A kind of spring cement shock absorber

A shock absorber and cement technology, applied in the direction of spring/shock absorber, shock absorber, spring, etc., can solve the problems of high material cost, difficult reset, complex structure, etc., and achieve simple production, easy reset, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

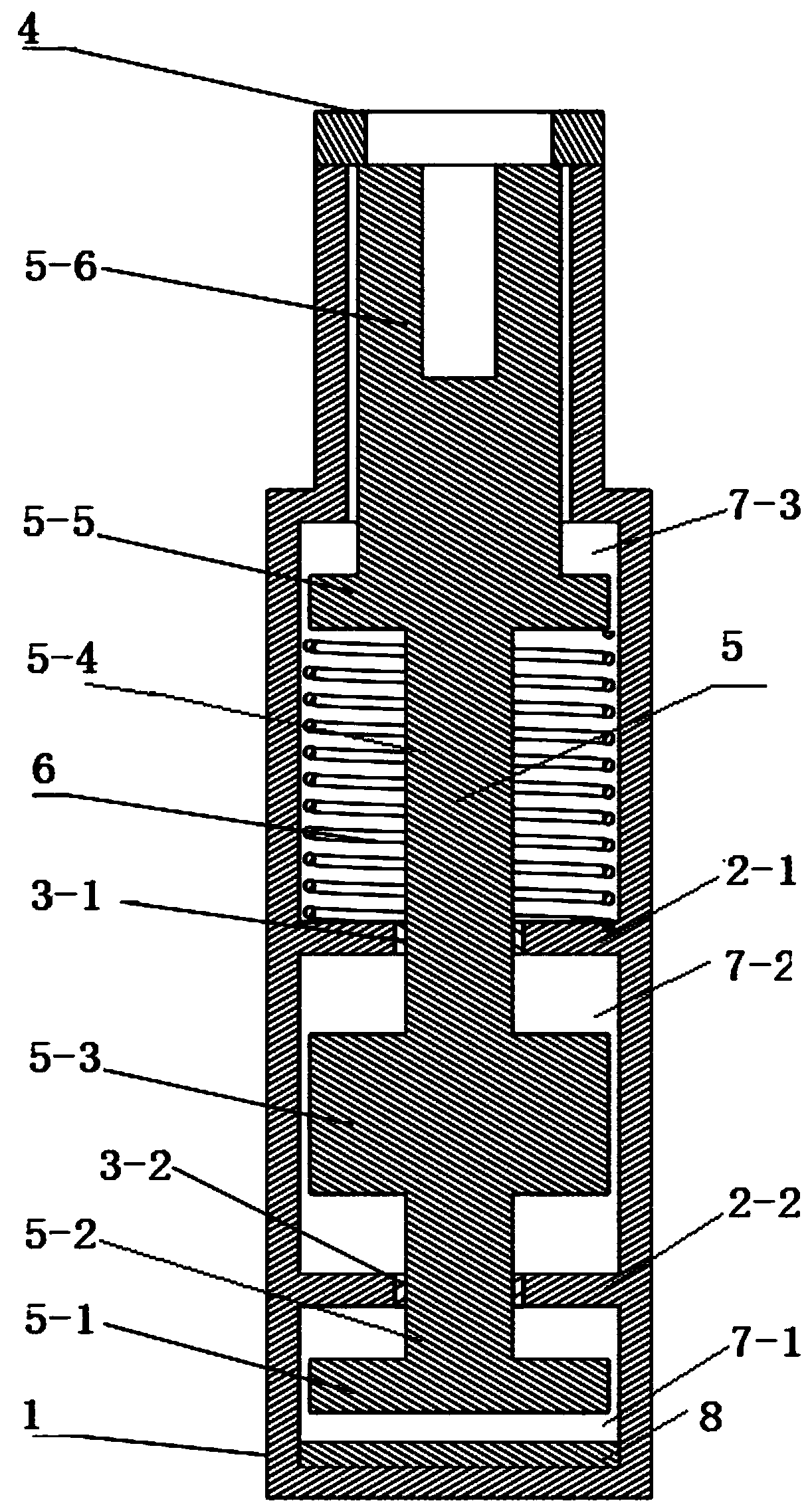

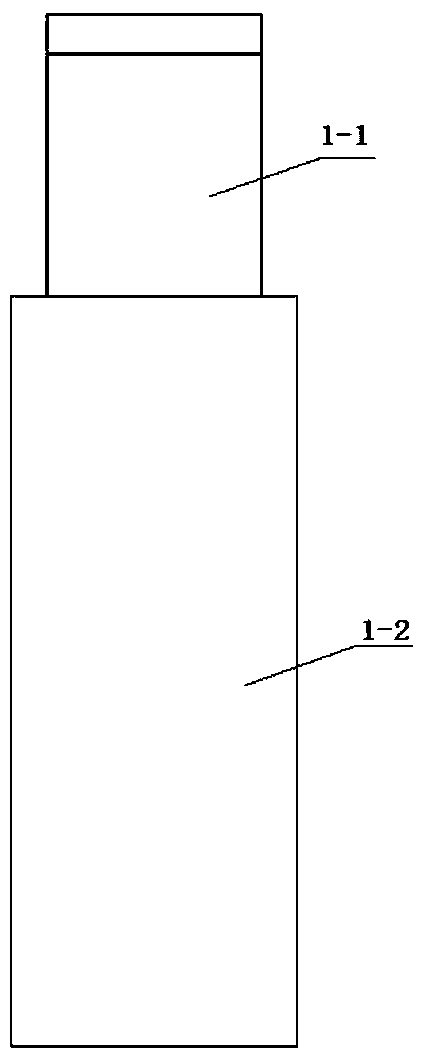

[0042] like figure 1 As shown, a spring cement shock absorber, the shock absorber includes a cylindrical cylinder 1 with a boss on the top and a shock absorbing member arranged in the cylinder 1, and the cylindrical cylinder 1 includes an upper cylinder 1- 1 and the lower cylinder body 1-2, the upper cylinder body 1-1 is provided with a limit ring 4 equal to its outer diameter, and the damping member includes a piston rod 5 and a spring 6 coaxially arranged with the cylinder body 1 ; The piston rod 5 is a cylindrical lower limit block 5-1, a connecting rod I 5-2, a piston 5-3, a connecting rod II 5-4, an upper limit block 5-5 and a connecting piece coaxially arranged in sequence from bottom to top Ⅲ5-6, the inner wall of the lower cylinder 1-2 is provided with an annular upper partition 2-1 and a lower partition 2-2 to divide the inner cavity of the lower cylinder 1-2 into an upper cavity 7-1, a middle cavity Body 7-2 and lower cavity 7-3, the upper partition 2-1 and the lowe...

Embodiment 2

[0055] The structure is consistent with Example 1, wherein:

[0056] The inner diameter of the upper shell 1-1 is 5 / 6 of the inner diameter of the lower shell 1-2;

[0057] The outer diameter of the connecting rod III5-6 is 15 / 16 of the inner diameter of the upper shell 1-1, and the height of the connecting rod III5-6 is 1.2 times the height of the upper shell 1-1;

[0058] The outer diameter of lower limit block 5-1, piston 5-3 and upper limit block 5-5 is equal to 15 / 16 of the inner diameter of lower shell 1-2, and the outer diameter of connecting rod Ⅰ 5-2 and connecting rod Ⅱ 5-4 is equal to piston 5 -3 1 / 2 of the outer diameter;

[0059] The radial thickness of the annular sealing ring 3 is 1 / 20 of the outer diameter of the connecting rod;

[0060] The raw materials used for the preparation of shock-absorbing rubber include the following components in parts by mass: 50 parts of nitrile rubber, 50 parts of hydrogenated nitrile rubber, 30 parts of carboxylated nitrile rub...

Embodiment 3

[0063] The structure is consistent with Example 1, wherein:

[0064] The inner diameter of the upper shell 1-1 is 1 / 2 of the inner diameter of the lower shell 1-2;

[0065] The outer diameter of the connecting rod III5-6 is 5 / 8 of the inner diameter of the upper shell 1-1, and the height of the connecting rod III5-6 is 1.1 times the height of the upper shell 1-1;

[0066] The outer diameter of lower limit block 5-1, piston 5-3 and upper limit block 5-5 is equal to 5 / 8 of the inner diameter of lower shell 1-2, and the outer diameter of connecting rod Ⅰ 5-2 and connecting rod Ⅱ 5-4 is equal to piston 5 -2 / 5 of the outer diameter of 3;

[0067] The radial thickness of the annular sealing ring 3 is 1 / 30 of the outer diameter of the connecting rod;

[0068] The raw materials used for the preparation of shock-absorbing rubber include the following components in parts by mass: 40 parts of nitrile rubber, 40 parts of hydrogenated nitrile rubber, 25 parts of carboxylated nitrile rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com