LED mirror front lamp

A technology of mirror headlights and lamp holders, which is applied in the field of mirror headlights, can solve the problems of LED chips not being resistant to high temperature, inconvenient installation and disassembly of mirror headlights, etc., and achieves convenient and quick disassembly, cleverness involved, and improved energy utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

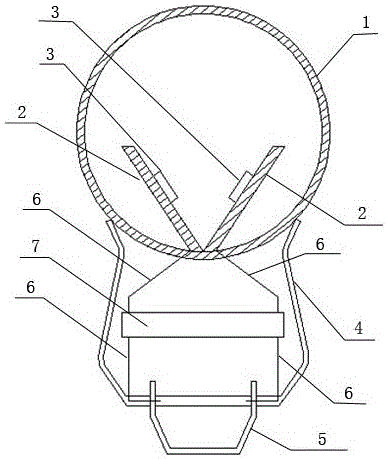

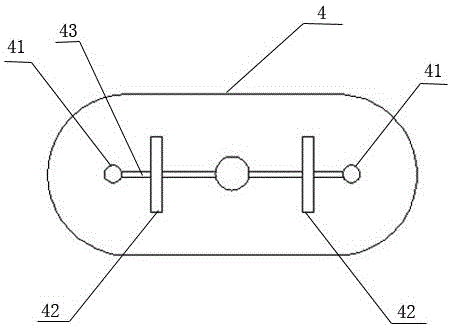

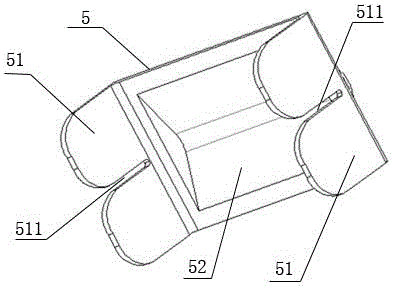

[0023] like figure 1 As shown, a clip-on LED mirror headlight includes a lampshade 1, a light source board, a lamp holder plastic part 4, hardware parts 5, wires 6, and a driving board 7. The cross-section of the lamp cap plastic part 4 is a U-shaped structure, such as figure 2 As shown, a threading hole 41 is respectively provided on both sides of the lower end surface of the lamp holder plastic part 4 , and two bayonets 42 are provided on the opposite inner sides of the two threading holes 41 . The lampshade 1 is installed on the upper end surface of the lamp holder plastic part 4 . The light source board is arranged in the lampshade 1, and the light source board includes an aluminum substrate 2 and an LED light source board 3. The driving board 7 is installed in the plastic part 4 of the lamp cap. like image 3 As shown, the hardware 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com