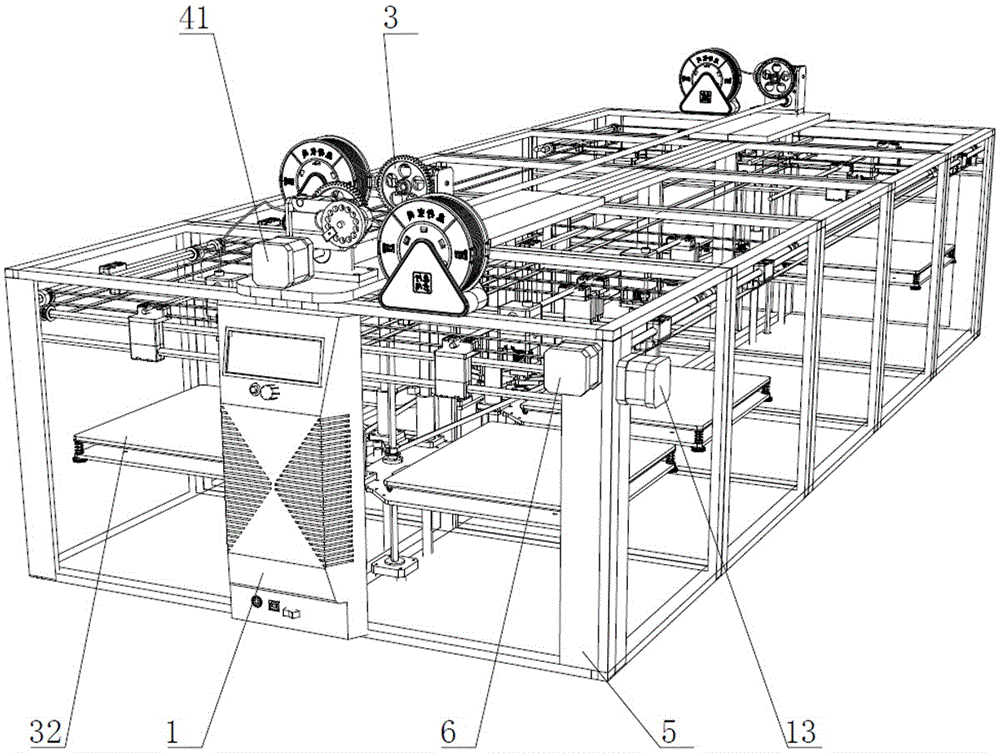

[0051] Such as figure 1 As shown, the present invention includes a frame 5, a printing platform 32, a printing mechanism, an X-axis driving mechanism, a Y-axis driving mechanism, a Z-axis driving mechanism, a feeding mechanism, a material abnormality processing mechanism, and a control mechanism 1.

[0052] Specifically, the rack 5 is composed of a metal frame, and each rack 5 is connected and combined to form a matrix structure; each metal frame constitutes a station, in the figure there are 10 stations with 2 rows and 5 columns.

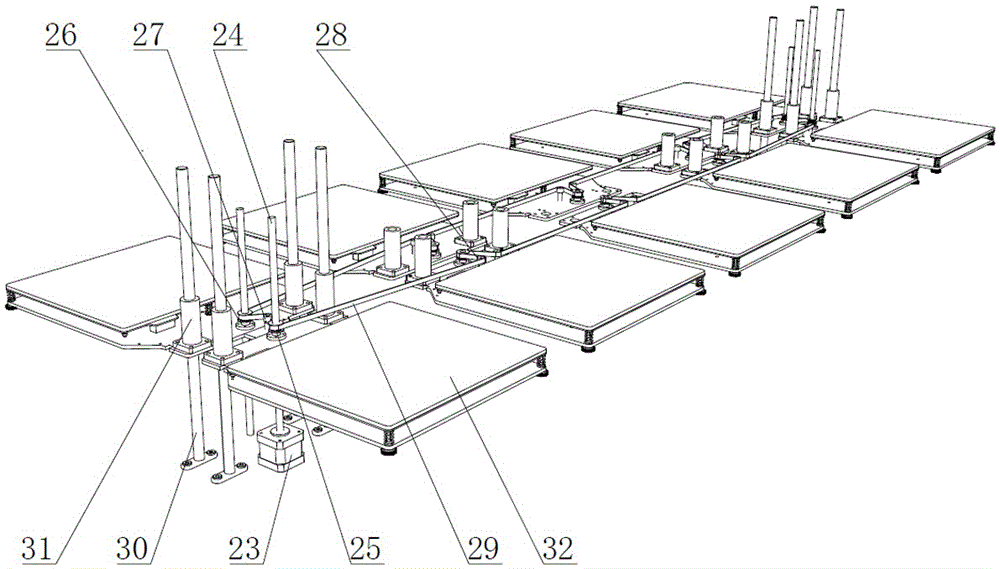

[0053] The printing platform 32 is a platform for carrying printed products. In the present invention, the printing platform 32 corresponds to the frame 5 one by one, and the printing platform 32 is located inside the corresponding frame 5. The printing platforms 32 are distributed in a matrix.

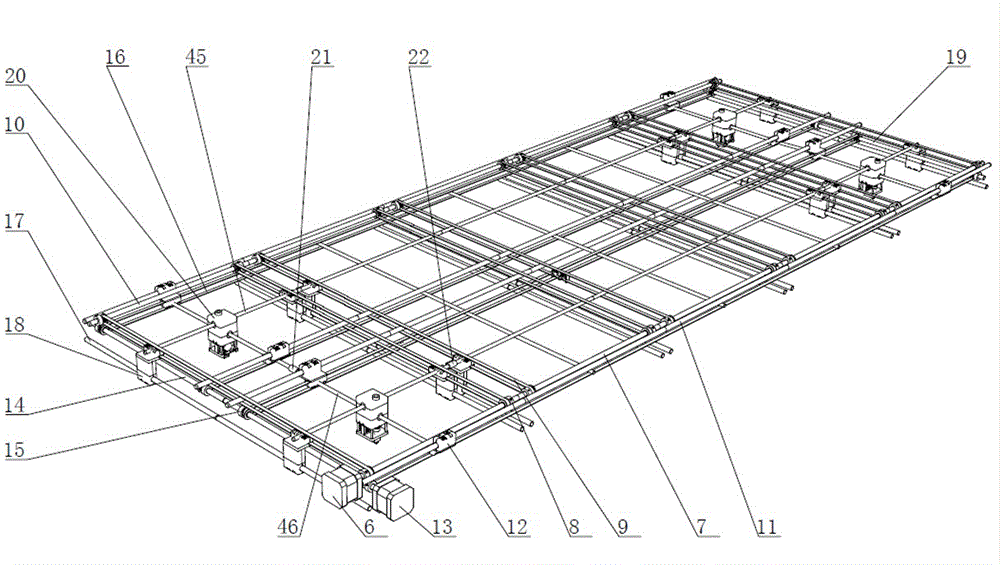

[0054] The printing mechanism is composed of a number of print heads 20 distributed in a matrix (see figure 2 ) Composit...

Embodiment 2

[0072] Embodiment 2, the alarm device of the matrix 3D printer.

[0073] The alarm device of the matrix 3D printer in this embodiment includes a number of material abnormality handling mechanisms one-to-one corresponding to each material supply body in the matrix 3D printer; the material abnormality handling mechanism can detect the output of the filaments on each station in real time Check whether there is any difference, and send out an alarm signal when there is an abnormal situation in the material wire at a certain station, so as to check and deal with it in time. Refer to the description in Example 1 for the material abnormality handling mechanism.

Embodiment 3

[0074] Embodiment 3, the printing method of the matrix 3D printer.

[0075] The printing method of the matrix 3D printer in this embodiment adopts the matrix 3D printer in Embodiment 1 in the execution process, and the specific structure of the matrix 3D printer can be referred to the description in Embodiment 1. The printing method of the matrix 3D printer includes the following steps:

[0076] ① The horizontal position of all print heads is relatively leveled by the control mechanism through the print head leveling system.

[0077] ② Adjust the printing platform and printing mechanism to the initial position through the control mechanism. The control mechanism adjusts the position of the printing platform through the Z-axis drive mechanism; the control mechanism adjusts the position of the print mechanism through the X-axis drive mechanism and the Y-axis drive mechanism.

[0078] ③ The control mechanism controls the feeding mechanism to provide printing filaments to all the print h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com