System and method for testing single noise quality in multi-source noise environment

A technology of source noise and environment, applied in the direction of measuring ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., to achieve the effect of convenient operation, easy implementation, and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

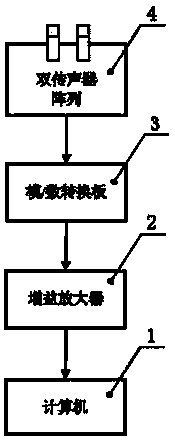

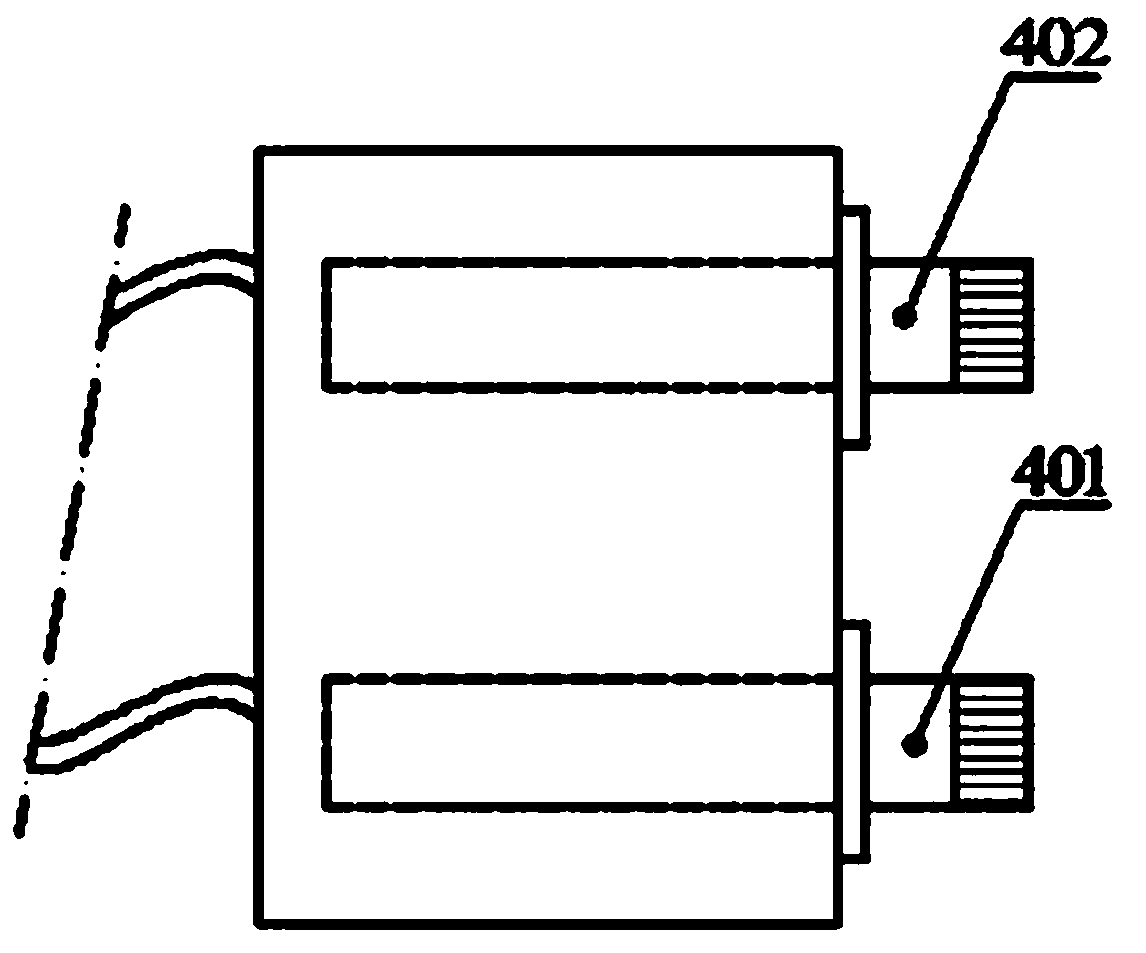

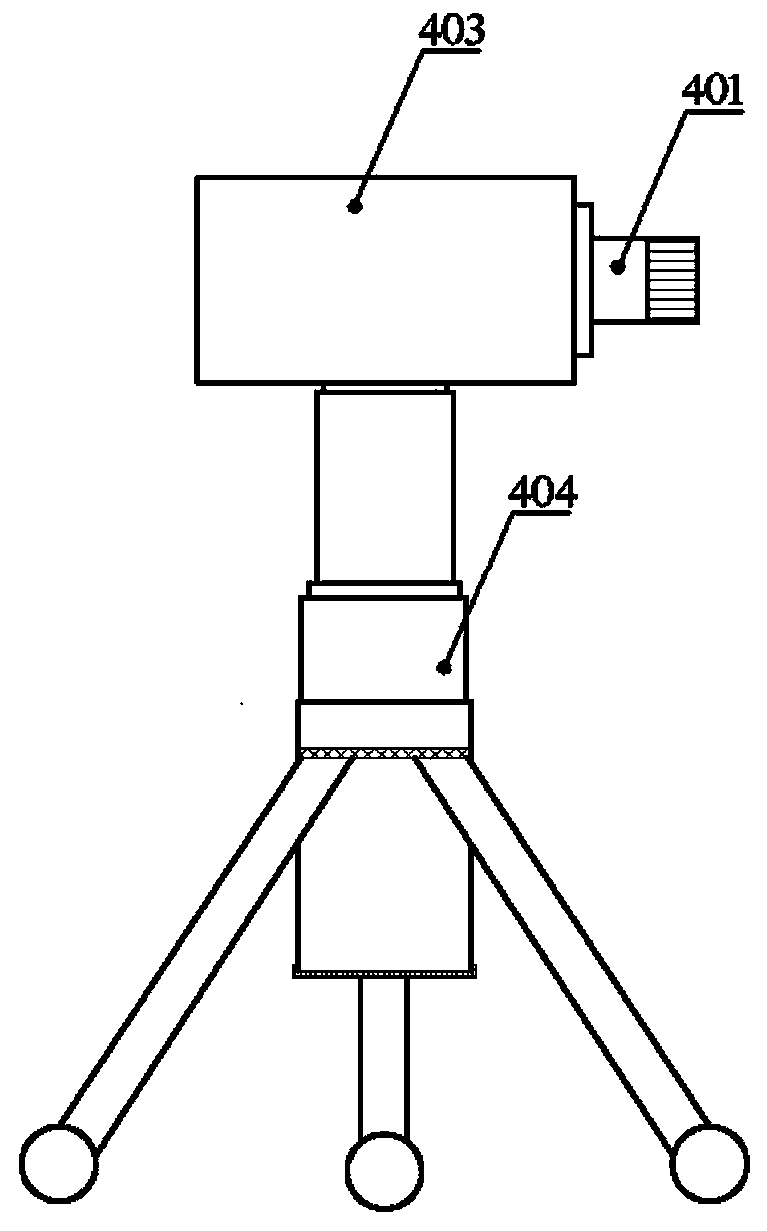

[0029] The system for testing single noise quality in the multi-source noise environment in this embodiment, such as figure 1 As shown, 1 in the figure is a computer, and 4 is a double microphone array, and this double microphone array 4 is two microphones 401 and microphone 402 arranged side by side; The output end of the analog / digital conversion board 3 is connected to the input end of the gain amplifier 3, and the output end of the gain amplifier 3 is connected to the input end of the computer 1 with a built-in signal processing module, a result output display module and a control module.

[0030] The computer 1 in this embodiment is used to control signal collection, process data and calculate sound intensity and sound quality parameters.

[0031] The gain amplifier 2 in this embodiment is used to amplify the collected signal and filter the interference signal.

[0032] The A / D conversion board 3 in this embodiment is used to convert the analog voltage signal generated b...

Embodiment 2

[0035] The difference between the system for testing a single noise quality in a multi-source noise environment in this embodiment and Embodiment 1 is that the distance between the centers of the microphone 401 and the microphone 402 is 50 mm, and the corresponding test range is 30 Hz to 1200 Hz.

Embodiment 3

[0037] The difference between the system for testing a single noise quality in a multi-source noise environment in this embodiment and Embodiment 1 is that the microphone 401 and the microphone 402 are both standard 1 / 4-inch microphones, the distance between centers is 6 mm, and the corresponding test range is 6000 to 12000Hz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com