Efficient ultrasonic cleaner capable of continuously cleaning

A technology of ultrasonic wave and cleaning instrument, which is applied in the field of high-efficiency ultrasonic cleaning instrument, which can solve the problems of affecting the cleaning efficiency of the device, the lack of cleaning structure of impurities, and the short time for salvaging and draining, so as to increase the efficiency, increase the limit, Easy to disassemble for cleaning or replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

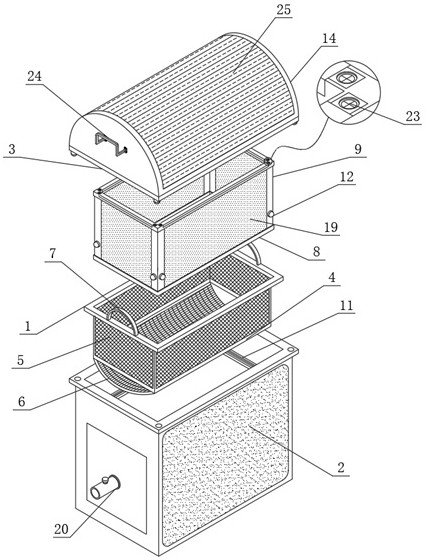

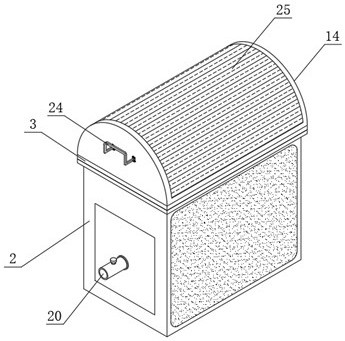

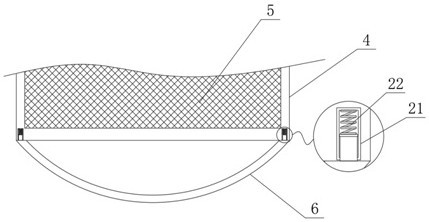

[0030] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , an embodiment provided by the present invention, a high-efficiency ultrasonic cleaner capable of continuous cleaning, including a limit frame 1, a bottom frame 8 and a clamping frame 11, the inner wall of the ultrasonic cleaner body 2 is connected to the limit frame 1, The top of the ultrasonic cleaning instrument body 2 is plugged with the limit cover 3, the limit frame 1 is installed on the inner side of the bottom of the limit frame 4, the limit frame 4 is provided with a limit grid frame 5 on the inner wall, and the bottom of the limit frame 4 is connected with a connecting network Frame 6, the front end and the tail end of the limit frame 1 top are all provided with limit grip 7, the inwall of limit grid frame 5 is clamped with bottom frame 8, and the top of bottom frame 8 is equipped with plug-in board 9, plug-in board The top of 9 is equipped with a top frame 10, the top of the top frame 10 is fi...

Embodiment 2

[0033] see figure 1 , figure 2 , Figure 6 and Figure 7 , an embodiment provided by the present invention, a high-efficiency ultrasonic cleaner capable of continuous cleaning, including a limit cover 3, a pressing block 12 and a plugging block 13, and a clamping frame 11 is installed on the inner wall of the ultrasonic cleaner body 2 , the limit frame 1 is clamped on the top of the clamp frame 11, the outer surface of the plug plate 9 is fitted with a pressing block 12, and the bottom of the limit cover 3 is surrounded by a plug block 13, and the plug block 13 is plugged into the top of the body 2 of the ultrasonic cleaner, a protective cover 14 is installed on the top of the limit cover 3, limit sliders 15 are arranged on both sides of the pressing block 12, and the limit slider 15 is slidably connected to the plug-in plate 9 Inside, the tail end of the pressing block 12 is provided with a pressing rod assembly 16, and the tail end of the pressing rod assembly 16 is fitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com