A chemical fiber spinning machine for textile processing

A chemical fiber and silk machine technology, applied in the textile field, can solve the problems of short glass fiber smoothness blasting, uneven appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

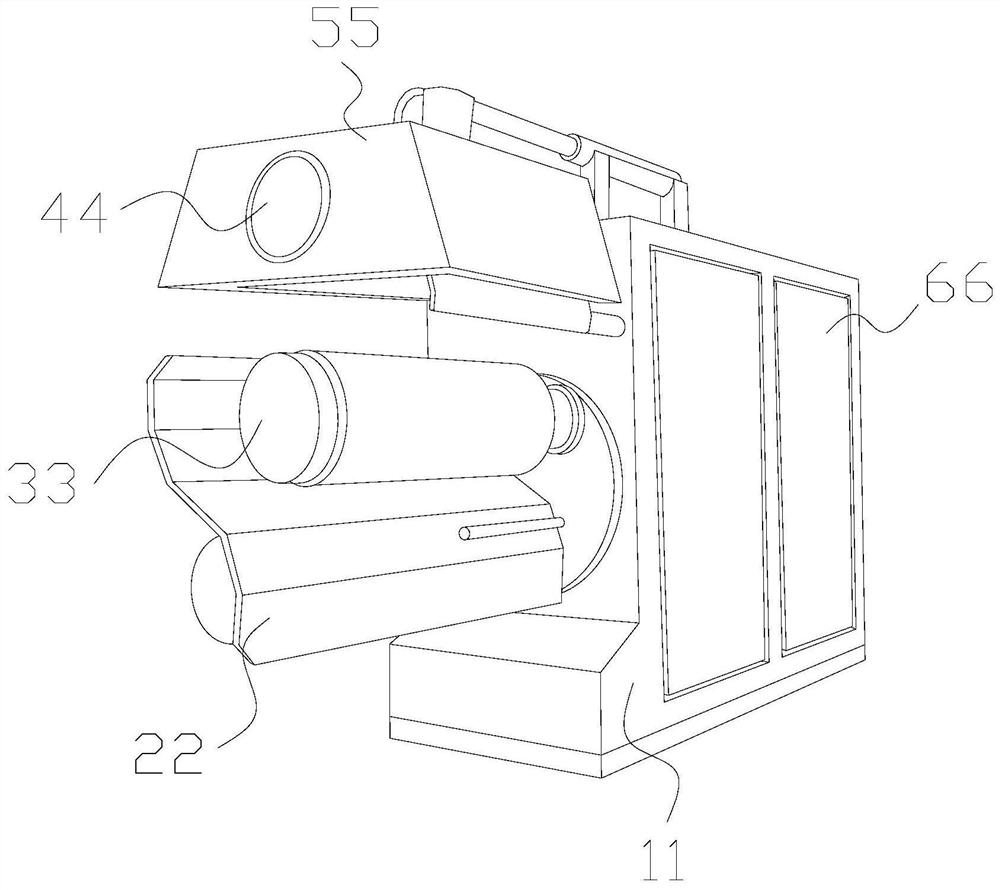

[0032] as attached figure 1 to attach Figure 9 Shown:

[0033] The present invention provides a chemical fiber spinning machine for textile processing, the structure of which includes a main drawing box 11 , a partition 22 , a main spinning reel 33 , a thread shaft 44 , a shield 55 and a control box 66 .

[0034] The control box 66 is connected with the main pumping box 11, the partition plate 22 is welded on the outer surface of the main pumping box 11, and the total drawing volume 33 is located below the silk shaft 44, and the silk shaft 44 is installed on the protective cover. Inside the cover 55.

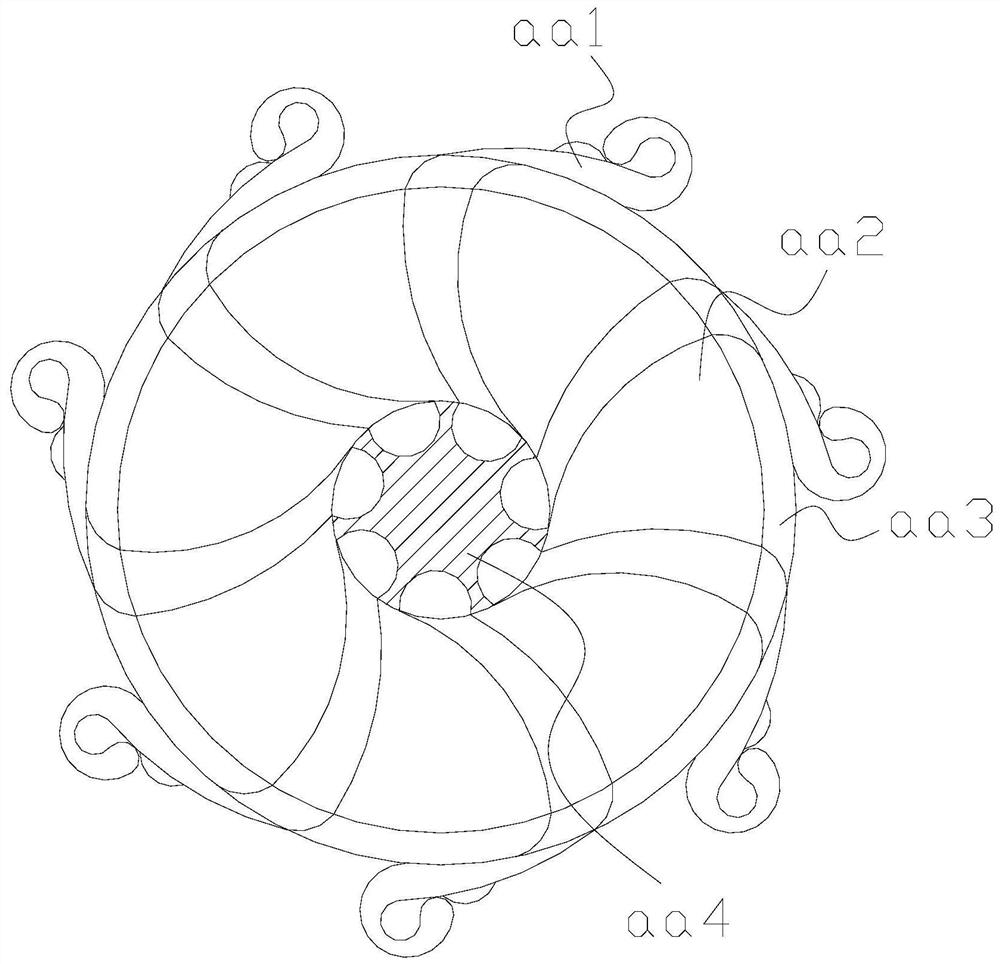

[0035] The thread shaft 44 includes a head winding strip aa1, an inner disk aa2, an outer ring aa3, and a middle solid end aa4. The head winding strip aa1 is installed inside the inner disk aa2, and the outer surface of the inner disk aa2 is against the outer ring aa3. The outer ring aa3 and the middle fixed end aa4 are located on the same axis.

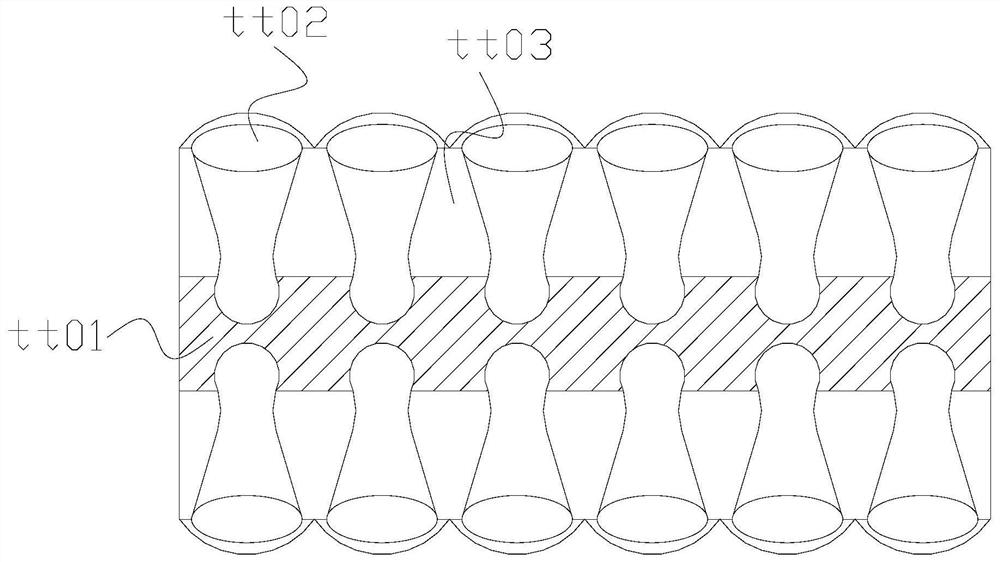

[0036] Wherein, the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com