Fully mechanized mining working face two-end excess elevation segment hydraulic supporting device

A fully mechanized mining face and hydraulic support technology, which is applied to mining equipment, earthwork drilling, mine roof supports, etc., can solve the problems of a large amount of waste and high-altitude operations, and achieve long service life, save construction costs, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

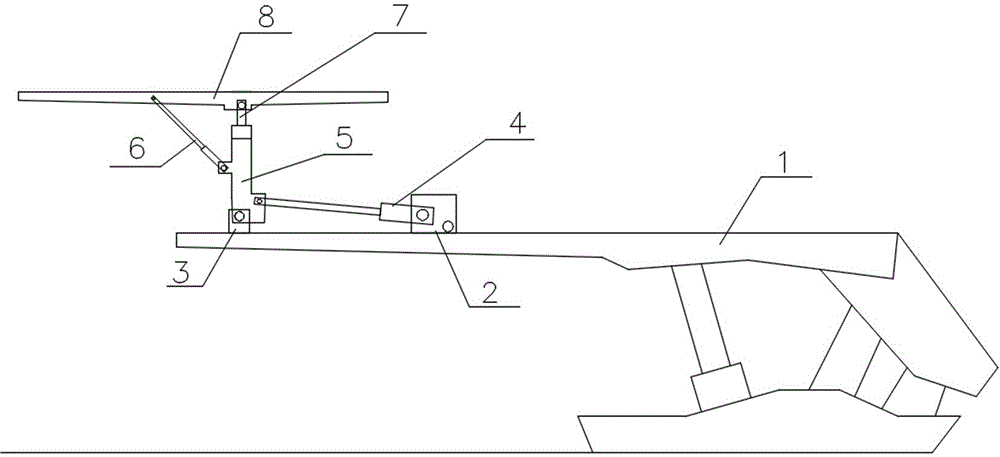

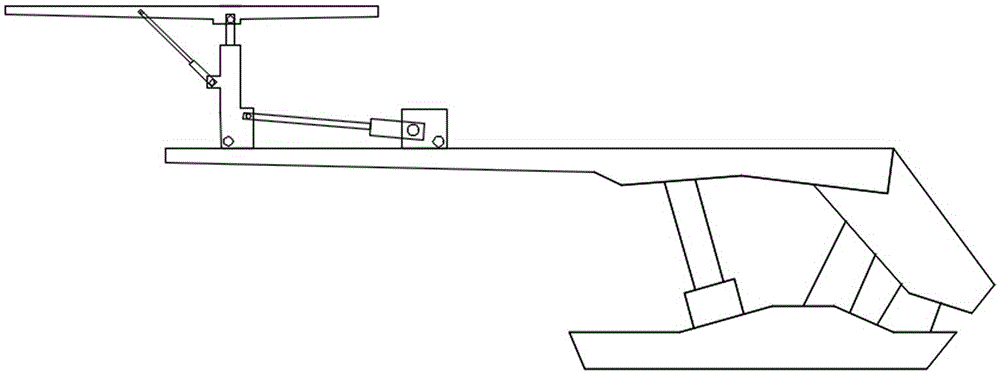

[0014] The hydraulic support device at both ends of the fully mechanized mining face over the superelevation section includes two sets of hydraulic telescopic supports arranged side by side fixed by U-shaped channel steel on the existing support, and each group of hydraulic telescopic supports includes U-shaped channel steel fixed In the rear fixed support 2 on the support 1, the front side of the rear fixed support 2 is provided with the front fixed support 3 utilizing U-shaped channel steel to be fixed on the support 1, and the front of the rear fixed support 2 is hinged with an overturning oil cylinder 4. An overturning beam 5 is hinged above the fixed support 3, the front end of the telescopic rod of the overturning oil cylinder 4 is hinged to the middle part of the overturning beam 5, and a lifting cylinder 7 is fixed above the overturning beam 5, and the front end of the telescoping rod of the lifting cylinder 7 is hinged to a horizontally arranged support plate 8 , the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com