Array substrate and manufacturing method thereof and display device

A technology of an array substrate and a manufacturing method, which is applied in the display field and can solve the problems of small viewing angle and single deflection angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

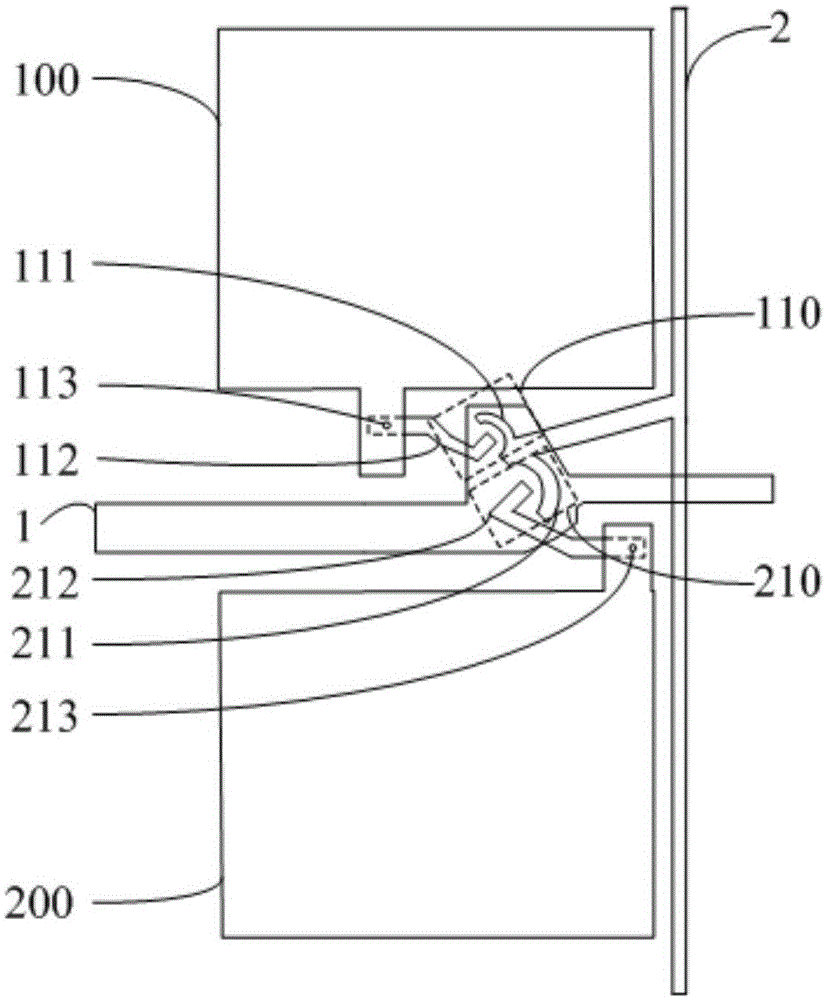

[0098] Such as figure 1 As shown, the pixel unit specifically includes a first sub-pixel electrode 100 and a second sub-pixel electrode 200, and a first charging thin film transistor 110 and a second charging thin film transistor 210. The first charging thin film transistor 110 includes a charging source 111, a charging drain electrode 112 and charging grid (the charging grid corresponds to the channel between the charging source 111 and the charging drain 112 in the figure, and is located at the lower layer of the source-drain metal layer where the source 111 and the drain 112 are located and the gate line 1 electrical connection, not shown in the figure), the second charging thin film transistor 210 includes a charging source 211, a charging drain 212 and a charging gate (the charging gate is electrically connected to the gate line 1, and the charging The gate is located below the channel between the charging source 211 and the charging drain 212 in the figure, and is locate...

Embodiment 2

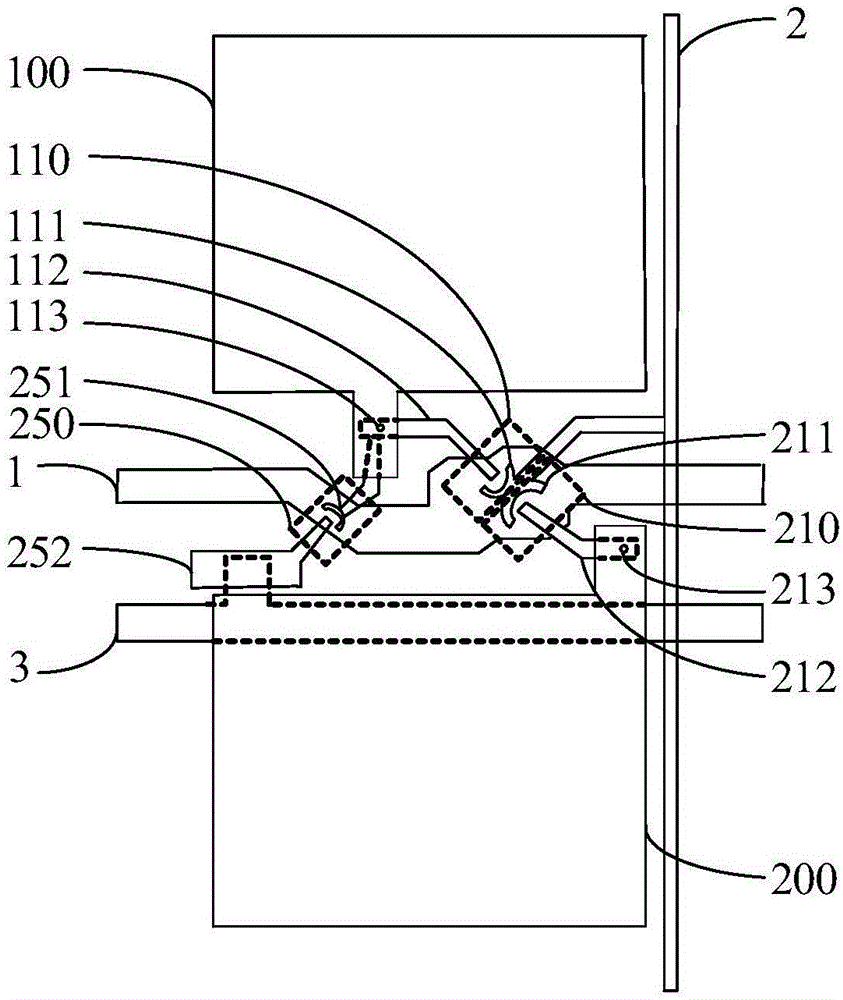

[0104] Such as figure 2 As shown, in this embodiment, in the same pixel unit, a voltage-dividing thin film transistor 250 is also included. The voltage-dividing thin film transistor 250 includes a voltage-dividing source 251, a voltage-dividing drain 252, and a gate. The voltage-dividing source 251 and The first sub-pixel electrode 100 is electrically connected, a voltage-dividing drain 252 is formed corresponding to the voltage-dividing source 251, a channel is formed between the voltage-dividing source 251 and the voltage-dividing drain 252, and the voltage-dividing drain 252 extends to the common electrode line 3 Directly above , together with the common electrode line 3 constitute a step-down storage capacitor. In the embodiment of the present invention, a specific setting method of the voltage-dividing thin film transistor 250 and the step-down storage capacitor is provided, but it is not limited thereto. Those skilled in the art can set the voltage-dividing thin film tr...

Embodiment 3

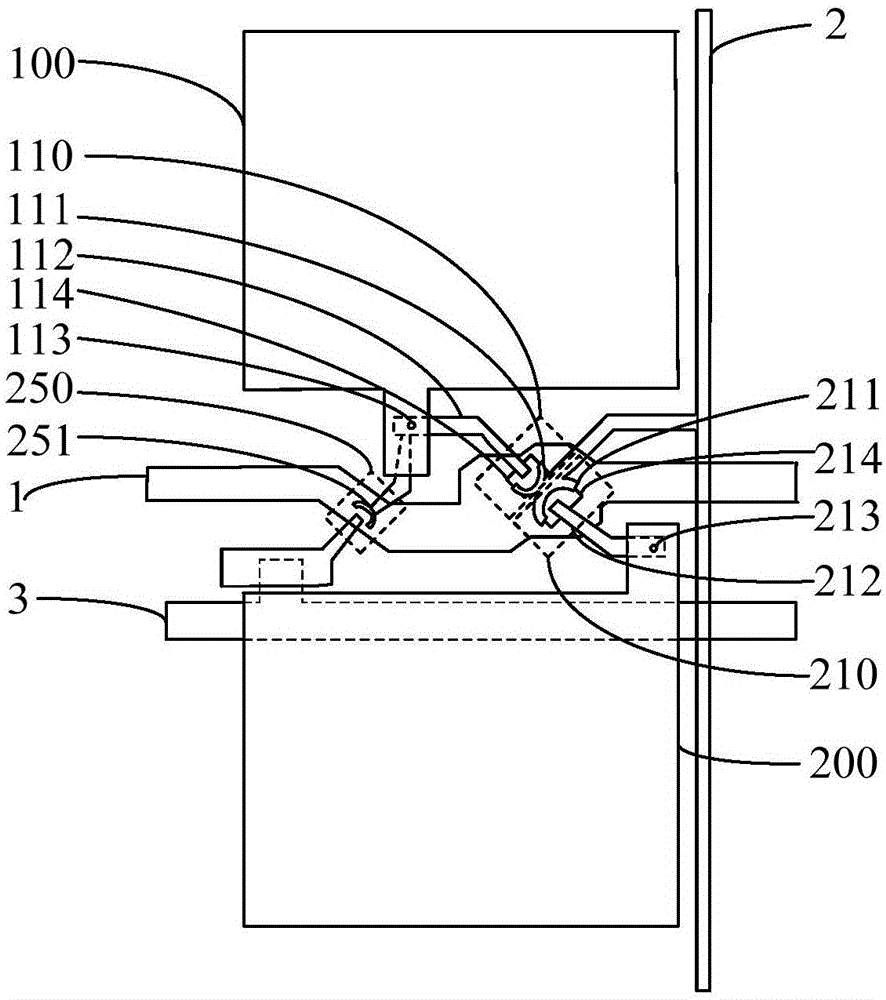

[0106] Such as image 3 As shown, as mentioned above, the charging current of the thin film transistor is proportional to the aspect ratio and / or the carrier mobility of the active layer. Therefore, in this embodiment, by making the first charging thin film transistor The carrier mobility of the material of the active layer 114 in 110 is smaller than the carrier mobility of the material of the active layer 214 in the second charging thin film transistor 210, so as to further make the charging capability of the second charging thin film transistor 110 higher than that of the first charging thin film transistor. The charging capability of the charging TFT 210 is stronger, so that the charging voltage of the first sub-pixel electrode 100 is lower than the charging voltage of the second sub-pixel electrode 200 . Furthermore, the deflection angles of the liquid crystal molecules in the liquid crystal regions corresponding to the same pixel unit are different, and finally the viewin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com