Sugarcane stripper

A defoliator and sugarcane technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of high cost, damage to sugarcane fields, high price, etc., and achieve high work efficiency, clean leaves, and easy replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

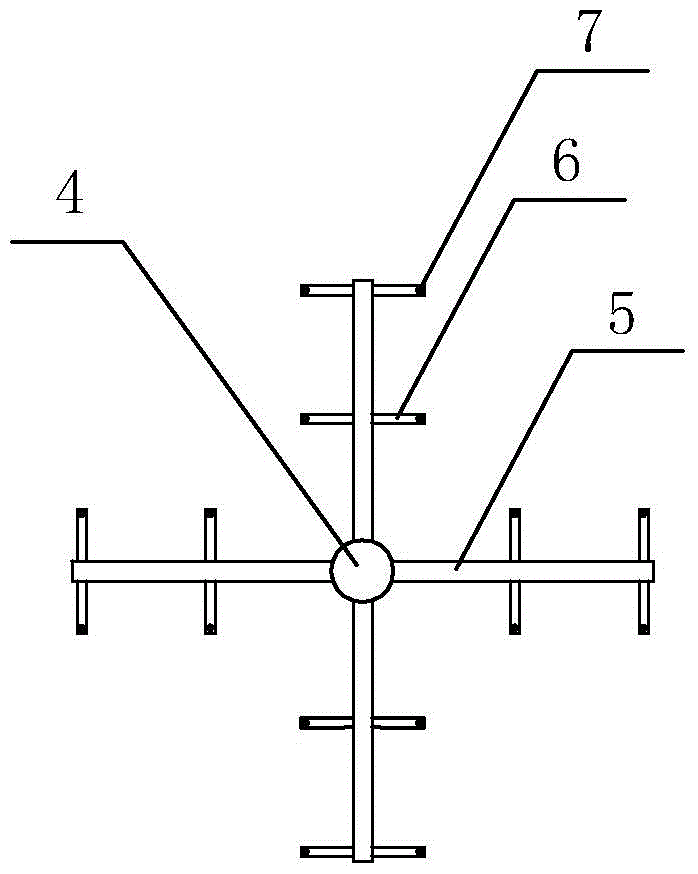

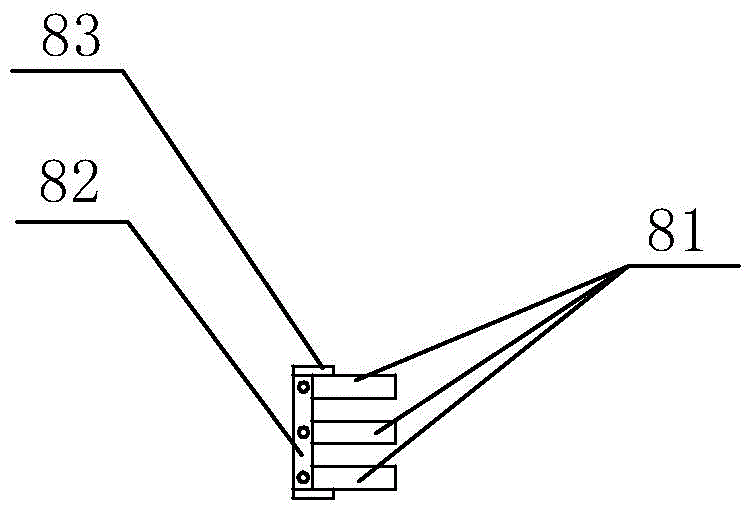

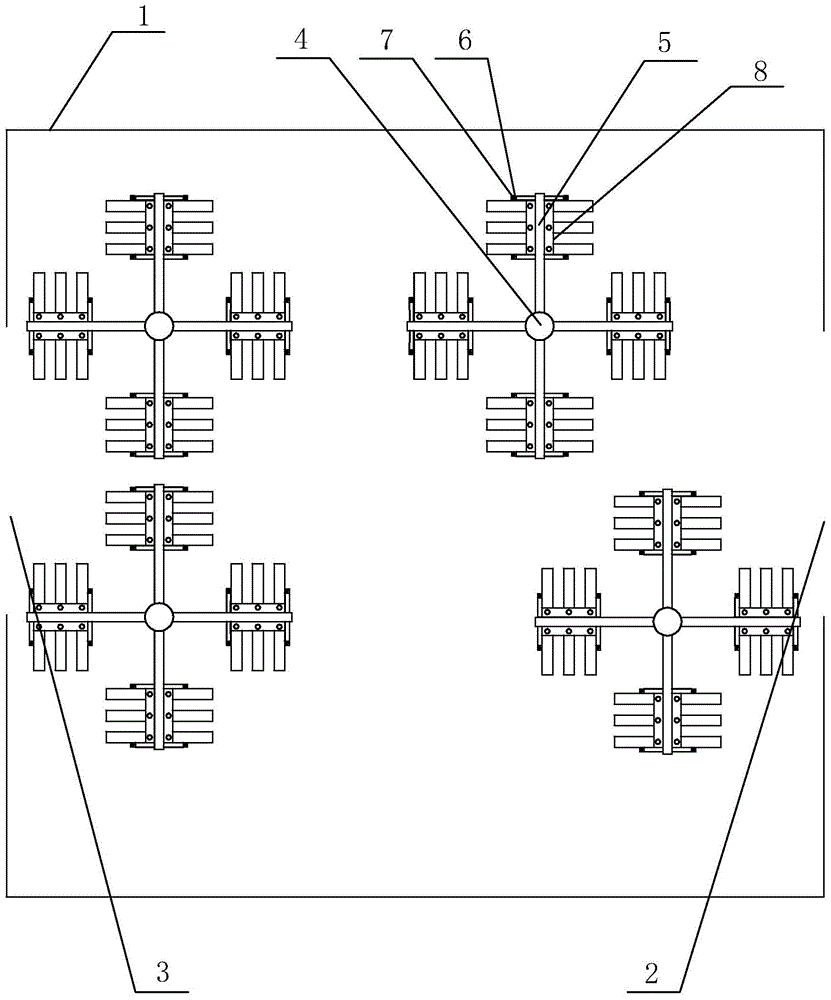

[0023] A sugarcane leaf stripper, comprising a casing 1, a transmission shaft 4 installed inside the casing 1 and a transmission device, the two sides of the casing 1 are respectively horizontally provided with a sugarcane inlet 2 and an outlet 3, and the transmission shaft 4 is arranged along the The inlet and outlet 3 are horizontally arranged in two rows and installed at the bottom of the casing 1. There are at least two transmission shafts 4 in each row. The shaft 4 is flush, and at least four fixed rods 5 are installed on the transmission shaft 4. The fixed rods 5 are on the same plane as the inlet 2 and the outlet 3 and are evenly distributed. The fixed rods 5 are symmetrically installed with There are 81 sets of 8 two rubber strips on the same plane as the inlet 2 and the outlet 3; it can peel several sugarcane leaves with different diameters and different curvatures at the same time, with high work efficiency, simple structure, small volume, and convenient field operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com