A self-adjustable knotting machine

A knotting machine and self-adjusting technology, applied in the field of knotting machines, can solve the problems of inability to perform complex knotting, poor generality of knotting machines, etc., and achieve the effects of high production efficiency, good completion, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

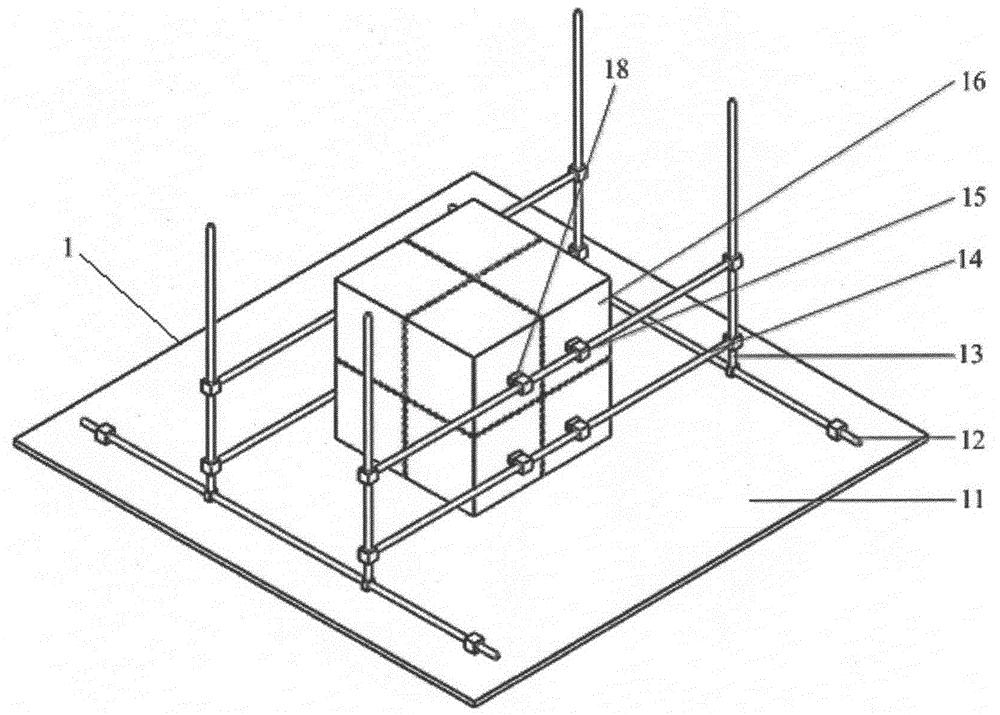

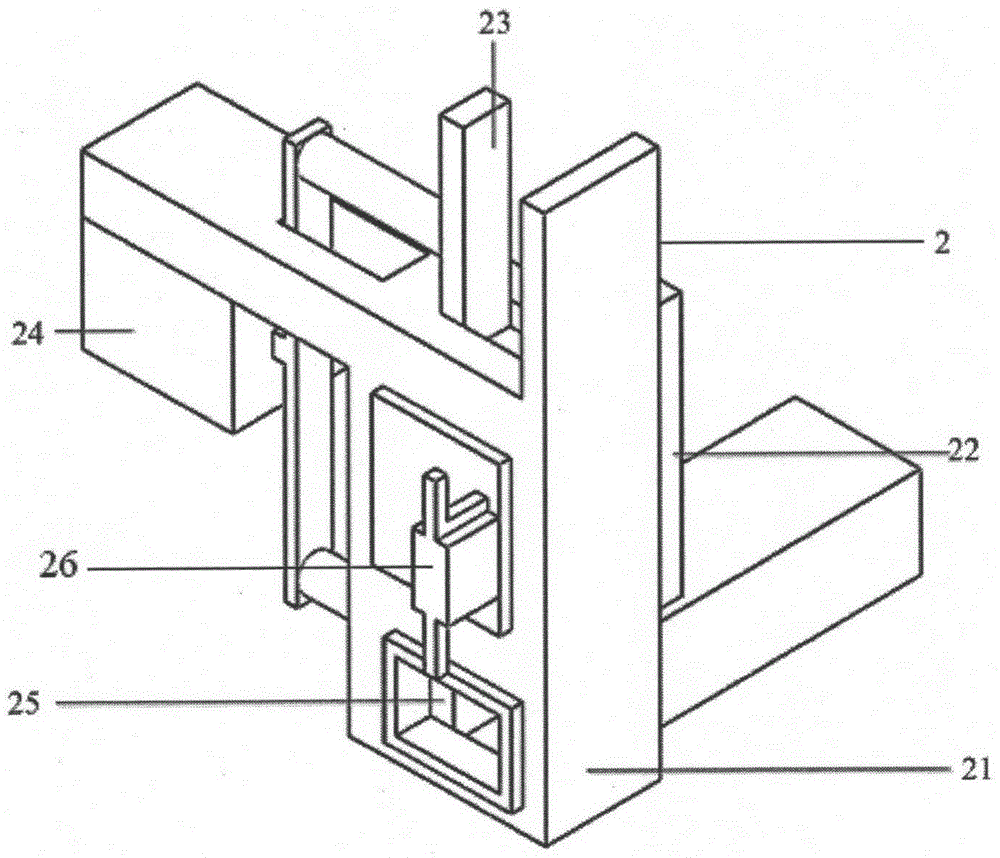

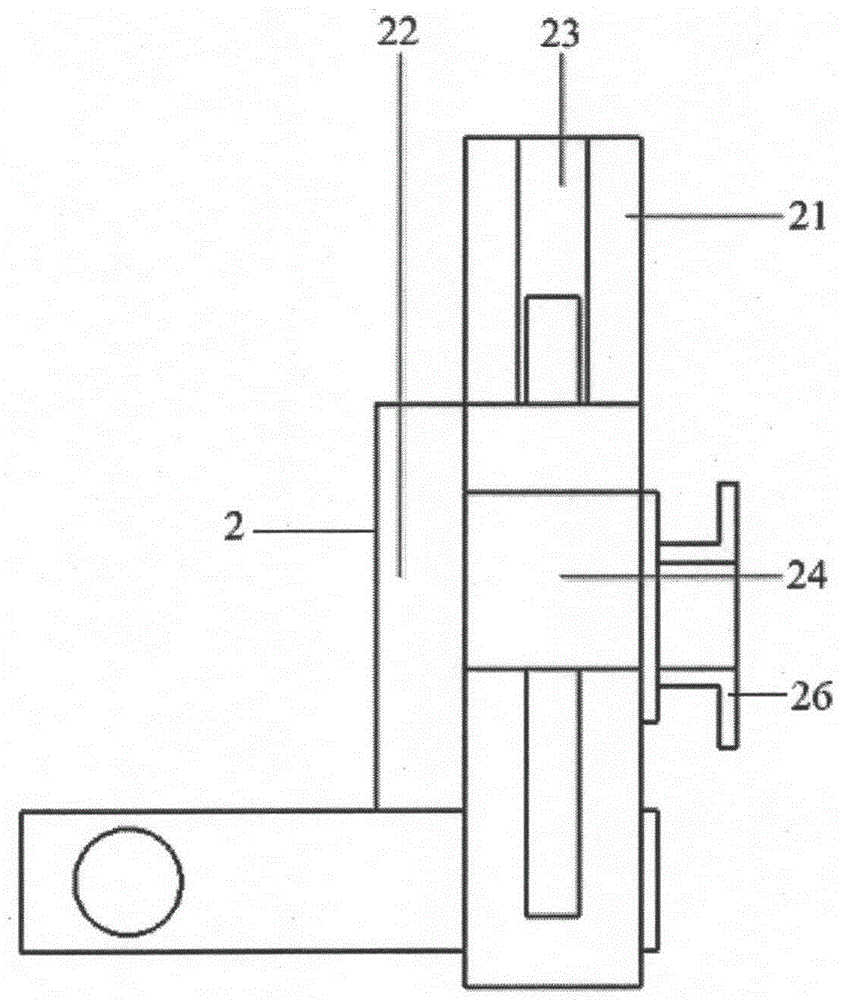

[0021] Such as Figure 1-9 As shown, the structure diagram of a self-adjustable knotting machine provided by the present invention includes a guide module 1 and a control module 2; wherein the guide module 1 includes a platform 11, a support bar 12, a horizontal slide bar 14, and a vertical slide bar 13. The slider 15, the knotting cavity 16, the air plug 17, the handle 18, the control module 2 includes a support 21, a sensor 22, an upper chuck 23, a cylinder 24, and a lower chuck 25. Two support bars 12 are installed on the platform 11, and two horizontal slide bars 14 are installed on each support bar 12 to enable the knotting chamber 16 to move horizontally. Vertical slide bar 13 can make knotting cavity 16 realize vertical movement, is provided with two slide blocks 15 on every vertical slide bar 13, and slide block 15 cooperates with handle 18, and handle 18 can be bonded on Knotting chamber 16, so as to control the displacement of each slide bar and slider 15 to change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com