Vertical elevator for goods

A technology for vertical elevators and goods, applied in conveyors, transportation and packaging, etc., can solve the problems of high labor intensity of staff, hinder the appearance of warehouses, and not suitable for storage of precision spare parts, etc., to improve the efficiency and convenience of material management. Distinguishing and identifying effects for easy instant access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

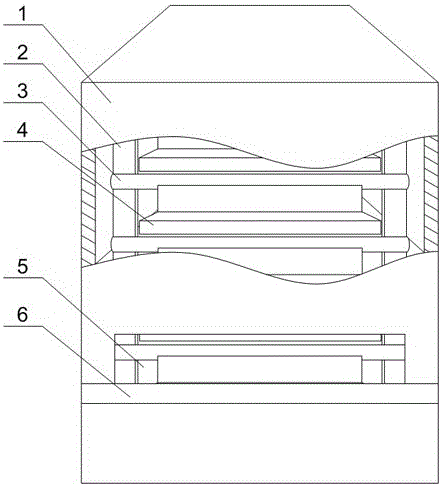

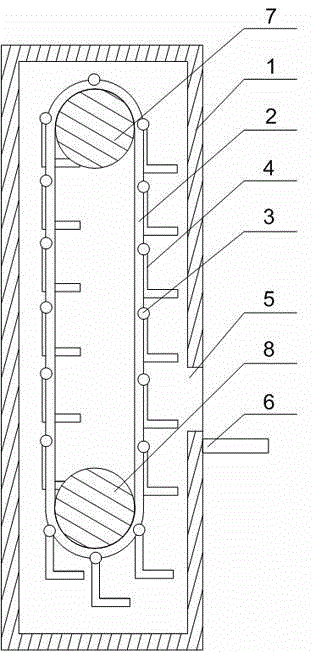

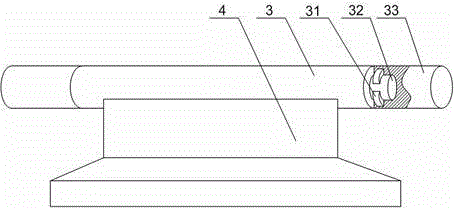

[0022] Such as Figure 1~Figure 4 As shown, the present embodiment includes a cabinet body 1, two motors and two groups of main sprocket 8 and driven sprocket 7 which are arranged on the inner wall of the cabinet body 1 for rotation, and the main sprocket 8 and driven sprocket 7 pass through the chain 2 Connection and cooperation, the output end of the motor is connected with the main sprocket 8, and the cabinet body 1 is provided with a delivery port 5, and also includes a plurality of rotating shafts 3, and the rotating shaft 3 is composed of a main body located in the middle section and fixed sections 33 at both ends. Composition, the hopper 4 is fixed on the main body, the fixed section 33 is embedded in the chain 2, and the movable cavity 34 with an elliptical cross section is arranged inside the fixed section 33, and the two ends of the main body are A narrowing section 32 is arranged on the outer extension, and two limiting blocks 31 whose thickness increases along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com