Formwork reinforcing system replacing wood with steel and construction technology thereof in external wall construction

A formwork reinforcement and wood formwork technology, applied in the connection parts of formwork/formwork/work frame, formwork/formwork/work frame, formwork/formwork member, etc. The steel pipe cannot be lengthened at will, and cannot be placed in the air, so as to achieve the effect of high rigidity, low cost and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in detail below in conjunction with accompanying drawing:

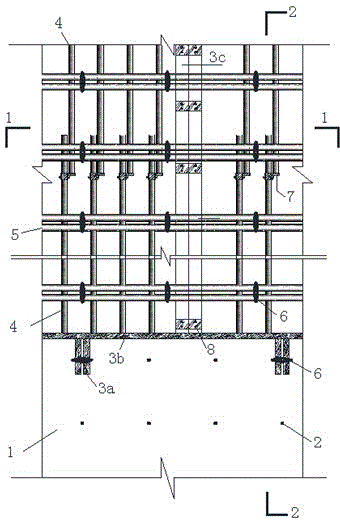

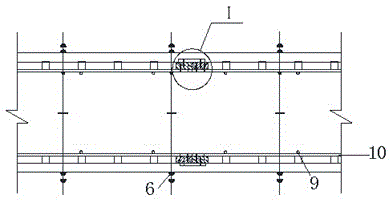

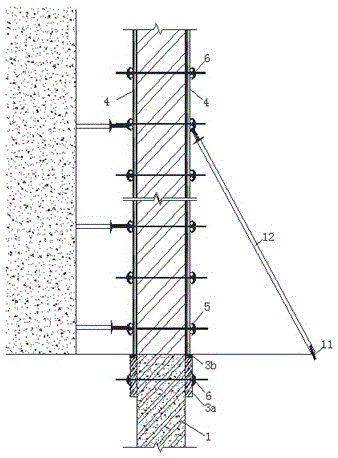

[0030] Such as Figure 1-5 As shown, a formwork reinforcement system with steel instead of wood is provided with a steel keel support assembly on the concrete structure wall 1, and the steel keel support assembly is composed of a vertical wooden square 3a and a horizontal wooden square 3b, and the vertical wooden square 3a Fixed at the top row of water-stop bolt holes 2 on both sides of the concrete structure wall 1, the vertical wooden squares 3a are symmetrically arranged in groups on both sides of the concrete structure wall 1, and the interval along the length of the wall is 1.2-1.5m There is one group, and the vertical wooden squares on both sides are fixed by tie bolts. Each group of vertical wooden squares 3a is composed of two wooden squares, and the upper part of the vertical wooden squares 3a is horizontally placed with a horizontal wooden square 3b. On the concrete...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap