Mechanical seal device with simplified structure

A mechanical seal and equipment technology, applied in the field of mechanical seal equipment provided with clamping connections, can solve problems such as inability to set supply pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

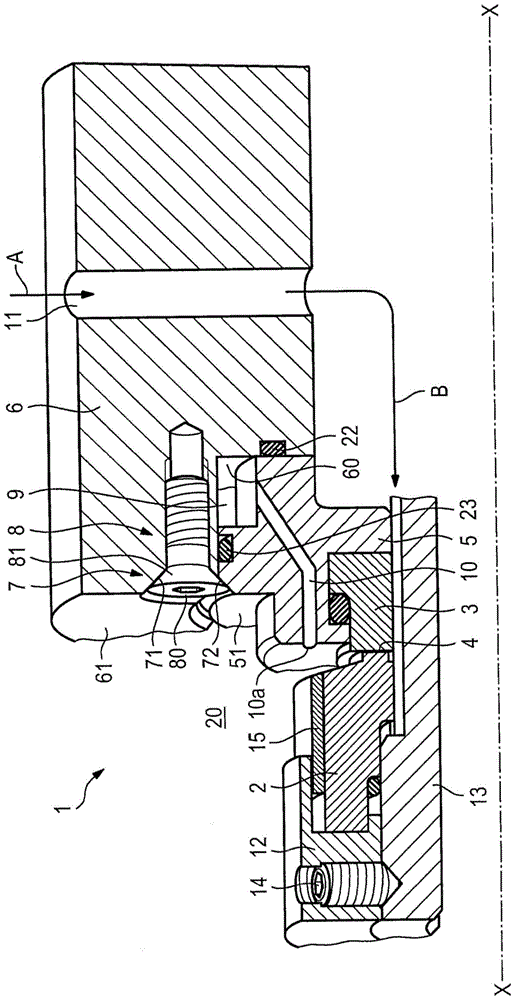

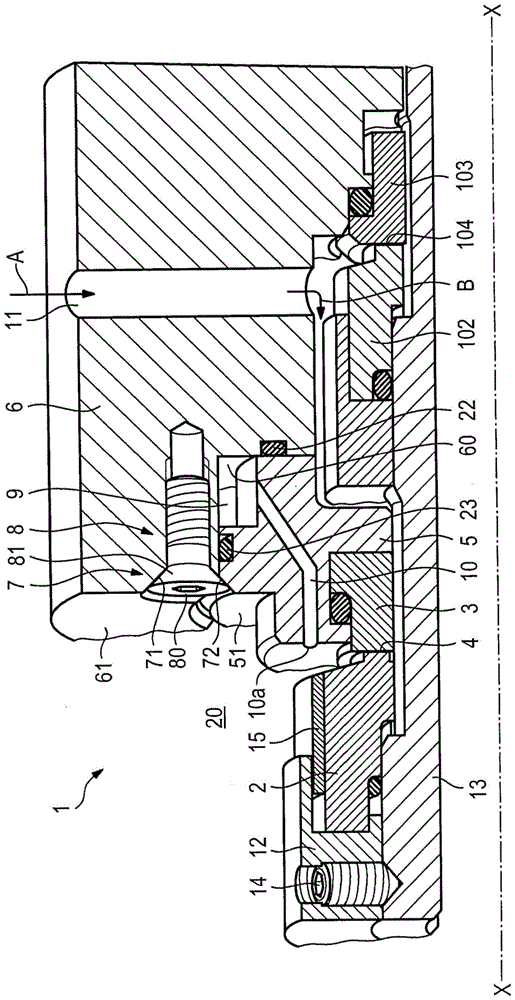

[0017] if possible from figure 1 It is observed that the mechanical seal device 1 according to the invention comprises a rotary slip ring 2 and a stationary slip ring 3 between which a sealing gap 4 is defined in a known manner. The outer periphery of the rotary slip ring 2 has a hoop 15 from which the rotation of a shaft (not shown) is transmitted to a sleeve 13 and from the sleeve 13 to a holder 12 connected to the sleeve 13 by a connecting screw 14 . The retainer 12 engages the outside of the hoop 15 and transmits torque to the rotary slip ring 2 .

[0018] The fixed slip ring 3 is connected to the one-piece housing 6 via a retaining ring 5 . if possible from figure 1 It is observed that the retaining ring 5 overlaps and fixes the slip ring 3 in the axial direction X-X of the mechanical seal device.

[0019] A clamping connection 7 is formed between the retaining ring 5 and the housing 6 . In this exemplary embodiment, the clamping connection 7 comprises a clamping elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com