Fertilizer applicator

A technology of a fertilizer applicator and a main frame, applied in the field of fertilizer applicators, can solve the problems of reduced crop yield, uneven fertilizer application, increased labor cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

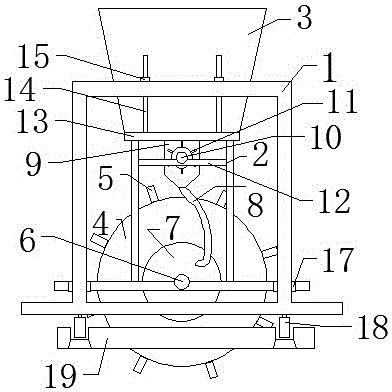

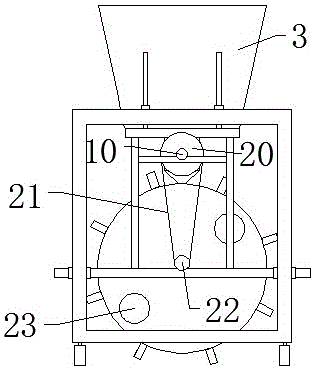

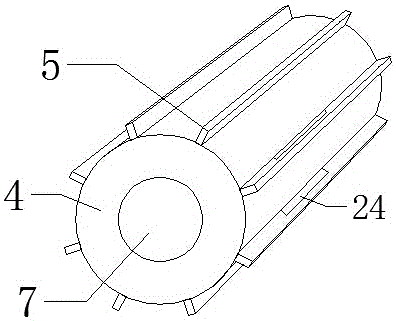

[0017] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 As shown, a fertilizer applicator includes a main frame 1, a sub-frame 2 arranged inside the main frame 1, and a slide rail 19 provided at the bottom of the main frame 1. The bottom of the sub-frame 2 is rectangular, and the length of the front side and the length of the rear side are at both ends. The clips 17 are respectively provided, and the clips 17 are fastened on the column of the main frame 1, and the rotation shaft 6 is set at the middle position between the front side length and the back side length of the bottom of the sub-frame 2, and the rotation shaft 6 passes through the baffle plate 25 set in the drum 4 and behind the drum 4 On the end face, the surface of the drum 4 is evenly equipped with a water-beating plate 5, and the water-beating plate 5 is provided with a water inlet 24 near the center of the drum 4, and the front end of the drum 4 is provided with a feeding opening 7, and the rear en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com