Device for preventing walking wheels from locking

A traveling wheel, together technology, applied in the direction of wheel, axle combination, transportation and packaging, etc., can solve the problem of power output mechanism locking traveling wheel, traveling wheel locking, etc., and achieves structural design solution, resistance reduction, and maintenance reduction. Effects of cost and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

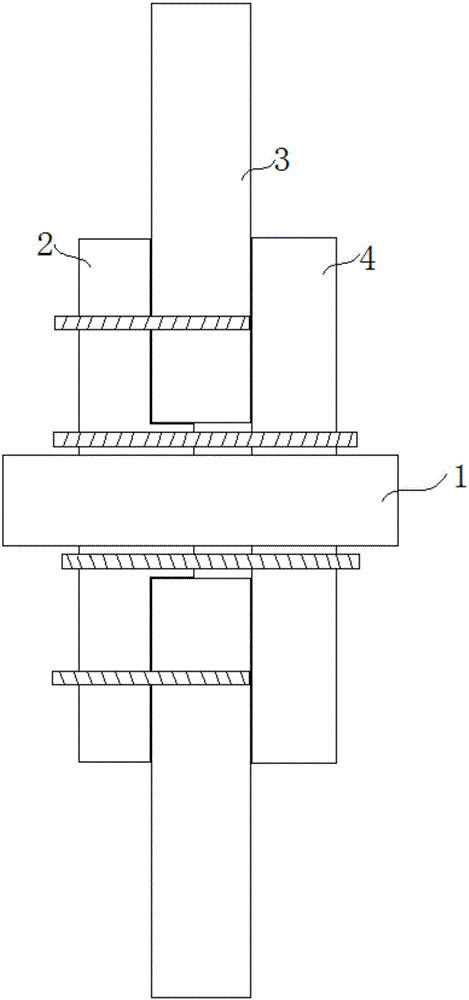

[0037] Hydraulic drive has been widely used in various fields, and it has also been widely used in agricultural machinery in recent years. Most of the agricultural machinery used for farmland operations is equipped with a closed hydraulic system. The existing farmland operation machinery is driven by a closed hydraulic motor to drive the road wheels to travel in the farmland. Once the hydraulic motor fails, the road wheels will be locked and unable to rotate due to the connection with the hydraulic motor, making the farmland operation machinery unable to move. Towed by a trailer, it can only be overhauled on site or forcibly towed, which greatly increases the cost and difficulty of subsequent overhauls. The device for preventing road wheel locking in this embodiment has a reasonable structural design, simple principle, and is economical and applicable. It can completely solve the fatal problem that a farmland operation machine with a hydraulic motor failure cannot be dragged, a...

Embodiment 2

[0043] The device for preventing road wheel locking of the present embodiment has the same basic structure as that of Embodiment 1, the difference being that:

[0044] The drive shaft 1 is driven to rotate by the internal combustion engine.

[0045] In non-hydraulic driven farmland operation machinery, when the power output mechanism breaks down, although the road wheels 3 can still rotate in most cases, sometimes when the power output mechanism is completely stuck, it will directly cause the road wheels 3 to be locked and die. Can't rotate, thereby can't drag this farmland operation machinery, perhaps even if road wheel 3 still can rotate, but because road wheel 3 is connected with power take-off mechanism, will certainly increase the resistance that road wheel 3 is subjected to when rotating, has increased dragging. The difficulty of moving this farmland operation machine is time-consuming and laborious; and when dragging this farmland operation machine, the traveling wheel ...

Embodiment 3

[0049] The device for preventing road wheel locking of the present embodiment has the same basic structure as that of Embodiment 1, the difference being that:

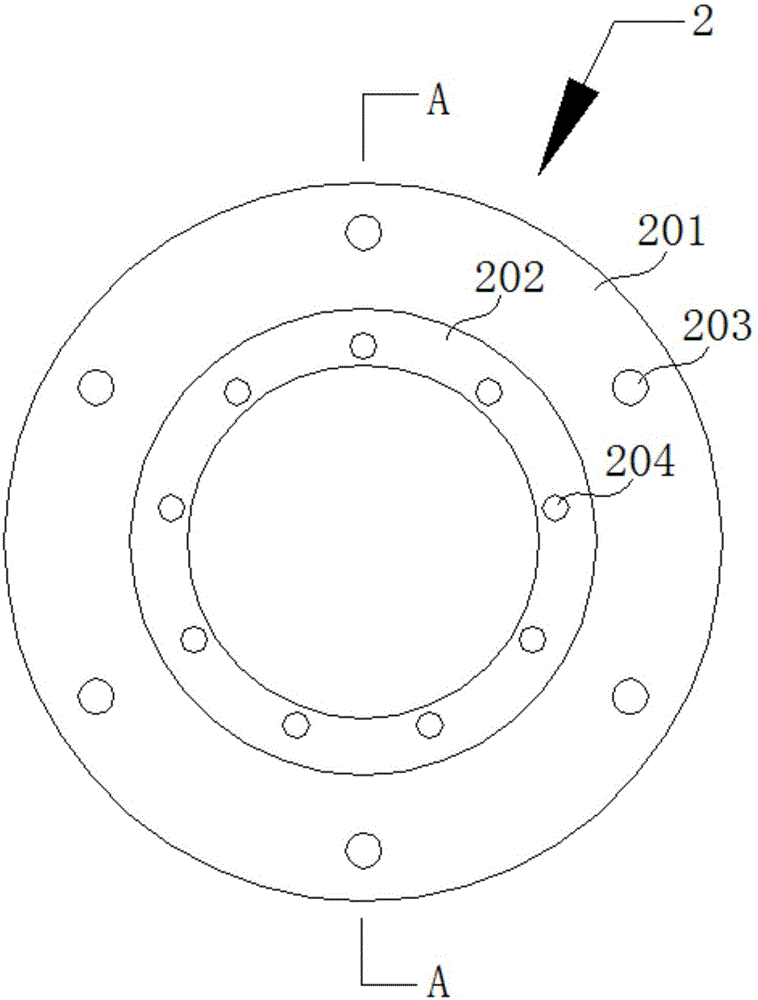

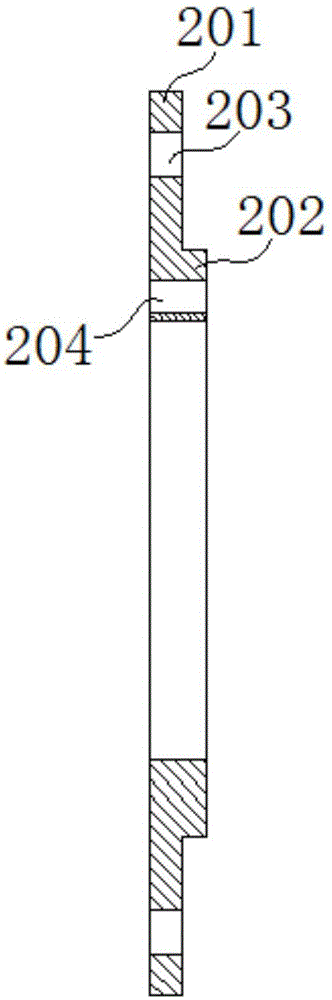

[0050] In order to ensure that the traveling wheel 3 can rotate normally on the boss 202 when the hydraulic motor breaks down, the width of the traveling wheel main body 301 is less than 1 mm from the distance between the outer disc 4 and the inner disc 2; 0.3mm outer diameter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com